Construction method for dynamically monitoring stirring construction effect

A technology of dynamic monitoring and construction methods, applied in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as difficult to take remedial methods, unable to make up for waste of materials, and difficult to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

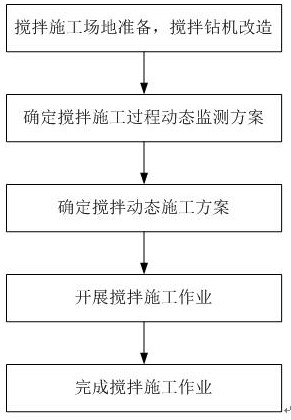

[0029] like figure 1 As shown, a construction method for dynamic monitoring of mixing construction effect is based on a mixing drill combined with a gamma ray detector and a mixing drill with multiple medium injection ports to carry out mixing construction operations and dynamically monitor the mixing effect. To dynamically adjust the stirring parameters, the specific steps are as follows:

[0030] Step 1: Mixing construction site preparation, mixing drilling rig modification;

[0031] According to the mixing design plan, the drilling operation is carried out at the central axis of the mixing pile body; the selected gamma ray detector is placed in the upper center of the mixing drill bit, connected with the inner wall of the drill bit through bolts, and the middle part of the mixing drill bit or the stirring blade Set several medium injection ports, the vertical distance between the gamma ray detector and the solidified material slurry injection port in the stirring drill bit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com