Drop test machine

A technology of testing machine and mechanical arm, which is applied in the direction of impact testing, testing of machine/structural components, measuring devices, etc. It can solve problems such as non-standard operation, low efficiency, and poor effect of drop testing, and achieve good structural firmness , high efficiency and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Due to the current drop test effect on the product is not good, the efficiency is relatively low, and it needs to be dropped manually according to the operating specifications, but since each manual operation method cannot be exactly the same, the difference in this process will cause each time The initial conditions of the drop test are all different, resulting in non-standard operation and unable to meet the needs of people's long-term use. Therefore, we designed a drop test machine based on the existing technical defects, which has high efficiency and does not require manual contact with the product. The drop test of the product can be completed, the use effect is good, and the operation is convenient.

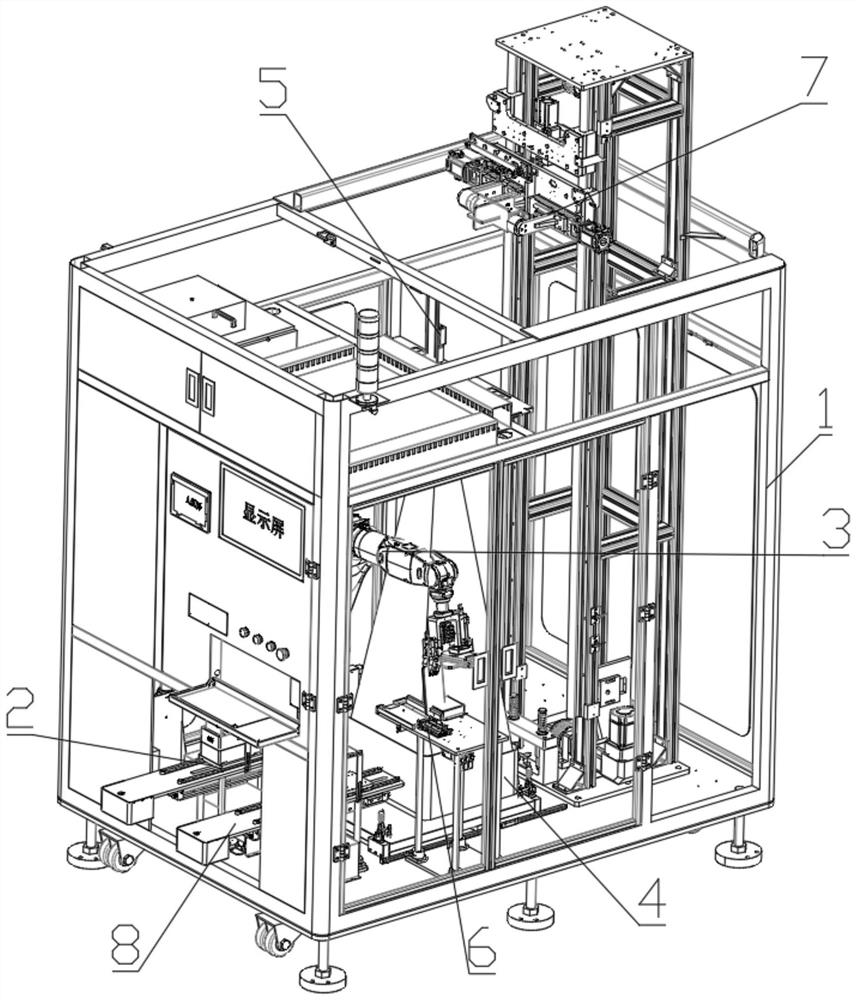

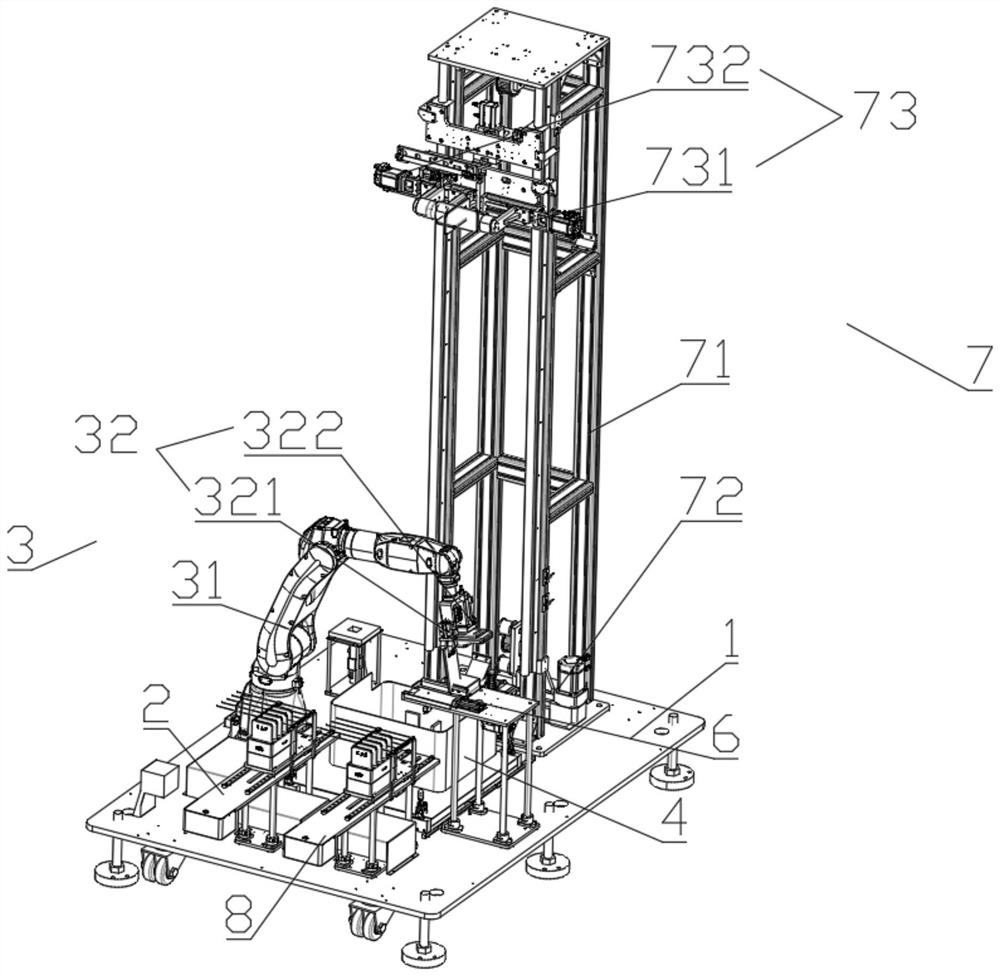

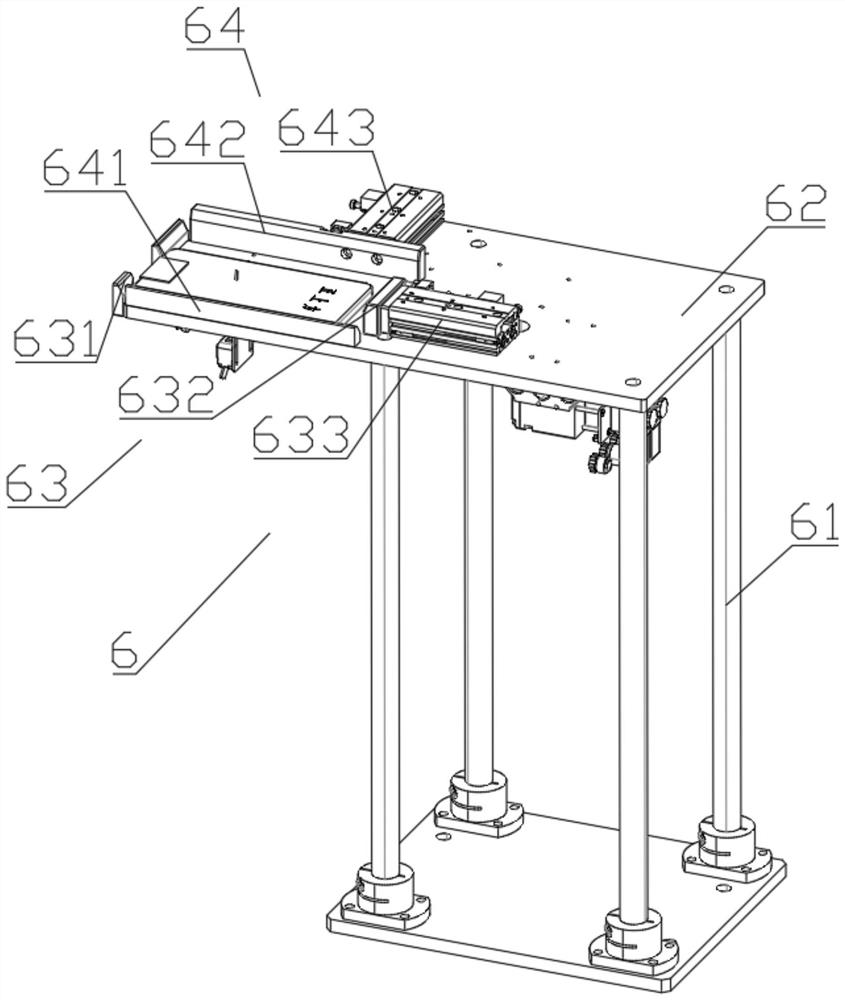

[0022] In order to facilitate those skilled in the art to make this technical solution more clear, the following will be combined with the attached figure 1 -4 Elaborate on the technical solution of the present invention: the drop test machine includes a support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com