Cement processing method

A processing method and cement technology, applied in chemical instruments and methods, dissolving, mixing machines, etc., can solve problems such as inability to move and mix cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described in detail with reference to the accompanying drawings.

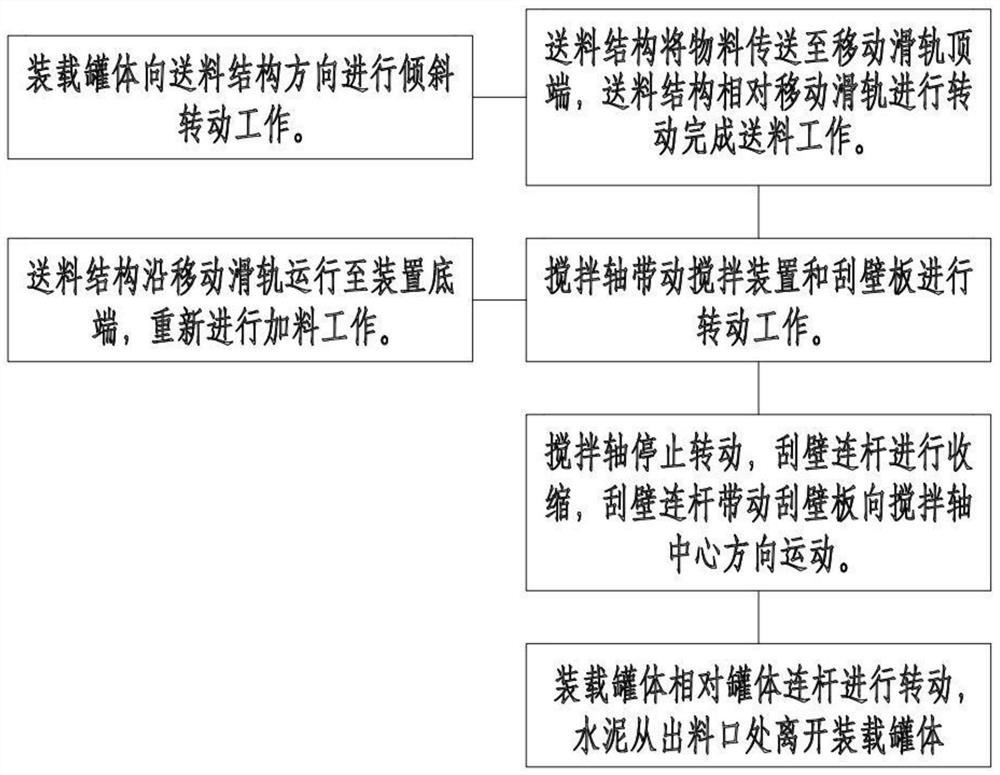

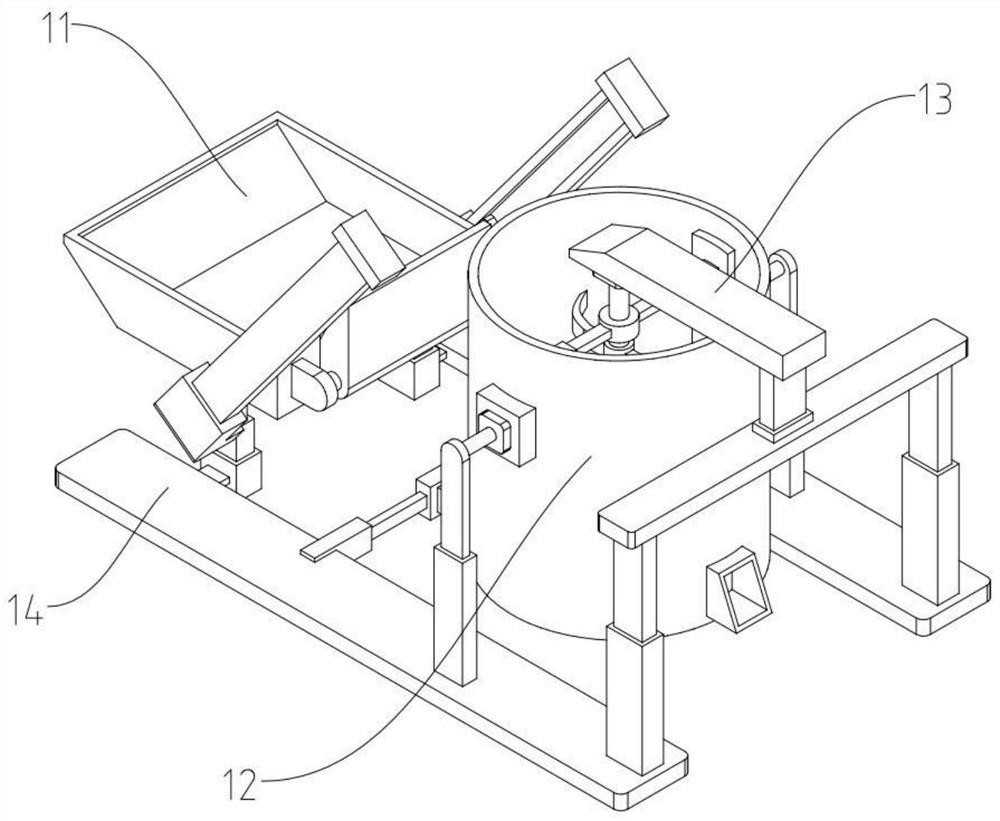

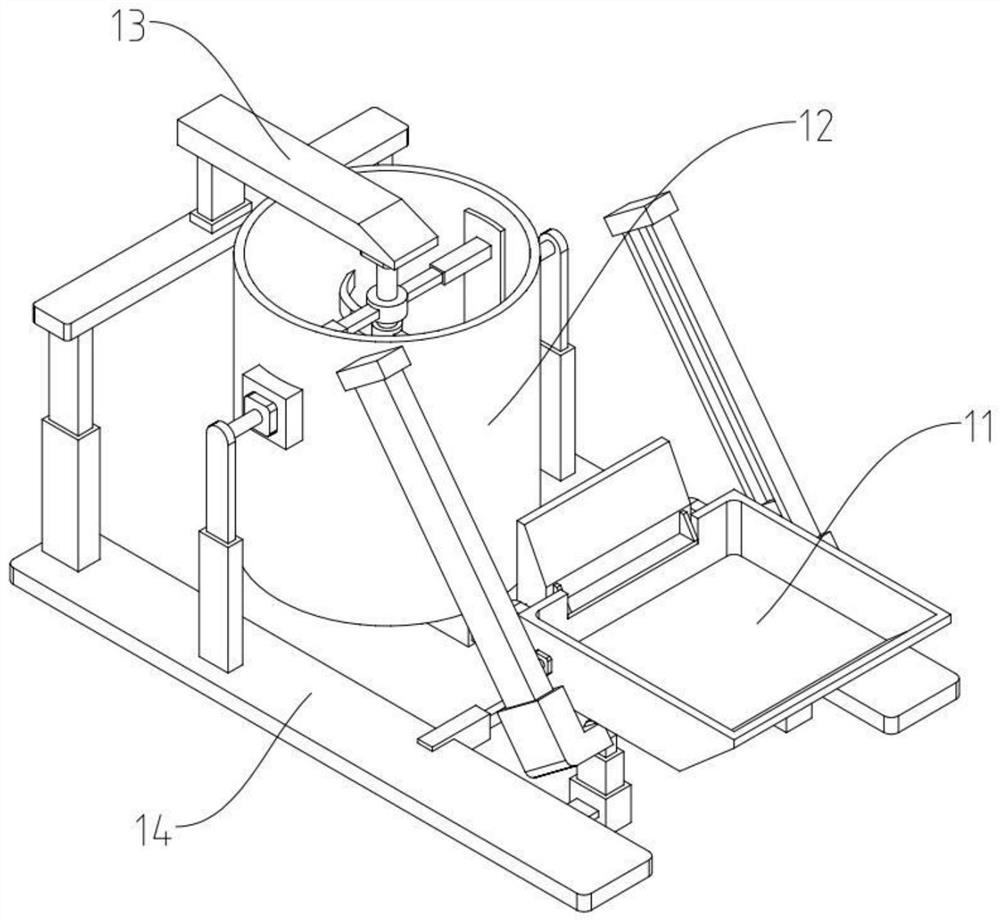

[0029] According to a kind of cement processing method of the present invention, embodiment combines Figure 1 to Figure 10 shown, where it can be seen that:

[0030] Attached below figure 2 , 3 , 4, 5, 6 for detailed description. The cement processing method can realize the automatic feeding and mixing work of the cement mixing work, and the whole cement mixing device can perform mobile operations. The main function realization parts of the cement processing method are the feeding structure 11 and the loading structure 12 . The feeding structure 11 and the loading structure 12 are both arranged on the supporting structure 14 , and both the feeding structure 11 and the loading structure 12 are fixedly connected to the supporting structure 14 . The feeding structure 11 is mainly convenient for the operator to add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com