Carbon fiber plate with soft covering layer and manufacturing method thereof

A carbon fiber board and covering layer technology, applied in the field of decorative boards, can solve the problems of limited strength and weather resistance of glued joints, unable to present carbon fiber texture, affecting physical health, etc., to improve fashion sense, facilitate promotion, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

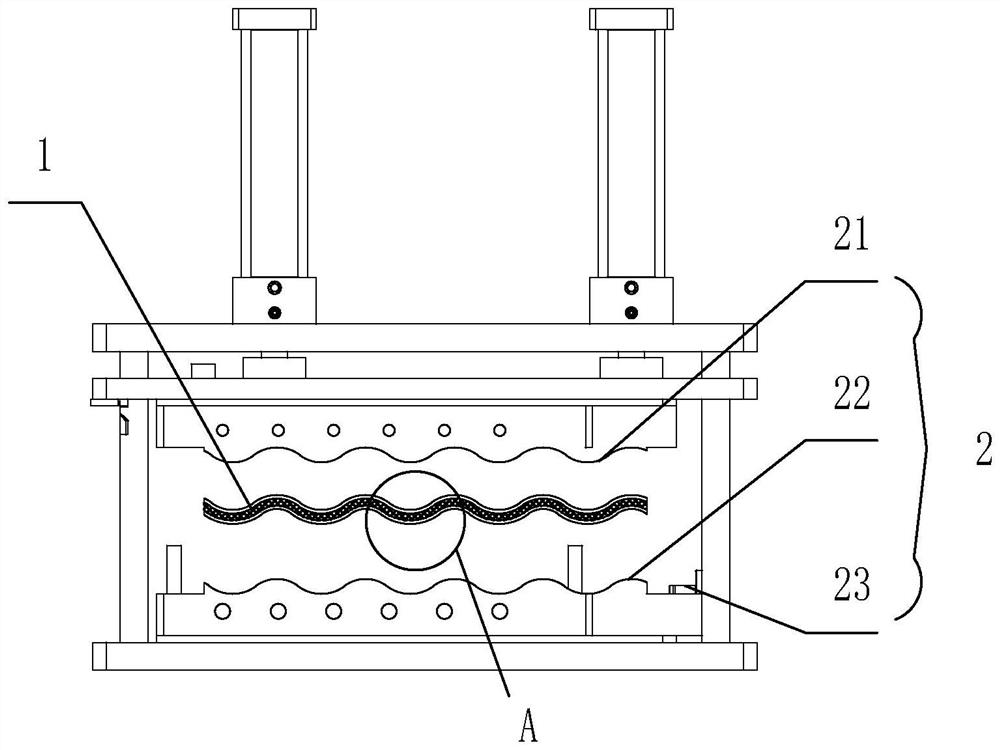

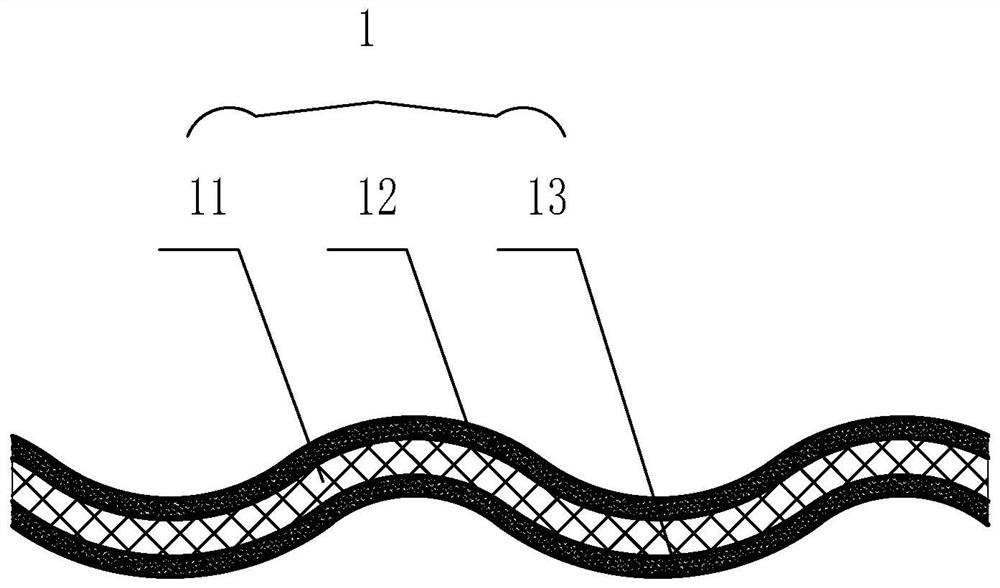

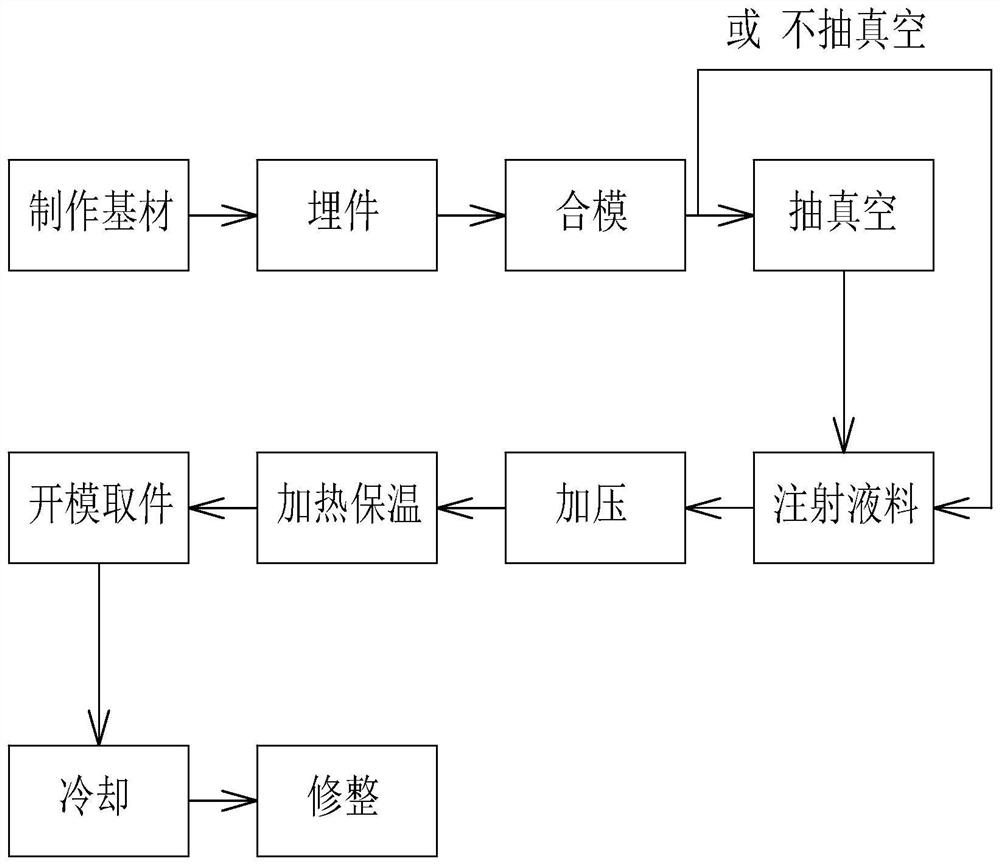

[0030] Such as figure 1 and figure 2 As shown, the carbon fiber plate (1) with a soft covering layer according to the present invention is that the covering layer formed by laying silica gel on the one-side surface or both-side surfaces of the plate-like carbon fiber base material is soft and transparent and the core It is a hard plate. The carbon fiber plate (1) includes a carbon fiber substrate (11) and a covering layer (12), the covering layer (12) is a soft transparent thin-walled silica gel film, and the covering layer (12) covers the carbon fiber substrate (11) on the surface. The covering layer (12) can be one-sided covering (not shown in the figure), which is covered on the upper or lower surface of the carbon fiber substrate (11); it can also be double-sided covering, which is covered on the carbon fiber The upper and lower sides of the substrate (11) are covered on both ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap