Piezoelectric micropump array, microsystem and thermal management method for microsystem

A micro-system and micro-pump technology, which is applied to components, pumps, and pump control of elastic fluid pumping devices, can solve problems that cannot meet the needs of high-efficiency micro-fluid cooling technology, and achieve improved cooling effects and improved The effect of output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

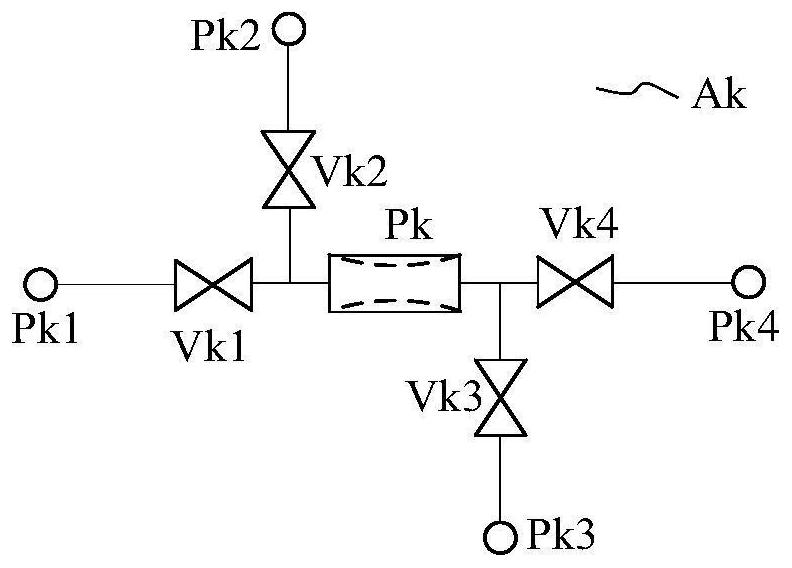

[0042] As mentioned above in the background technology, the inventor found that due to the technical limitations of the piezoelectric micropump, the working flow and output pressure of a single piezoelectric micropump cannot meet the needs of rapidly developing technologies such as micro-sprays and micro-channels. And other high-efficiency microfluidic heat dissipation technology needs.

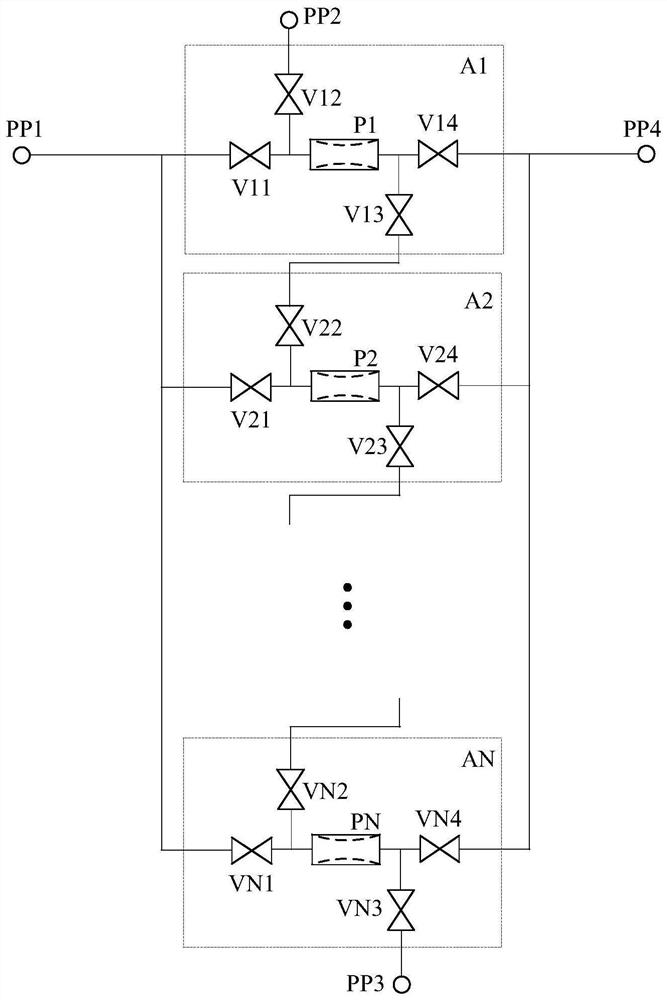

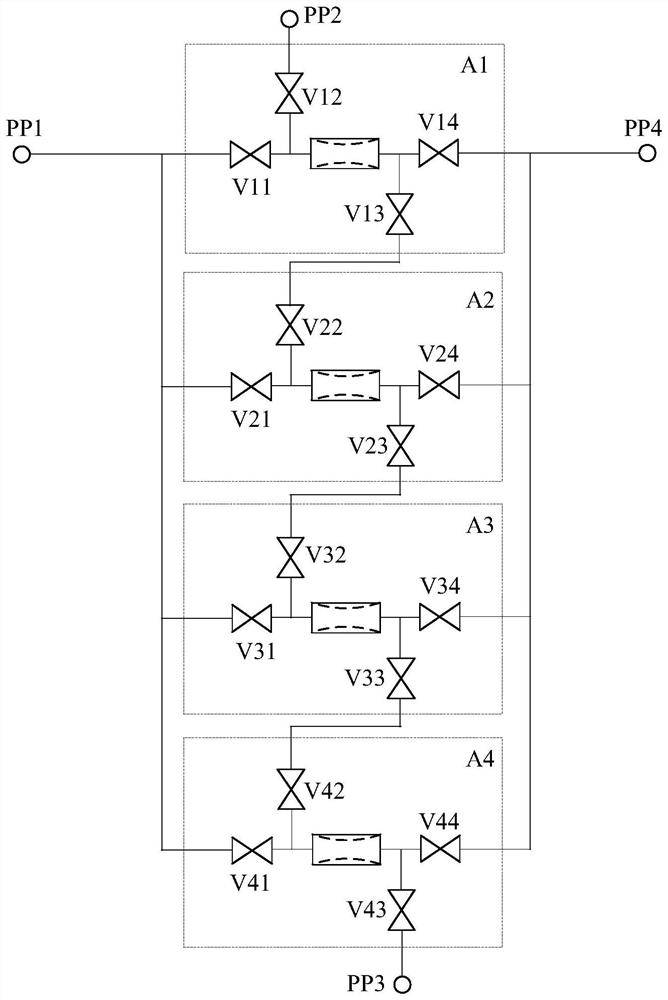

[0043] Based on this, the present invention proposes a brand-new piezoelectric micropump structure, which includes N piezoelectric micropump units connected in a distributed manner, and controls the on-off state of N piezoelectric micropump units through external electrical signals , to change the series-parallel state of N piezoelectric micropump units, the output pressure of the fluid can be increased when used in series, and the input and output flow of the fluid can be increased when used in parallel, so that it can effectively meet the large flow rate of the microfluidic heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com