Crawler belt transmission structure,crawler belt chassis and trowelling robot

A technology of crawler transmission and crawler chassis, which is applied in the direction of tracked vehicles, motor vehicles, building structures, etc., and can solve problems such as stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

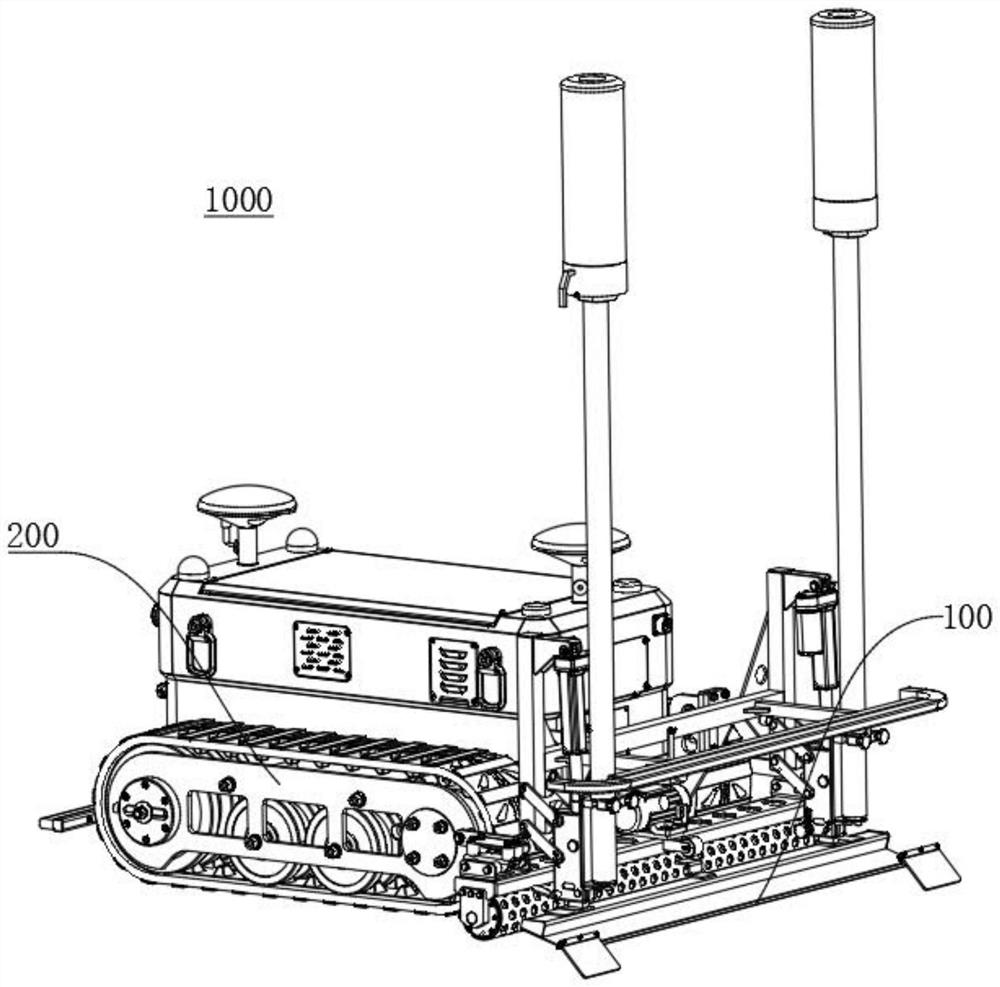

[0049] Please refer to figure 1 Embodiments of the present application provide a smooth robot 1000, including:

[0050] Slanting mechanism 100;

[0051] The track chassis 200, the clamping mechanism 100 is disposed in the chassis 210 of the track chassis 200 ( figure 2 Shows).

[0052] The squandering robot 1000 can be operated on the floor containing unsolved concrete by using the following track chassis 200, and it is difficult to travel due to concrete. For example, the squandering robot 1000 can be a glossy robot, and is equipped with components such as a splashing blade as a hlamping mechanism 100. The specific hlamping mechanism 100 can be selected according to the actual job needs.

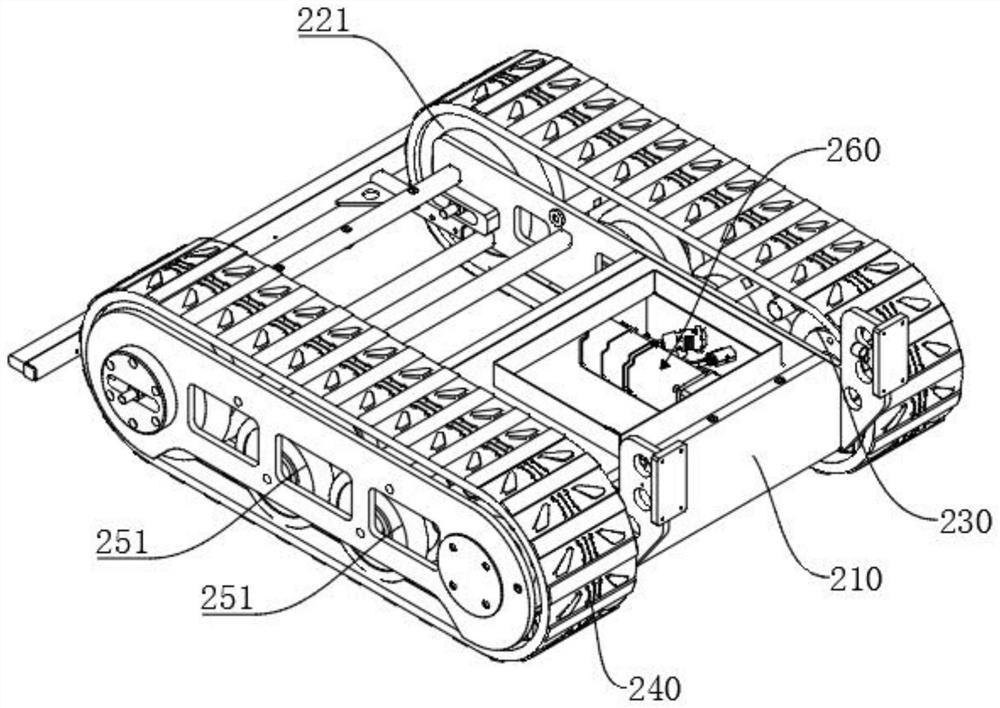

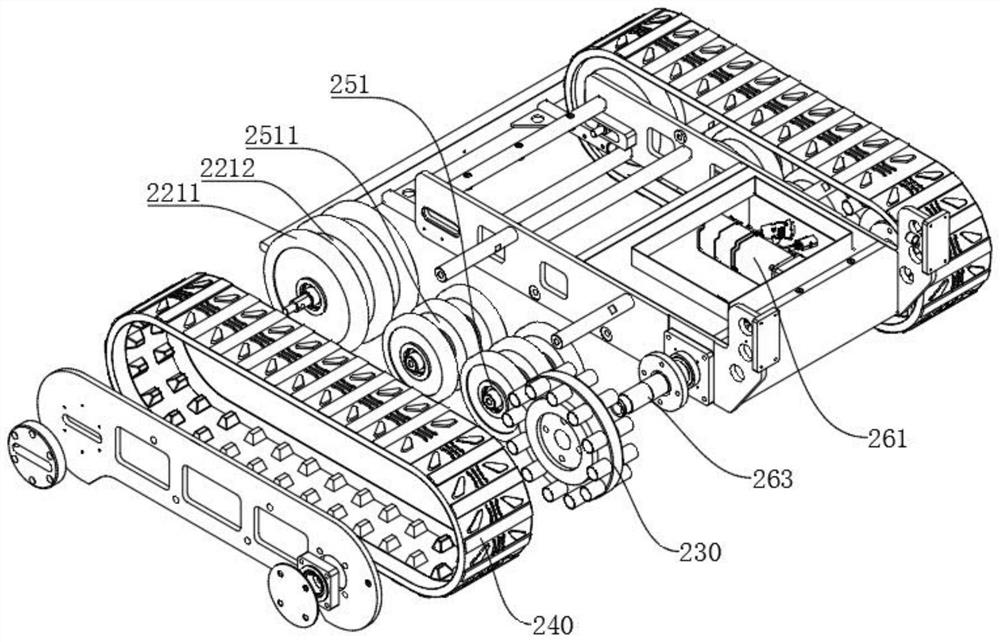

[0053] About the track chassis 200, specific, please combine figure 2 , image 3 as well as Figure 4 , Track chassis 200, including:

[0054] Character 210;

[0055] Terry wheel 221; and

[0056] The track drive structure, the tension wheel 221, and the track wheel 230 (below) are all provided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com