Micro-trigger pen

A micro-trigger and displacement technology, applied in printing, writing utensils, writing parts, etc., can solve problems such as poor trigger sensitivity, and achieve the effects of reducing assembly difficulty, improving user experience, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

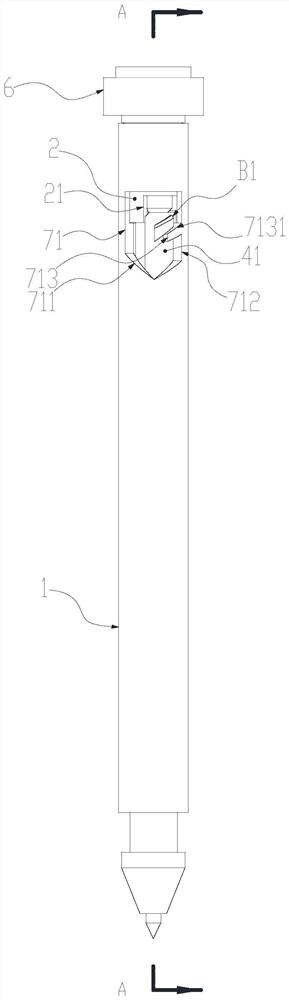

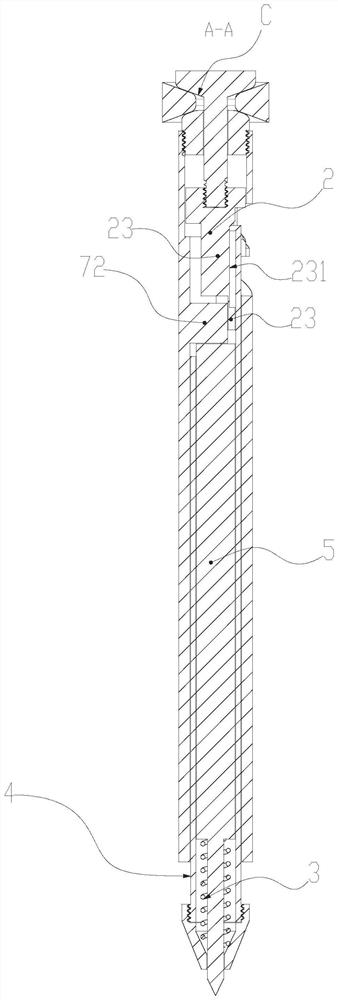

[0101] Such as Figures 1 to 2 A micro-trigger pen shown includes an outer rod 1, a reset member 3, a writing instrument body 5 and an adjustment module. The above adjustment module includes a control part 2 , an adjustment part 4 and a trigger assembly 6 .

[0102] A control rod 21 is arranged on the above-mentioned control member 2 .

[0103] The outer rod 1 is provided with a positioning slot 71 and a positioning portion 72 . The positioning groove 71 is provided with a core retracting switching wall 711 , a core retracting limiting wall 712 and a core exiting boss 713 . The core-out boss 713 is provided with a core-out sliding wall 7131 .

[0104] The adjustment member 4 is provided with a displacement member 41 , and the displacement member 41 moves in the positioning groove 71 .

[0105] The writing instrument main body 5 and the reset member 3 are placed in the adjustment member 4 , and the reset member 3 is specifically located between the writing instrument main b...

Embodiment 2

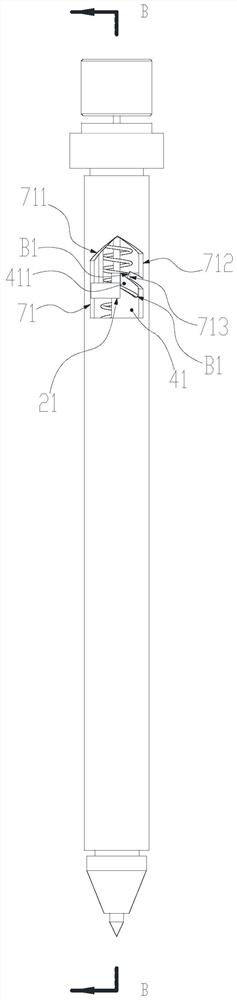

[0117] Such as Figures 3 to 4 A micro-trigger pen shown includes an outer rod 1, a reset member 3, a writing instrument body 5 and an adjustment module. The above adjustment module includes a control part 2 , an adjustment part 4 and a trigger assembly 6 .

[0118] A control rod 21 is arranged on the above-mentioned control member 2 .

[0119] The outer rod 1 is provided with a positioning groove 71 . The positioning groove 71 is provided with a core retracting switching wall 711 , a core retracting limiting wall 712 and a core exiting boss 713 . The core-out boss 713 is provided with a core-out sliding wall 7131 .

[0120] The adjustment member 4 is provided with a displacement member 41 , and the displacement member 41 moves in the positioning groove 71 .

[0121] The adjusting member 4 is also provided with an adjusting conflicting portion 42 and an adjusting pressing portion 43 . The above-mentioned writing instrument main body 5 and reset member 3 are placed inside ...

Embodiment 3

[0136] Such as Figures 5 to 9 A micro-trigger stylus is shown. It includes an outer rod 1, a reset member 3, a writing instrument main body 5 and an adjustment module. The above adjustment module includes a control part 2 , an adjustment part 4 , a trigger assembly 6 and a positioning part 7 .

[0137] A control rod 21 is arranged on the above-mentioned control member 2 .

[0138] Above-mentioned locating member 7 is installed in the outer bar 1, can not move up and down substantially, preferably do not move up and down. The above-mentioned positioning member 7 is provided with a positioning groove 71 . The positioning groove 71 is provided with a core retracting switching wall 711 , a core retracting limiting wall 712 and a core exiting boss 713 . The core-out boss 713 is provided with a core-out sliding wall 7131 .

[0139] The adjustment member 4 is provided with a displacement member 41 , and the displacement member 41 moves in the positioning groove 71 .

[0140] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com