Method and system for analyzing operation data of multiple high-speed rotating devices

A technology of equipment operation and high-speed rotation, applied to instruments, registration/indication of machine work, registration/instruction, etc., can solve problems such as low efficiency of manual data analysis, and achieve the effect of improving the level of monitoring and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

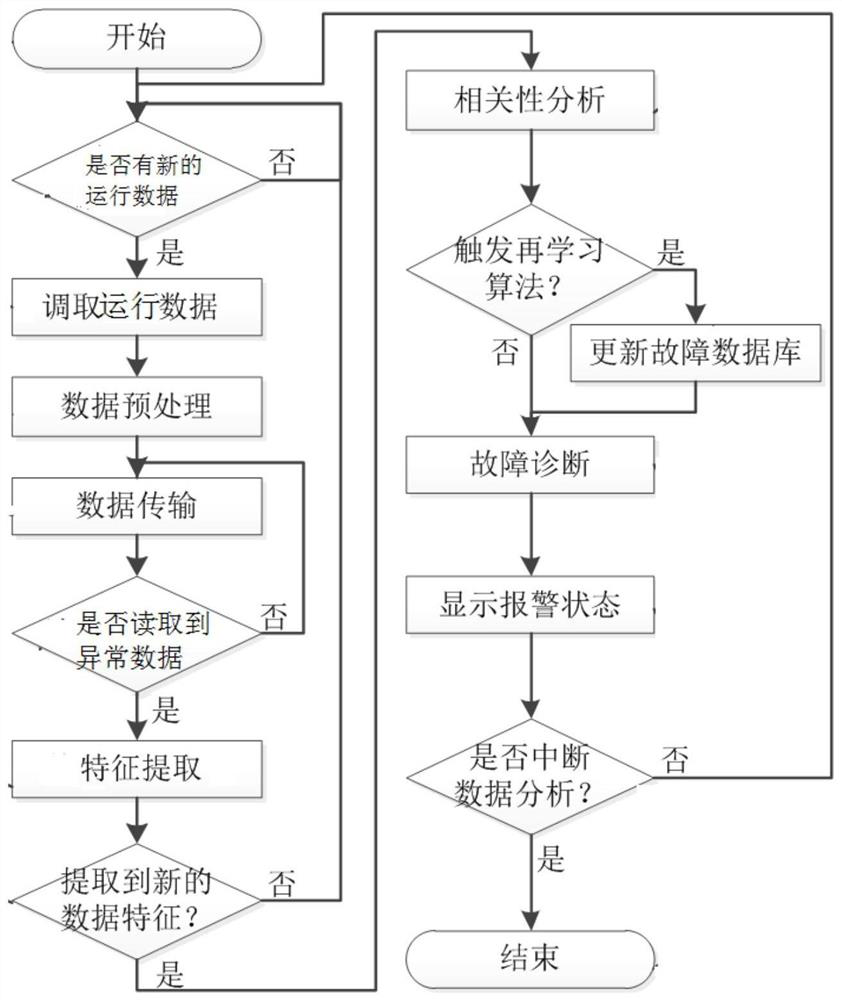

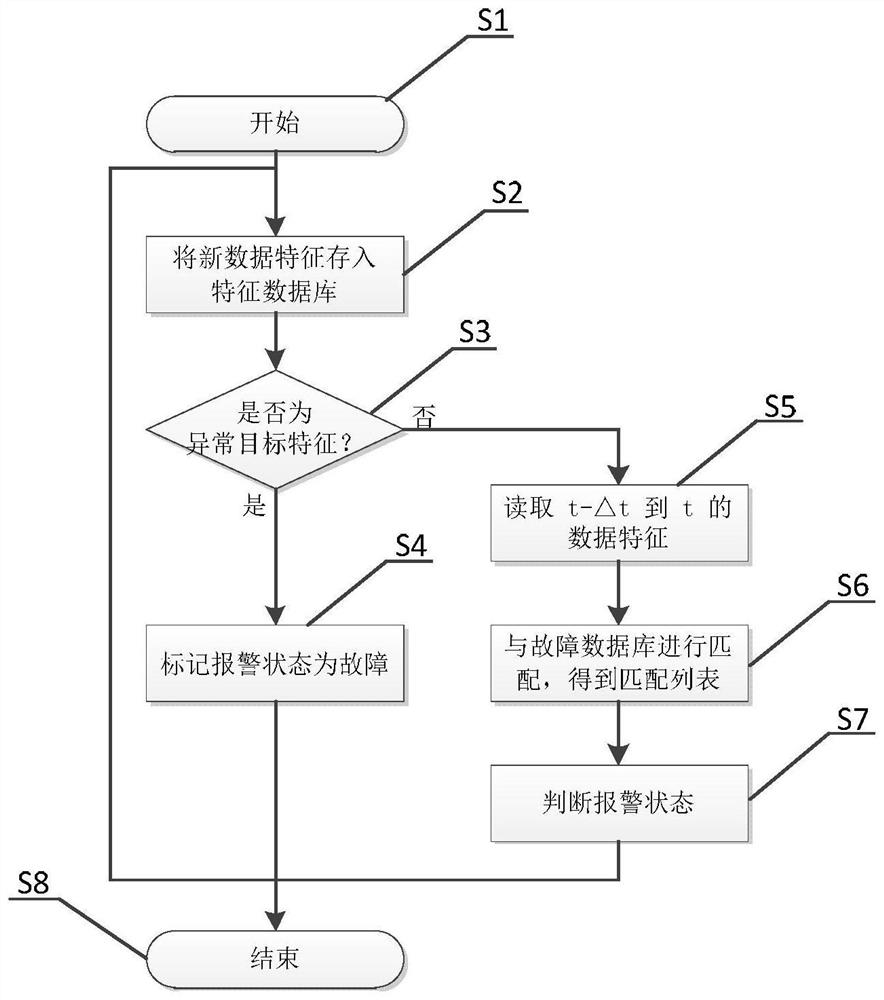

[0059] A method for abnormal analysis of operating data of multi-high-speed rotating equipment, such as figure 1 shown, including the following steps:

[0060] Start the multi-high-speed rotating equipment operation data analysis system, and the data analysis begins;

[0061] Step 1: The data retrieval module judges whether there is new operation data in the database of the multi-high-speed rotating equipment monitoring system. If there is new operation data, the data retrieval module retrieves the operation data and transmits it to the data preprocessing module, and the data preprocessing module Preprocessing the operating data; the preprocessing includes removing normal data, retaining abnormal data and converting the abnormal data into a unified format and transmitting it to the feature extraction module.

[0062]Step 2: The feature extraction module first judges whether the abnormal data in a unified format is read, if the abnormal data is not read, then continue to read;...

Embodiment 2

[0090] A multi-high-speed rotating equipment operation data analysis system, including

[0091] The data retrieval module is used to retrieve operating data from the database of the multi-high-speed rotating equipment monitoring system;

[0092] The data preprocessing module is used to preprocess the operation data retrieved by the data retrieval module, remove normal data, retain abnormal data and convert it into a unified format;

[0093] The feature extraction module is used to perform feature extraction on abnormal data converted into a unified format to obtain data features;

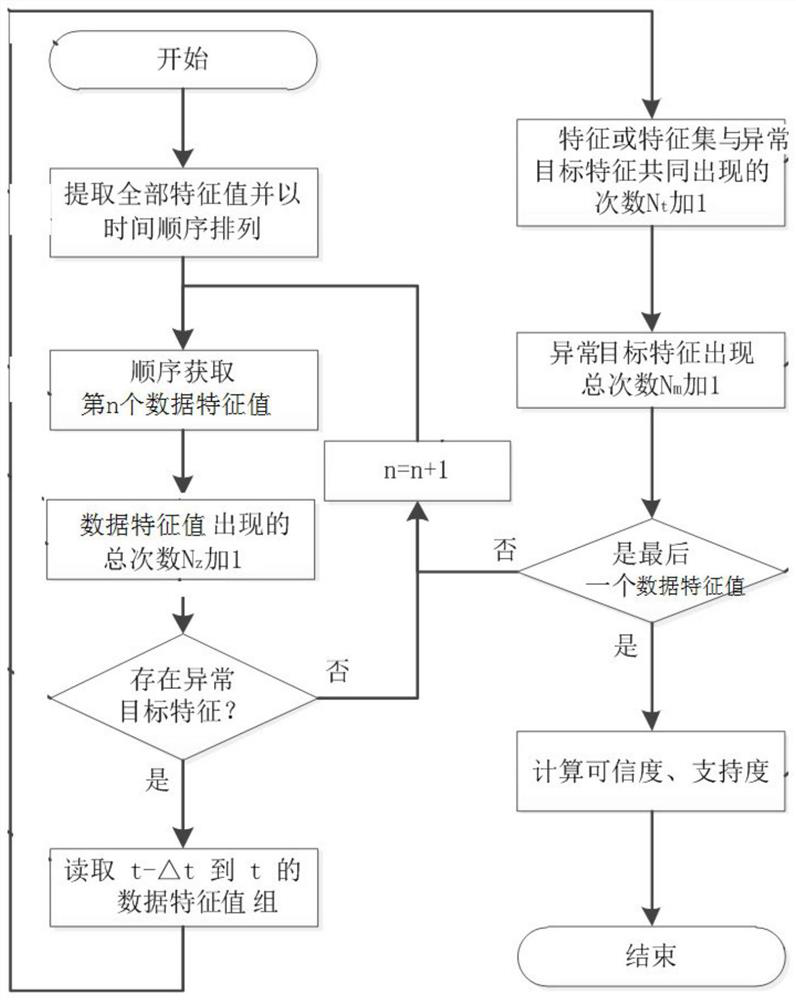

[0094] The correlation analysis module is used to perform correlation analysis on the data features obtained by feature extraction, that is, to calculate the credibility and support of the obtained data features;

[0095] A re-learning algorithm is used to update the data features of the relationship between the credibility and support and the expected value to the fault database;

[0096] The fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com