Anti-rollover device for overhanging I-shaped steel overlapping part

An I-beam, anti-rollover technology, applied in the direction of thin plate connection, rod connection, connection member, etc., can solve the problems of damage or destruction of I-beam, inconvenient welding operation, disadvantageous embedded ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

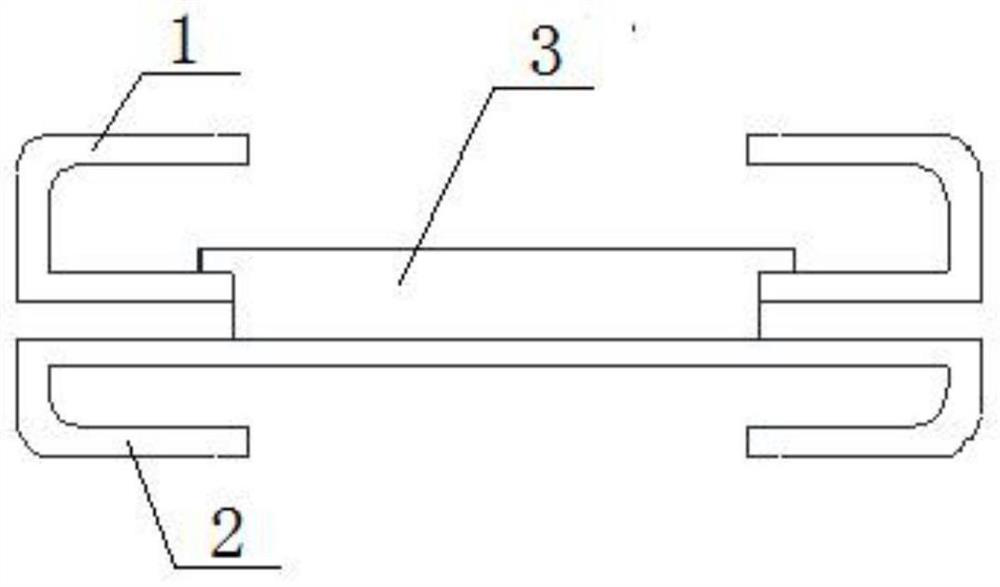

[0013] Refer Figure 1-3 An anti-side flushing of the overlapping portion of the hanging-based type steel, including upper C-shaped members 1 and lower C-shaped members 2, the upper C-shaped member 1 is located above the lower C-shaped member 2, and the top of the lower C-shaped member 2 is fixed The connecting shaft 3 is mounted, the connecting shaft 3 active jacket is attached to the upper C-shaped member 1.

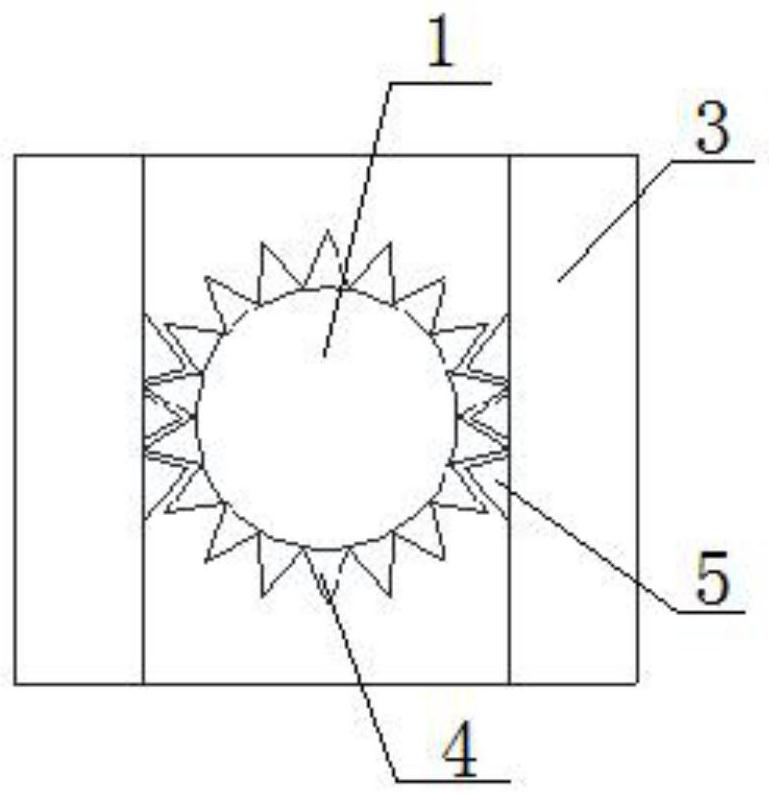

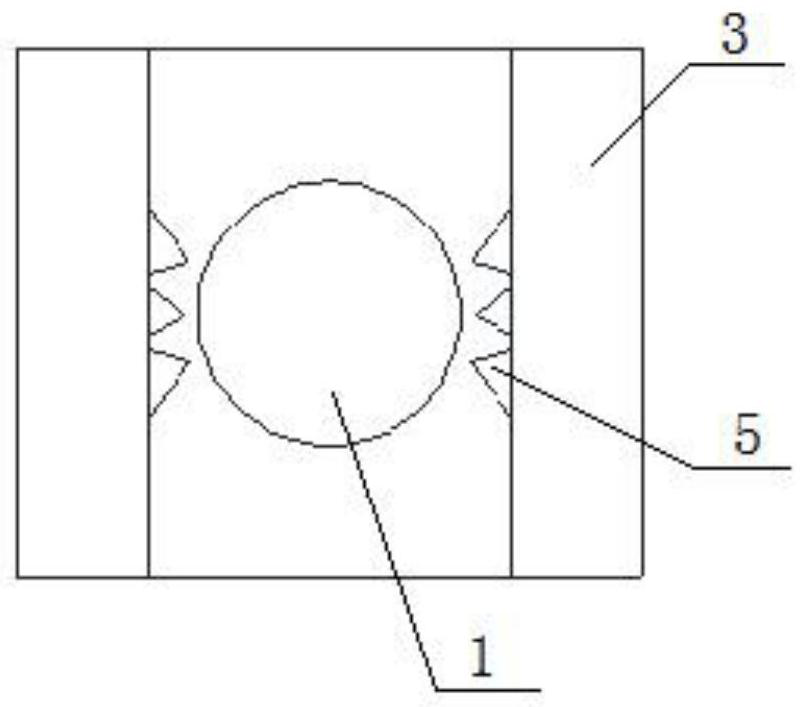

[0014] In the present invention, the intermediate position of the upper C-shaped member 1 fixes a plurality of toothed cards 4, and the inner wall of the connecting shaft 3 is fixedly mounted, and the toothed card 4 and the toothed card are fixed. Slot 5 is adapted.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap