Shale gas productivity prediction method based on multi-scale fault development characteristics

A technology for productivity prediction and development characteristics, applied in earthwork drilling and production, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

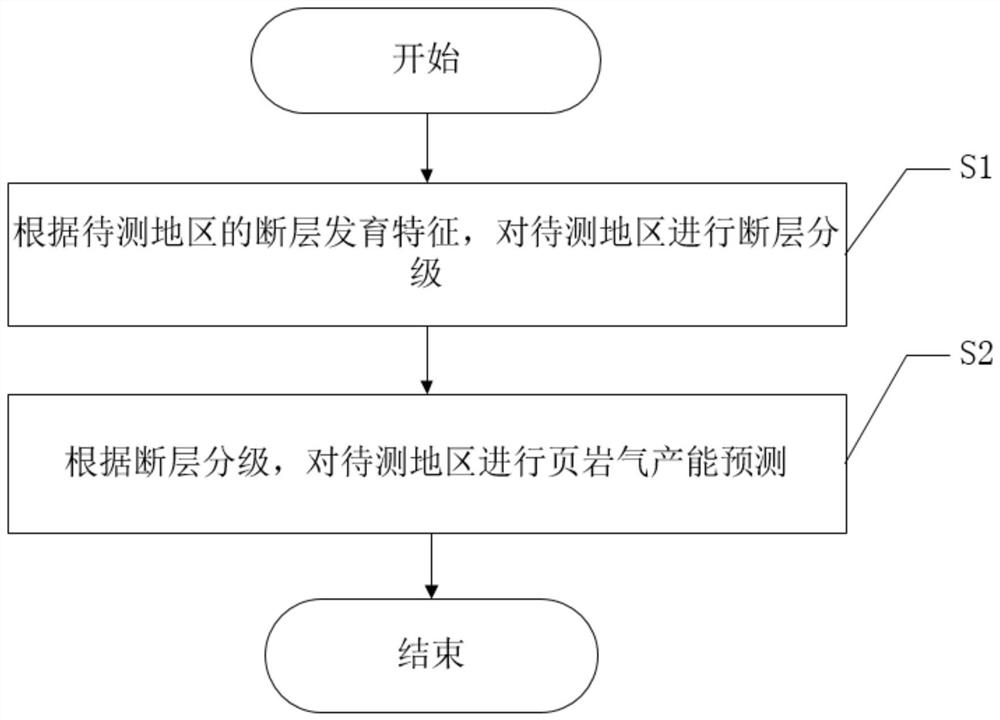

[0030] Such as figure 1 As shown, the present invention provides a shale gas productivity prediction method based on multi-scale fault development characteristics, including the following steps:

[0031] S1: According to the fault development characteristics of the area to be measured, classify the faults in the area to be measured;

[0032] S2: Predict shale gas production capacity in the area to be tested according to fault classification.

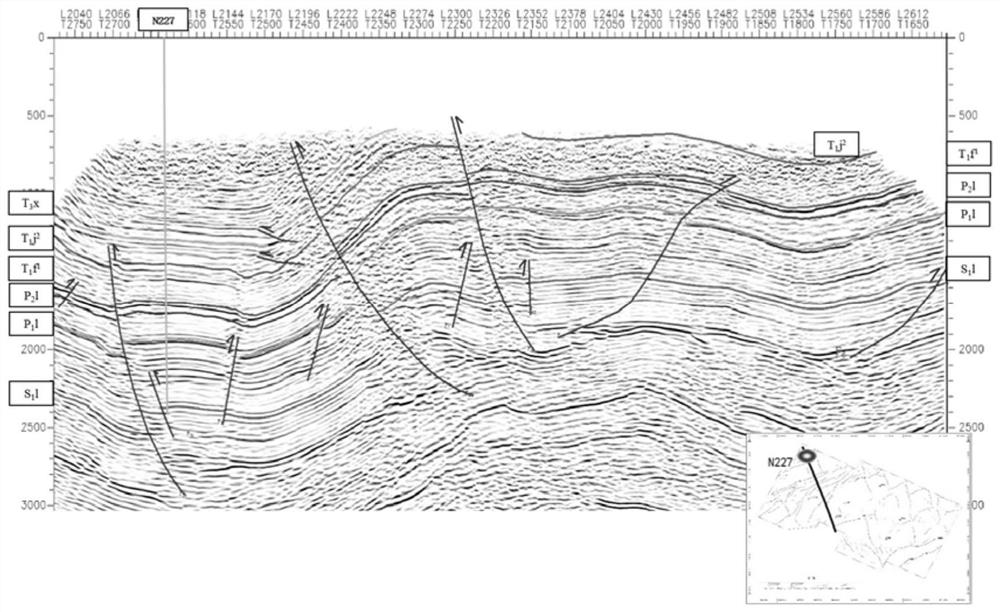

[0033] In the embodiment of the present invention, in step S1, the specific method for classifying the faults in the area to be measured is as follows: taking the fault throw, azimuth, disconnection horizon, extension length, and dip angle of the fault plane as classification indicators, and classifying the faults in the area to be measured ;

[0034] Among them, the area to be measured with a fault distance gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com