Manual and electric switching device and electric actuator

A switching device, hand-operated technology, applied in valve devices, mechanical drive clutches, valve operation/release devices, etc., can solve the problems of not easy operation, injury to operators, inability to automatically switch, etc., and achieve reliable self-locking characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

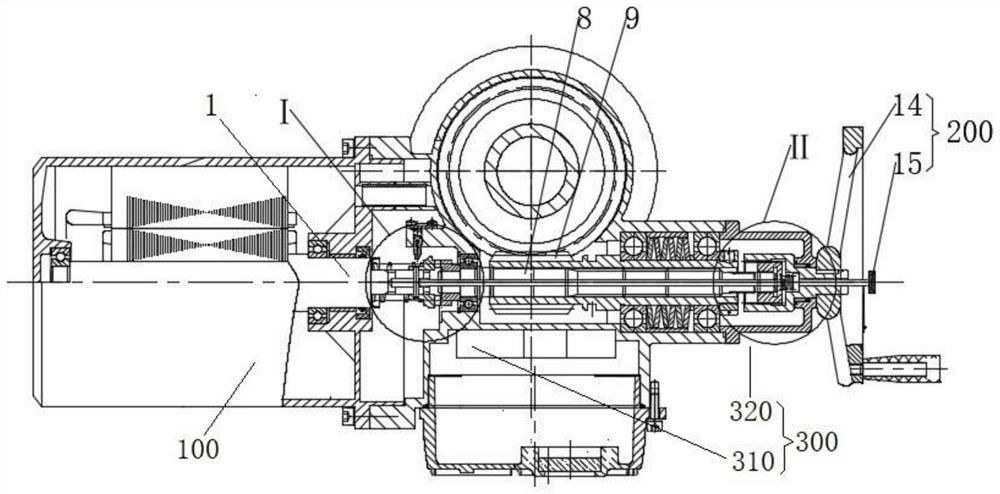

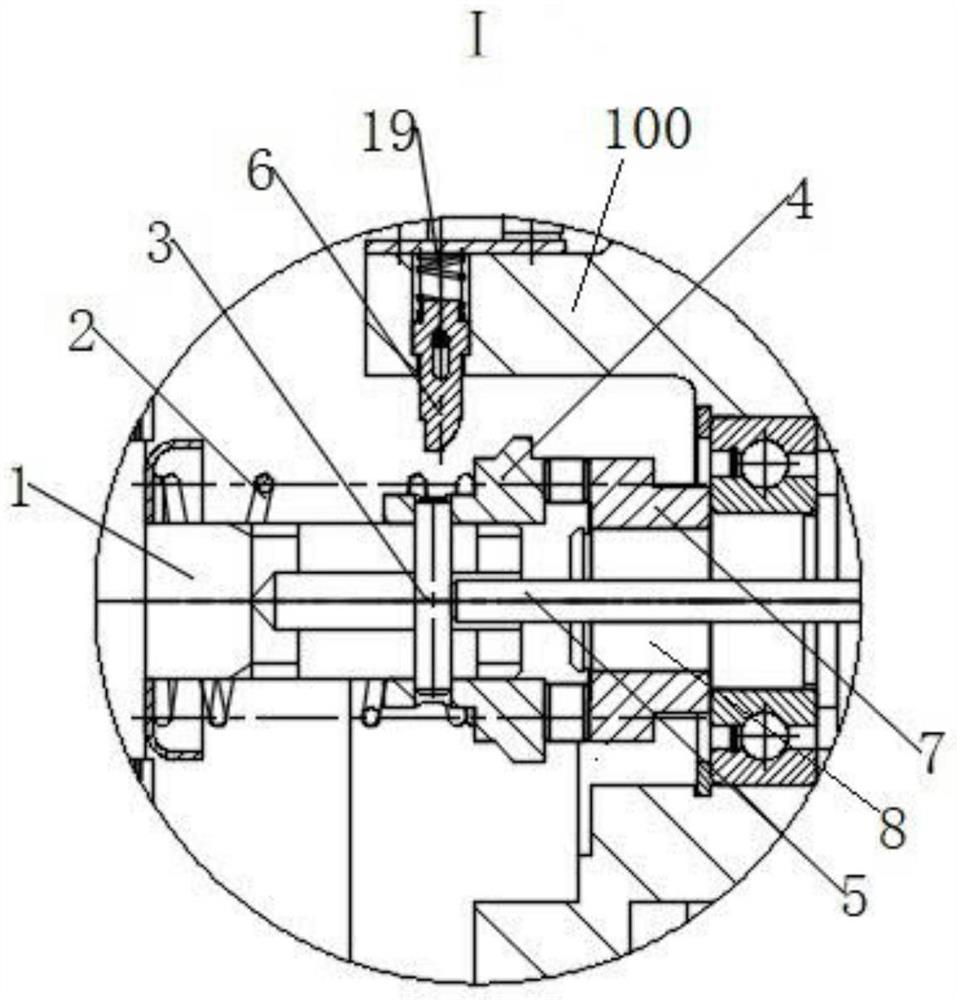

[0036] see figure 1, the present invention provides a manual electric switching device, including a housing 100 , a first motor 1 , a manual drive assembly 200 and a clutch assembly 300 . The clutch assembly 300 is installed in the housing 100 , the first motor 1 is installed at one end of the clutch assembly 300 , and the manual drive assembly 200 is installed at the other end of the clutch assembly 300 . The first motor 1 and the manual drive assembly 200 can be connected with the clutch assembly 300 respectively: when the clutch assembly 300 is connected to the manual drive assembly 200 and disconnected from the first motor 1, the The torque of the manual drive assembly 200 can be transmitted to the clutch assembly 300; when the clutch assembly 300 is connected to the first motor 1 and disconnected from the manual drive assembly 200, the first motor 1 Torque can be transmitted to the clutch assembly 300, and the manual drive assembly 200 is a detachable structure.

[0037...

Embodiment 2

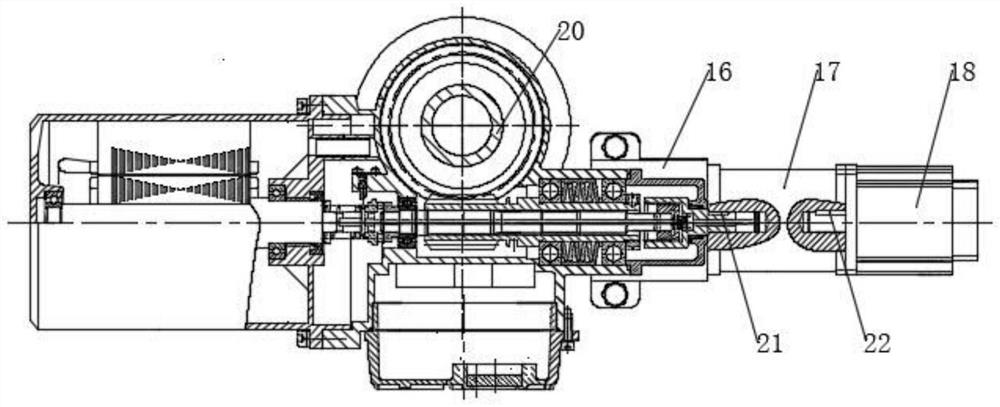

[0054] see figure 2 , this embodiment provides a manual electric switching device. This embodiment is an improvement made on the technical basis of the first embodiment above. key 21 and a second key 22. The fixed frame 16 is installed on the outside of the spline sleeve 11, and the second motor 18 is installed on the inside of the fixed frame 16 corresponding to the outer end of the push rod 13. Between the second motor 18 and the push rod 13 The planetary reducer 17 is installed, the first key 21 is installed between the planetary reducer 17 and the handwheel claw 10, the planetary reducer 17 and the second motor 18 are installed between the Second key 22.

[0055] In this embodiment, the second motor 18 and the planetary reducer 17 can replace the hand wheel 14 . When the device needs to be switched from the electric state to the manual state, the handle 15 is first pressed to move the push rod 13 into the device, and then the planetary reducer 17 and the second motor ...

Embodiment 3

[0058] read on Figure 1 to Figure 4 , this embodiment also provides an electric actuator, including the manual electric switching device described in Embodiment 1 and Embodiment 2 and an output component 20 , the output component 20 is engaged with the worm 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com