Mold temperature control system

A technology of mold temperature and control system, applied in manufacturing tools, configuration of indicating equipment/measuring equipment, metal processing equipment, etc. /or yield, suppressing setup space and/or cost, achieving the effect of mold temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

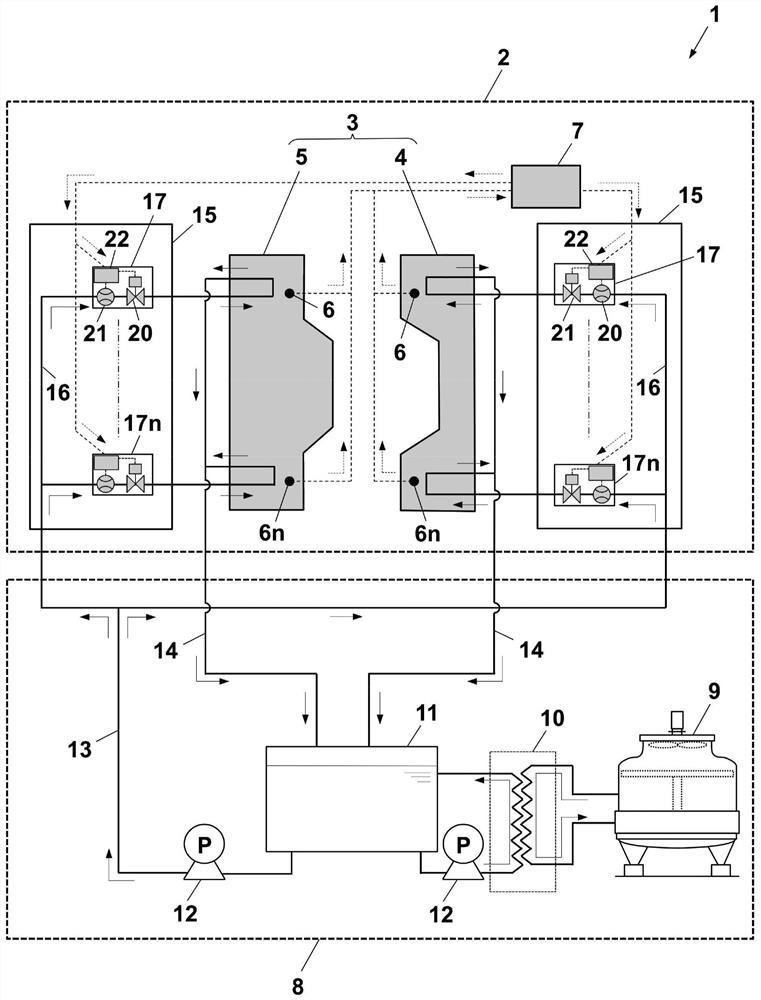

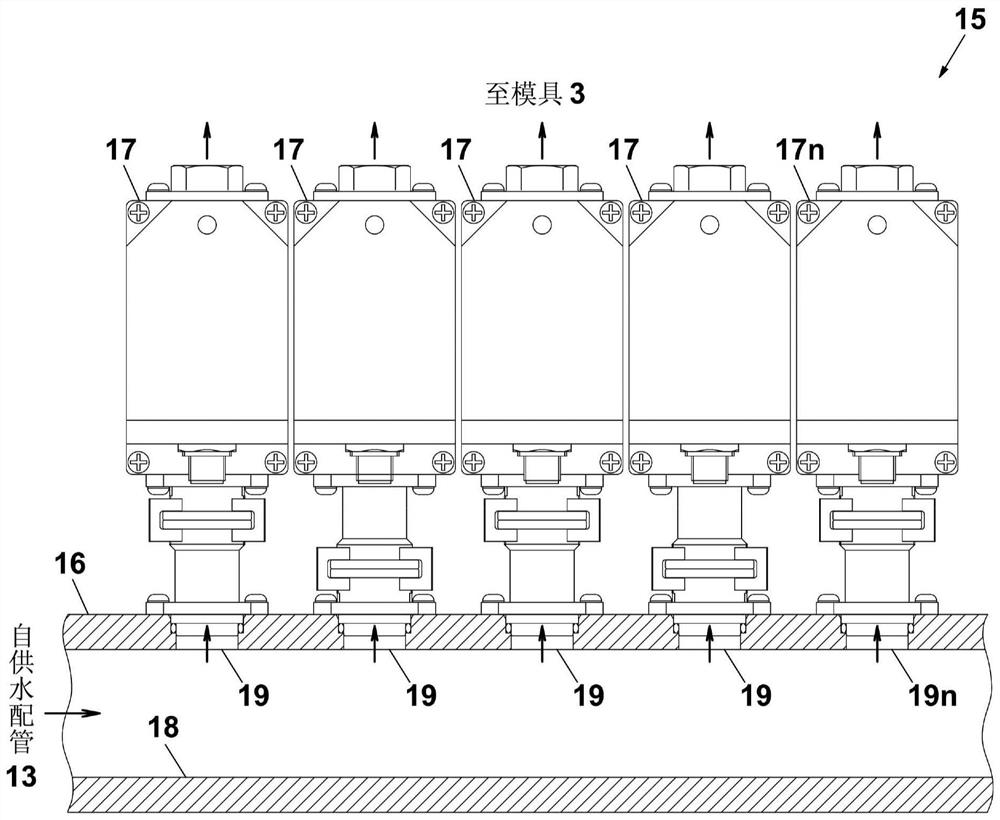

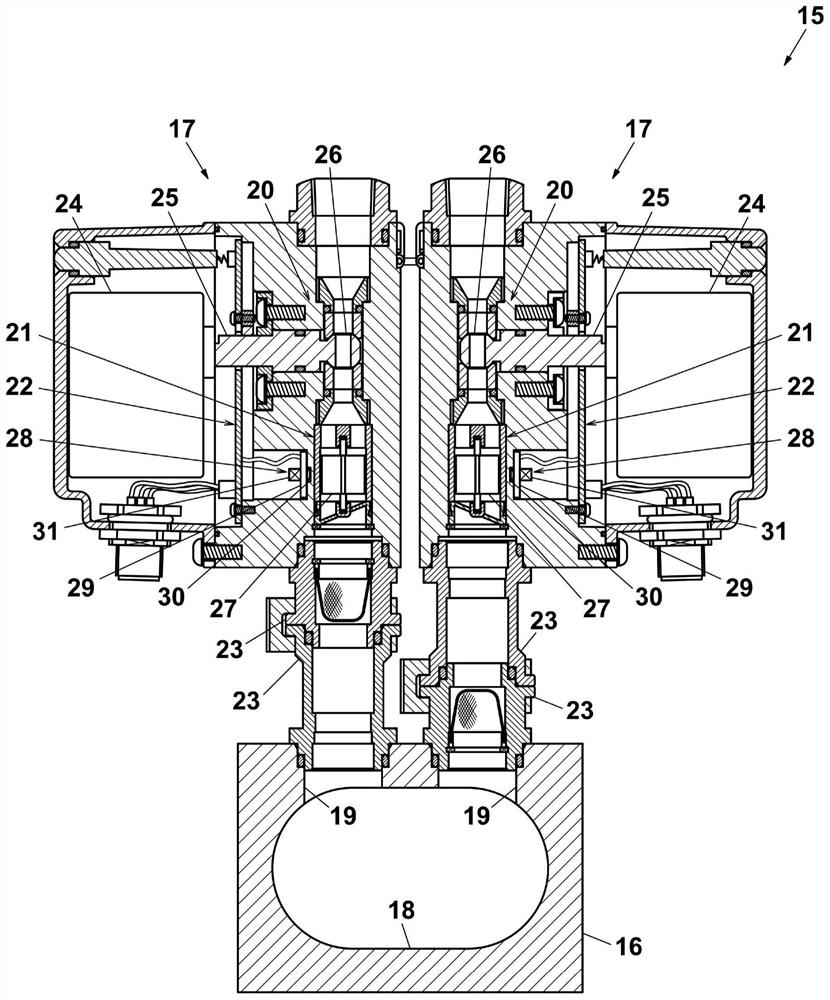

[0038] Such as figure 1 As shown, the mold temperature control system 1 of this embodiment controls the temperature of the mold 3 by changing the flow rate of cooling water controlled at a certain flow rate during production in the die-casting machine 2 that produces (casts) aluminum die-casting products. system. The mold 3 constitutes a part of the die casting machine 2 and includes a fixed mold 4 provided in an injection device and a movable mold 5 provided in a mold clamping device.

[0039] Temperature sensors 6 (˜6n) including thermocouples or resistance temperature sensors are attached to various parts of the mold 3 (fixed mold 4 and movable mold 5 ). The temperature sensor 6 detects the highest temperature, the lowest temperature, the average temperature and the current temperature of the mold 3 in the production cycle in real time. The detected temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com