Automatic boxing equipment for packaging groups with linings

A technology of automatic packing and packing group, applied in the directions of packing, packing bottles, packing protection, etc., can solve the problems of low efficiency of manual completion and difficult to meet the needs of automatic filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

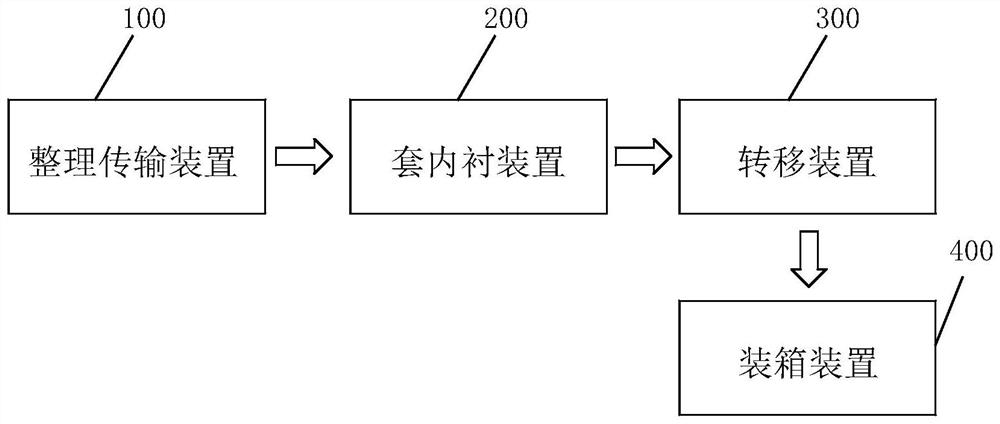

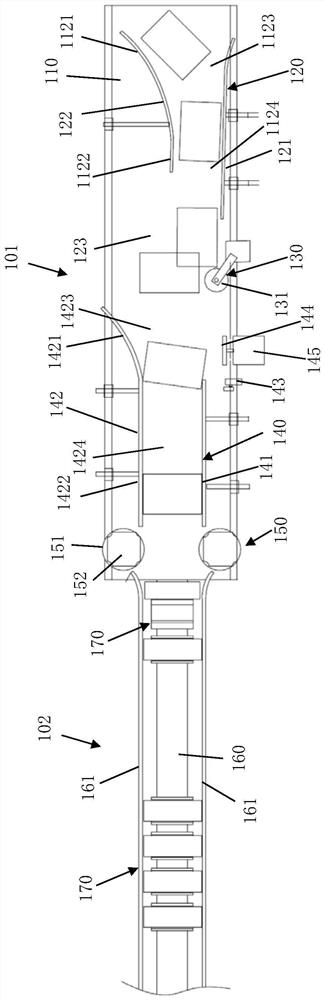

[0026] like figure 1 As shown, the automatic boxing equipment of the lined packaging group of the present invention includes a sorting and conveying device 100 , a sleeve lining device 200 , a transfer device 300 and a boxing device 400 in sequence according to the boxing process.

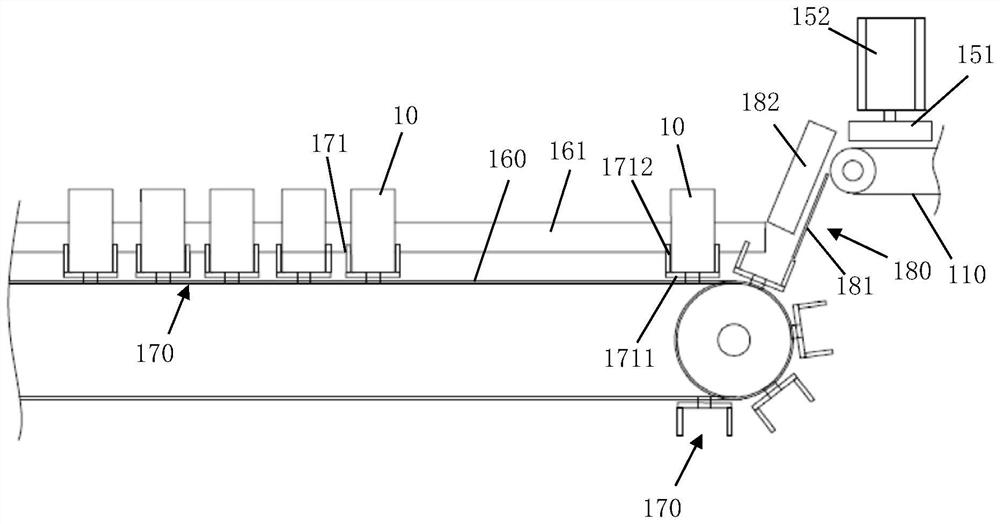

[0027] Wherein, the sorting and conveying device 100 is used for grouping and sorting the finished inner packaging products into a neat arrangement at equal intervals in a sideways posture. What needs to be explained here is that the inner packaging finished product is divided into flat posture, side posture and erect posture on the supporting surface. Standing posture refers to the posture where the surface where the length side and thickness side of the inner packaging product is located is in contact with the support surface, and the erect posture refers to the posture where the surface where the width side and thickness side of the inner packaging product is located is in contact with the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com