Mechanical support within molded chip package

A packaging and chip mounting technology, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., to solve problems such as contact space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

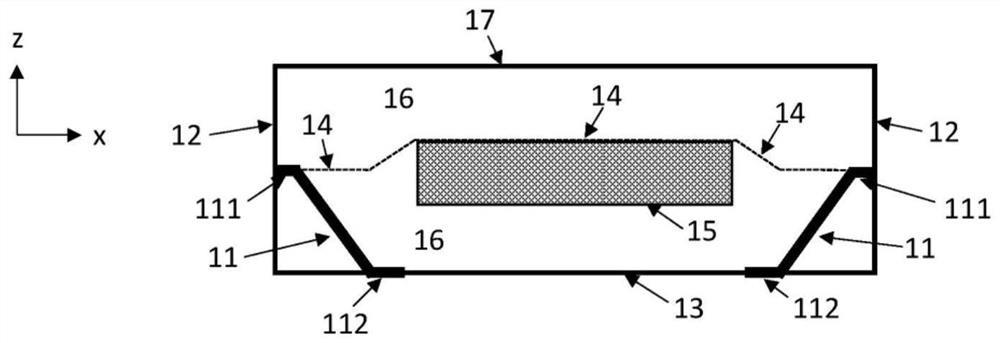

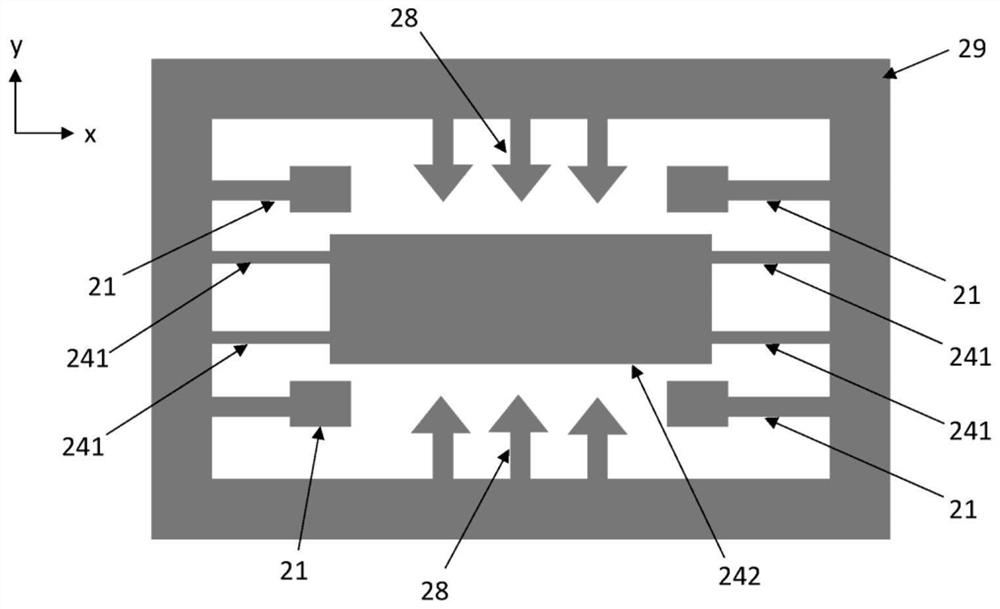

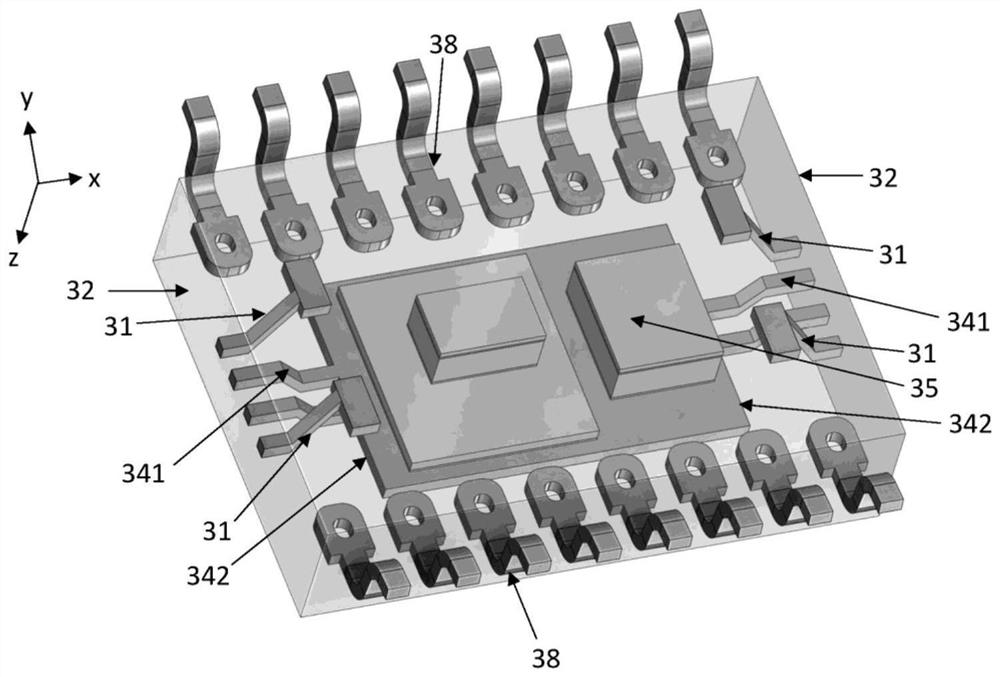

[0018] The present disclosure describes an electronic component that includes a package body that includes a set of side walls and a bottom wall that shares a common edge with each of the set of side walls. The bottom and side walls define an enclosed interior space, and each side and bottom wall have an inner surface and an outer surface. One or more chip mounting elements extend from the inner surface of the at least one side wall into the enclosed interior space. At least one electronic chip is attached to the one or more chip mounting elements within the enclosed interior space. The electronic component also includes one or more stiffening elements extending from the inner surface of one of the side walls to the outer surface of the bottom wall within the enclosed interior space. The one or more stiffening elements are separated from the one or more chip mounting elements within the enclosed interior space.

[0019] The chip mounting elements may include support elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com