Conveyor Mechanism for Dental Floss Packing Machine with Counting and Automatic Compensation Functions

A conveying mechanism and automatic compensation technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem of not being able to meet bagging requirements, and achieve the effect of satisfying bagging requirements, ensuring accuracy, and improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following in conjunction with the accompanying drawings, a preferred embodiment of the present invention will be described in detail.

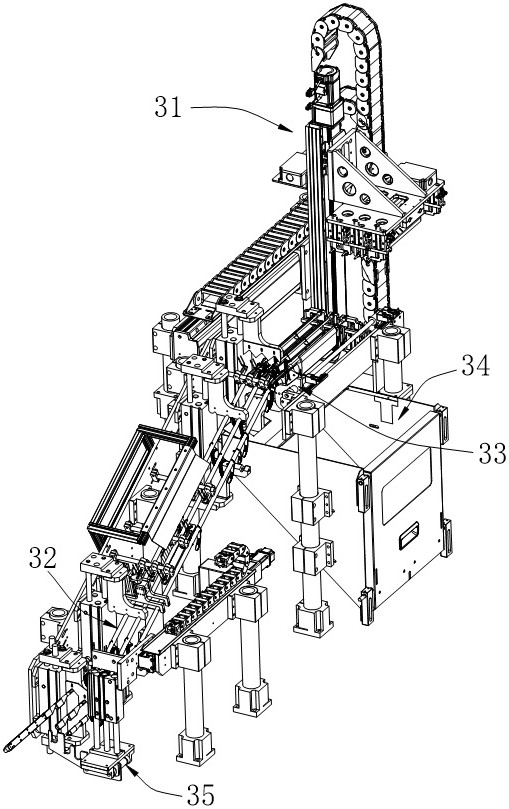

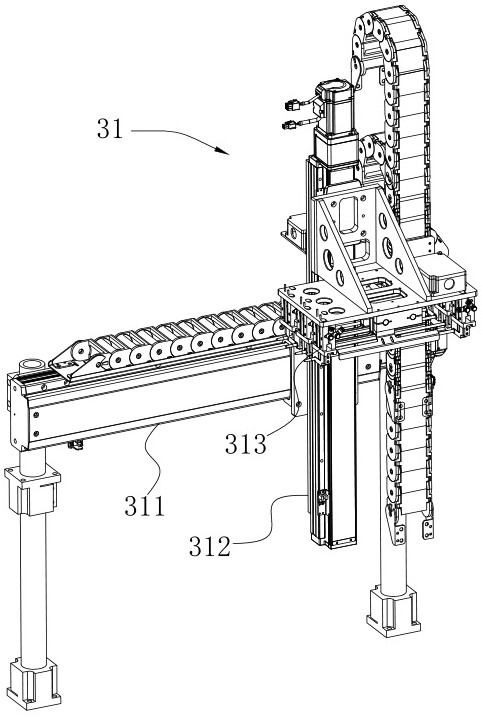

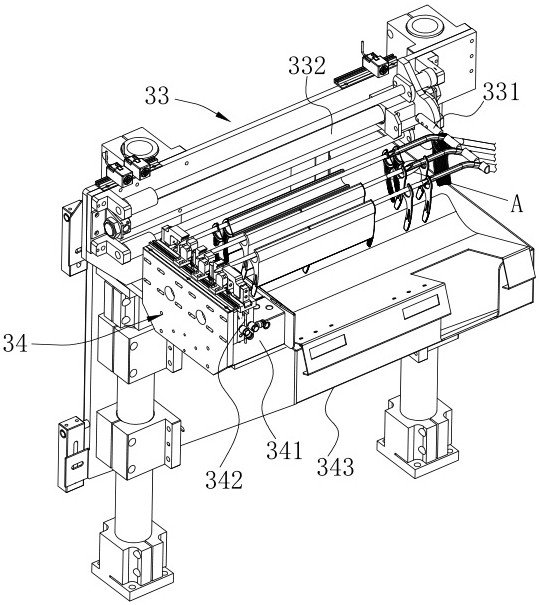

[0045] See Figure 1 , the present invention provides a dental packing machine with counting and automatic compensation function, a transitional conveying mechanism between the feeding mechanism of the dental packing machine and the bagging mechanism, capable of picking up the dental floss on the feeding mechanism and transporting it to the bagging mechanism. Dental packing machine with counting and automatic compensation function with conveyor mechanism includes: handling mechanism 31, fixed number conveying mechanism 32, first pushing mechanism 33, carrier chopsticks recycling mechanism 34 and second pushing mechanism 35.

[0046] See Figure 1 and Figure 5 , the fixed number of conveying mechanism 32 is provided on the side of the handling mechanism 31, the fixed number of conveying mechanism 32 includes a fixed bracket, three parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com