Construction method of underwater tubular pile type foundation and underwater tubular pile type foundation

A construction method and pipe pile technology are applied to the construction of underwater pipe pile foundations and the field of underwater pipe pile foundations, which can solve the problems of weak enhancement of the bearing capacity of pipe pile foundations, and achieve the enhancement of horizontal resistance and vertical The effect of bearing capacity, improving the ability to resist horizontal displacement, and reducing the risk of tilting to one side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

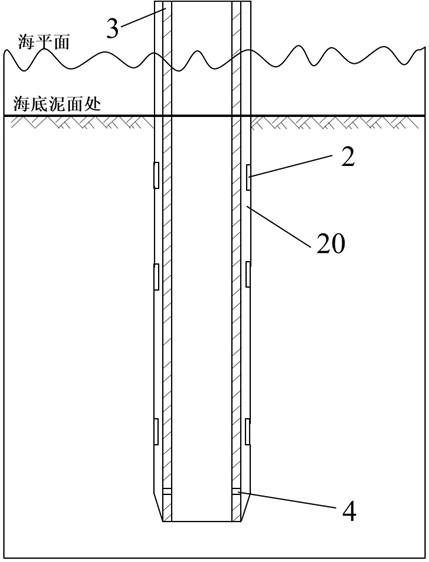

[0041] Such as Figure 1 to Figure 6 As shown, this embodiment provides a construction method for underwater tubular pile foundations, which is suitable for constructing tubular pile foundations in rivers, rivers, lakes, seas and other water bodies, including the following steps:

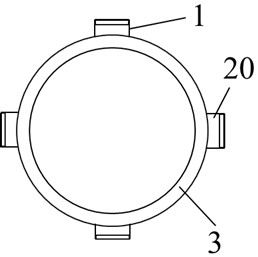

[0042] A construction interlayer 20 is arranged axially on the side wall of the pipe pile body 3 , and four construction interlayers 20 are arranged at intervals along the circumference of the pipe pile body 3 . On the side of the construction interlayer 20 away from the inner cavity of the pipe pile body 3, a plurality of construction openings 17 are arranged in the axial direction, and the construction openings 17 are covered by the high-strength plastic plate 2 as a blocking plate. In this embodiment, at first, holes are spaced along the length direction on the web of the channel steel 1 as the construction opening 17, and the high-strength plastic plate 2 is fixed on the inside of the rectangula...

Embodiment 2

[0051] This embodiment provides an underwater pipe pile foundation, which is constructed by applying the construction method of the underwater pipe pile foundation described in Embodiment 1.

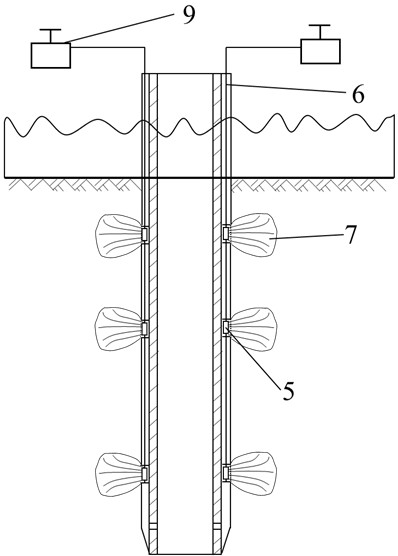

[0052] The bottom of the underwater pipe pile foundation extends into the soil body, including: pipe pile body and soil cavity. The soil cavity is formed in the soil around the pipe pile body, the soil cavity is filled with a cement structure, and the cement structure is connected to the pipe pile body. It also includes a plurality of pile-side grout veins extending divergently from the soil cavity toward a direction away from the pipe pile body, and the pile-side grout veins are integrally connected with the cement structure. By extending the side slurry veins from the cement structure, the resistance of the overall movement of the cement structure is increased, the settlement of the cement structure is prevented, the cement structure can be stably connected around the pipe pile body, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com