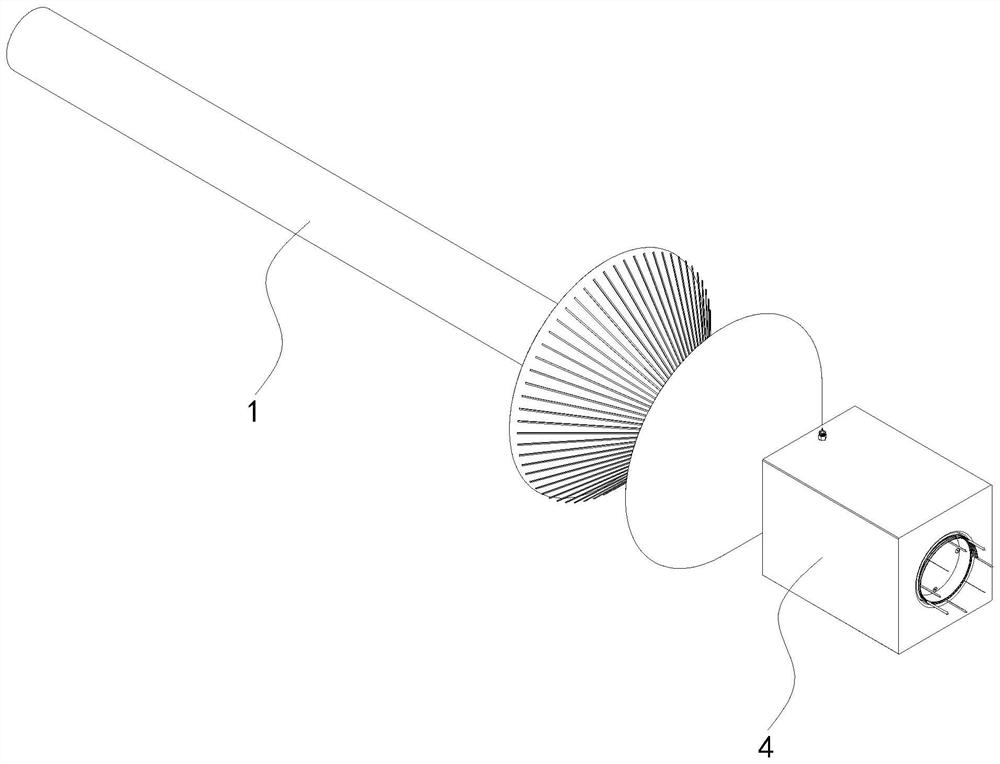

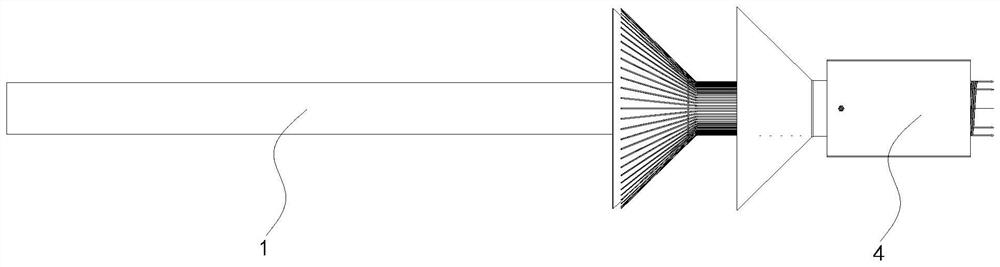

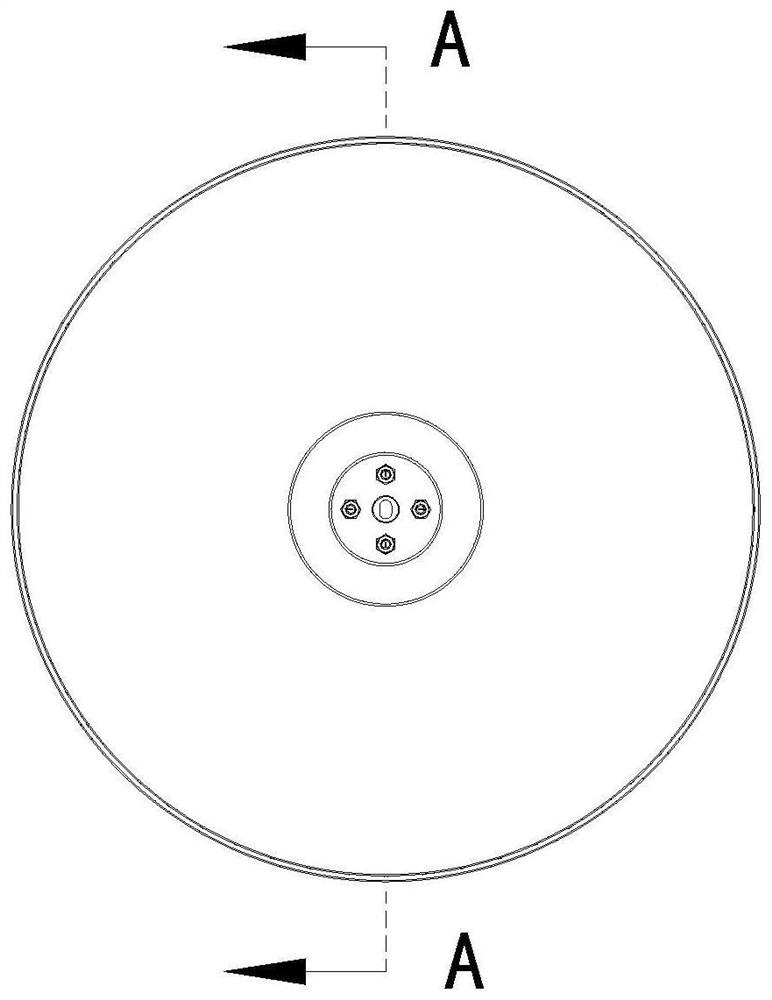

Composite material profile production equipment and system thereof

A technology for composite materials and production equipment, which is applied in the field of composite material profile production equipment and its systems, can solve problems such as uneven distribution of resin, impervious resin infiltration, poor product molding, etc., to achieve uniform distribution, appropriate amount of resin and filler, Good appearance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to describe in detail the possible application scenarios, technical principles, specific solutions that can be implemented, goals and effects that can be achieved, etc., the following will be described in detail in conjunction with the listed specific embodiments and accompanying drawings. The embodiments described herein are only used to illustrate the technical solutions of the present application more clearly, so they are only examples, and cannot be used to limit the protection scope of the present application.

[0062] Reference herein to an "embodiment" means that a particular feature, structure, or characteristic described in connection with the embodiment can be included in at least one embodiment of the present application. The word "embodiment" appearing in various positions in the specification does not necessarily refer to the same embodiment, nor does it specifically limit its independence or relationship with other embodiments. In principle, in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap