LED lamp bead manufactured through support and manufacturing method of LED lamp bead

A technology of LED lamp bead and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve the problems of small-sized lamp beads, short circuit between soldering feet and tin, easy short circuit with tin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Production of punching dies

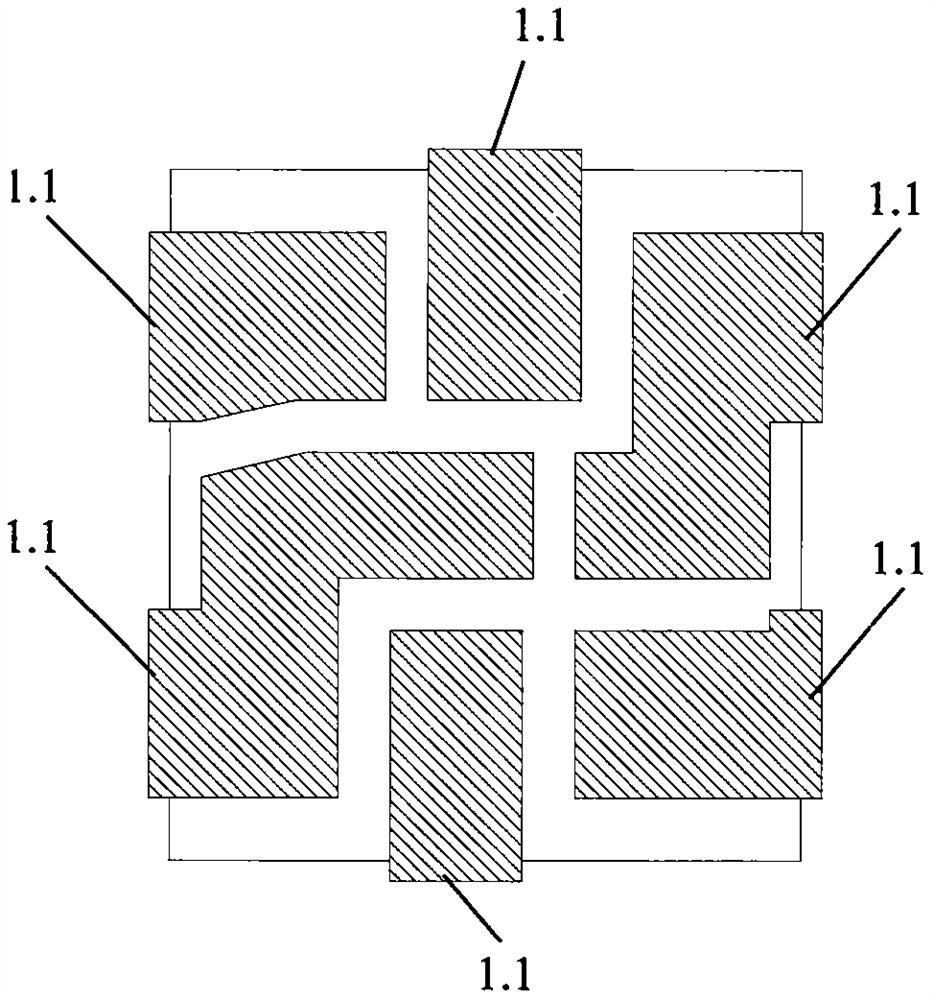

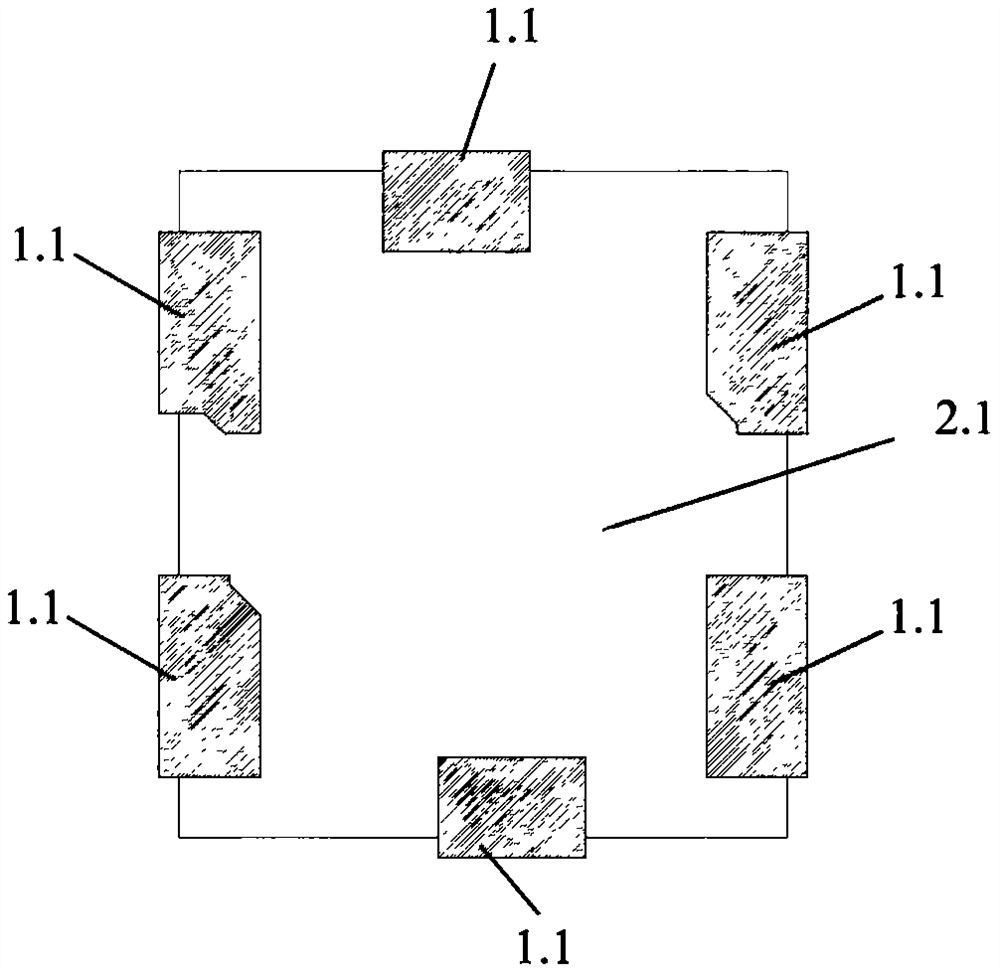

[0028] Design and manufacture a 2835LED bracket with 6 feet, a 2.8mmx3.5mm cuboid bracket, design a soldering leg 1.1 on the two sides with a width of 2.8mm, and design two soldering legs 1.1 on each of the other two sides, a total of 6 soldering legs Feet 1.1.

[0029] 2. The prototype of punching bracket circuit

[0030] The 0.20mm copper strip is prepared, and the 0.20mm copper strip 1.1 is punched into a bracket circuit prototype with a punching die, and then electroplated silver on the bracket circuit prototype, so that the surface of the copper strip is plated with a layer of silver.

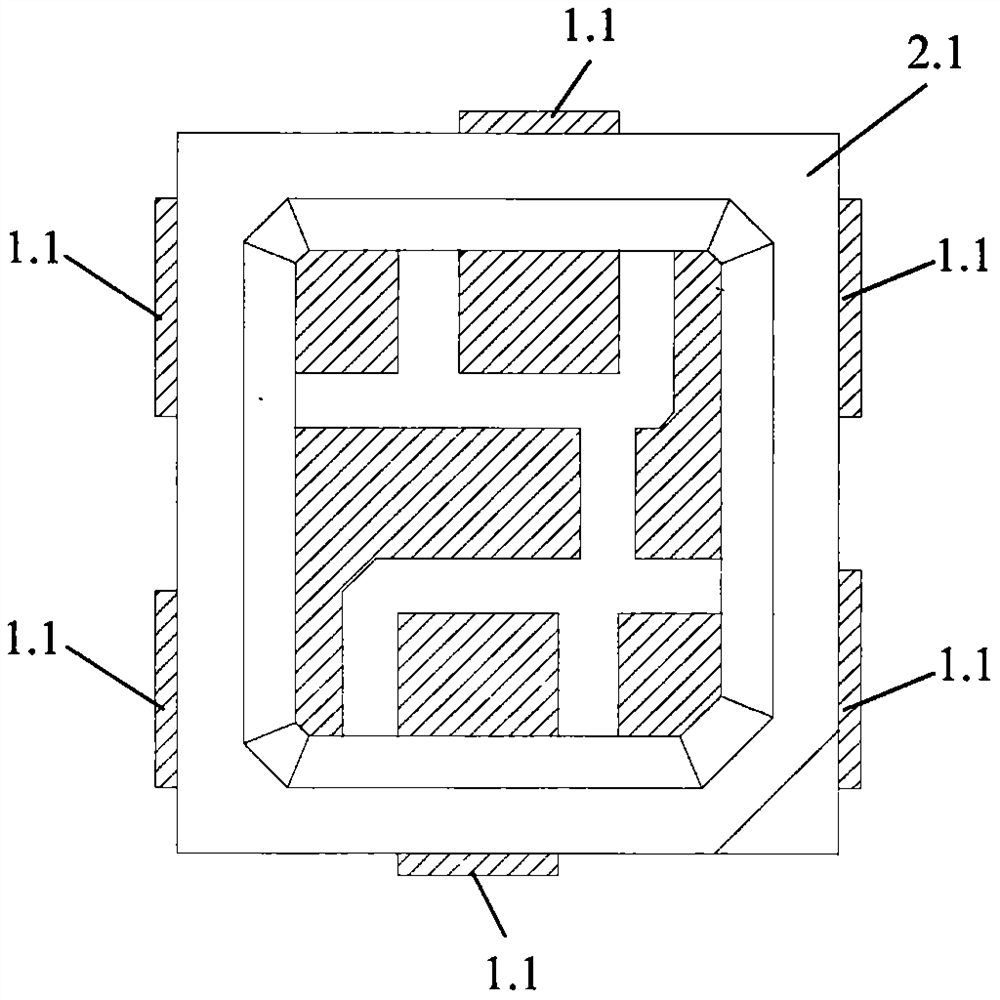

[0031] 3. Production of PPA resin

[0032] Inject the PPA resin 2.1 on the copper strip with an injection mold on the injection molding machine to form a plurality of bracket cups, and embed the copper prototype circuit in the PPA resin.

[0033] 4. Die-cut the bracket to make 6 welding legs

[0034] Die-cutting is used to make a continuous brack...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap