Storage battery multi-sealing structure capable of preventing acid leakage

A technology of multiple seals and storage batteries, applied in the direction of lead-acid batteries, lead-acid battery construction, sealing materials, etc., can solve the problems of battery acid leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

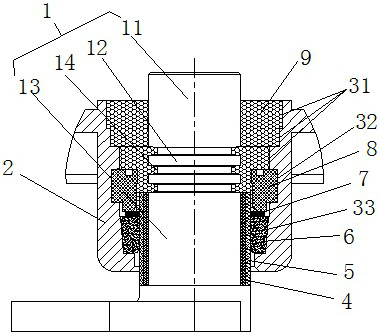

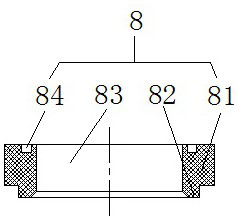

[0030] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a multiple sealing structure of a storage battery for preventing acid climbing and acid leakage includes a pole 1, a hot-melt adhesive layer 4, a heat shrinkable sleeve 5, and a battery cover 2. The battery cover 2 is provided with a pole hole, so The pole 1 is located in the pole hole on the battery cover 2 , the bottom of the pole 1 is wrapped with a hot melt adhesive layer 4 and a heat shrinkable sleeve 5 , and the pole hole is filled with a sealant 9 .

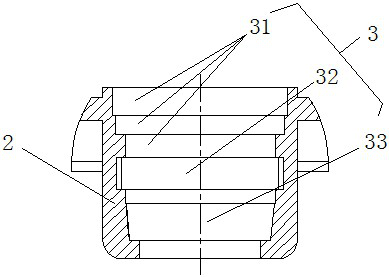

[0031] Such as figure 2 As shown, the pole hole on the battery cover 2 is designed as a special-shaped hole 3, and the pole 1 is located at the center of the special-shaped hole. The special-shaped hole is composed of a stepped hole 31, a threaded hole 32, and a wedge-shaped hole 33. The stepped hole 31 is located on the top of the special-shaped hole, the bottom of the stepped hole 31 is provided with a threaded hole 32 , the inner side of ...

Embodiment 2

[0047] Such as Figure 5 , Figure 6 , figure 2 , image 3 As shown in the figure, a multiple sealing structure of a storage battery for preventing acid climbing and acid leakage includes a pole 1, a hot-melt adhesive layer 4, a heat-shrinkable sleeve 5, and a battery cover 2. The battery cover 2 is provided with a pole hole. The pole 1 is located in the pole hole on the battery cover 2 , the bottom of the pole 1 is wrapped with a hot melt adhesive layer 4 and a heat shrinkable sleeve 5 , and the pole hole is filled with a sealant 9 .

[0048] Such as figure 2 As shown, in the present invention, the pole hole on the battery cover 2 is designed as a special-shaped hole 3, and the pole 1 is located at the center of the special-shaped hole, and the special-shaped hole is composed of a stepped hole 31, a threaded hole 32, and a wedge-shaped hole 33. Formed, the stepped hole 31 is located on the top of the special-shaped hole, the bottom of the stepped hole 31 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com