Telescopic belt type material receiving device used after ink removal of stainless steel plate

A technology of stainless steel plate and material receiving device, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

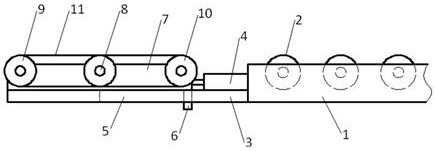

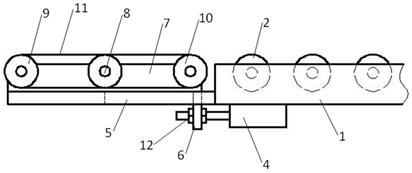

[0028] Such as Figure 1~3 As shown, a telescopic belt-type material receiving device for stainless steel plates after deinking includes a fixed mount 1 arranged on one side of the ink removal tank, and a plurality of conveying rollers 2 for conveying plates are arranged in the fixed mount 1. One side of fixed frame 1 forms extension plate 3, and described extension plate 3 is provided with the slide box 7 that can slide, and described slide box 7 is provided with a plurality of rotating shafts 8 protruding from slide box 7, so The protruding end of the rotating shaft 8 is provided with a pulley, and a conveyor belt 11 is provided on the pulley, and the conveyor belt 11 conveys the stainless steel plate after deinking.

[0029] Both ends of the rotating shaft 8 protrude from the cross slide box 7, and both ends are provided with pulleys, and there are two convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com