Multi-color paint spraying device for vertical wooden handicrafts

A kind of handicraft, vertical technology, applied in the direction of spray device, liquid spray device, spray booth, etc., can solve the problem of unable to carry out color, unable to realize the effect and change of color spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

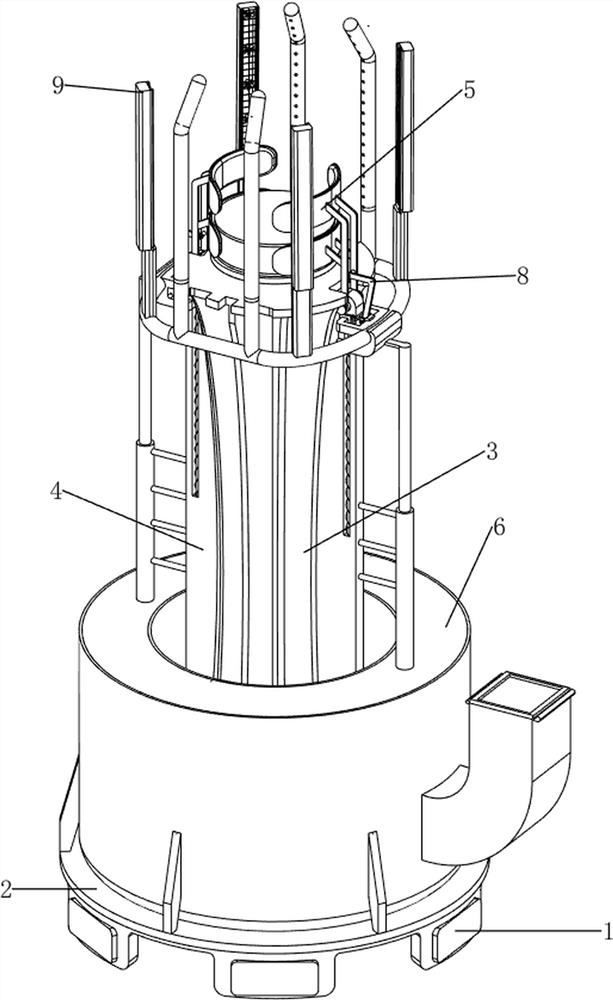

[0035] A vertical multi-color spray painting device for wooden handicrafts, such as Figure 1-7 As shown, it includes a chassis 1, a connecting plate 2, a column 3, a slide rail plate 4, a placement mechanism 5 and a painting mechanism 6. The top of the chassis 1 is provided with a connecting plate 2 by bolts, and the middle of the top of the connecting plate 2 is provided with bolts. The column 3, the left and right sides of the column 3 are welded with slide rail plates 4, the top of the column 3 is provided with a placement mechanism 5, and the placement mechanism 5 is used to place vertical wooden handicrafts. Spray onto vertical wooden crafts.

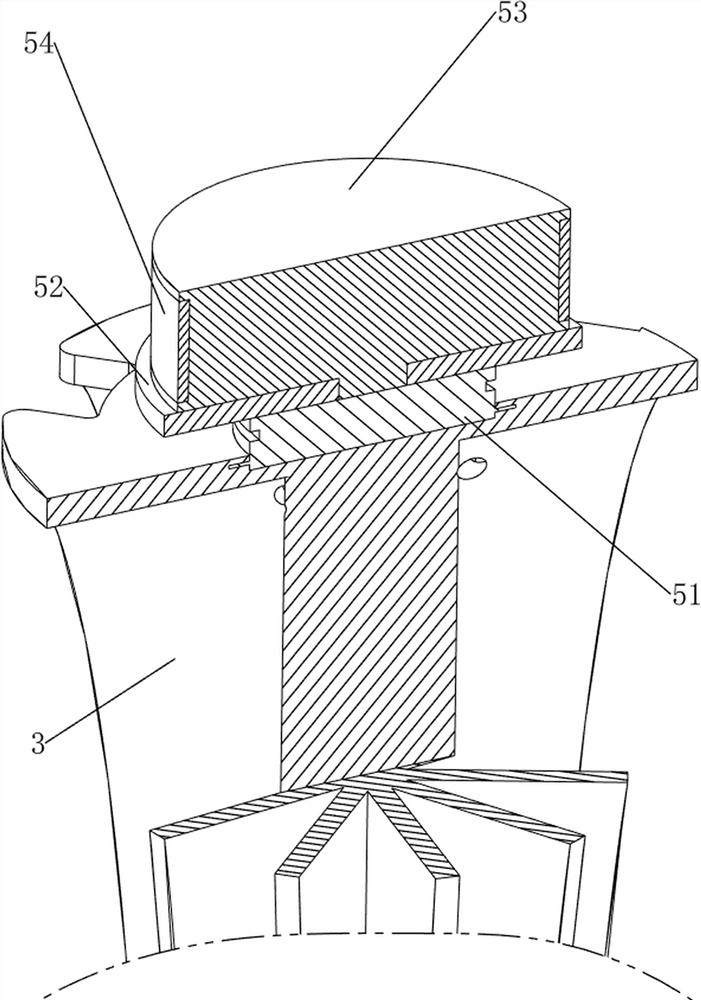

[0036] like image 3 and Figure 4As shown, the placement mechanism 5 includes an embedded block 51, a connecting piece 52, a contact block 53 and a movable enclosure plate 54. The top of the column 3 is rotatably connected with the embedded block 51, and the embedded block 51 can rotate on the top of the column 3. The embedded ...

Embodiment 2

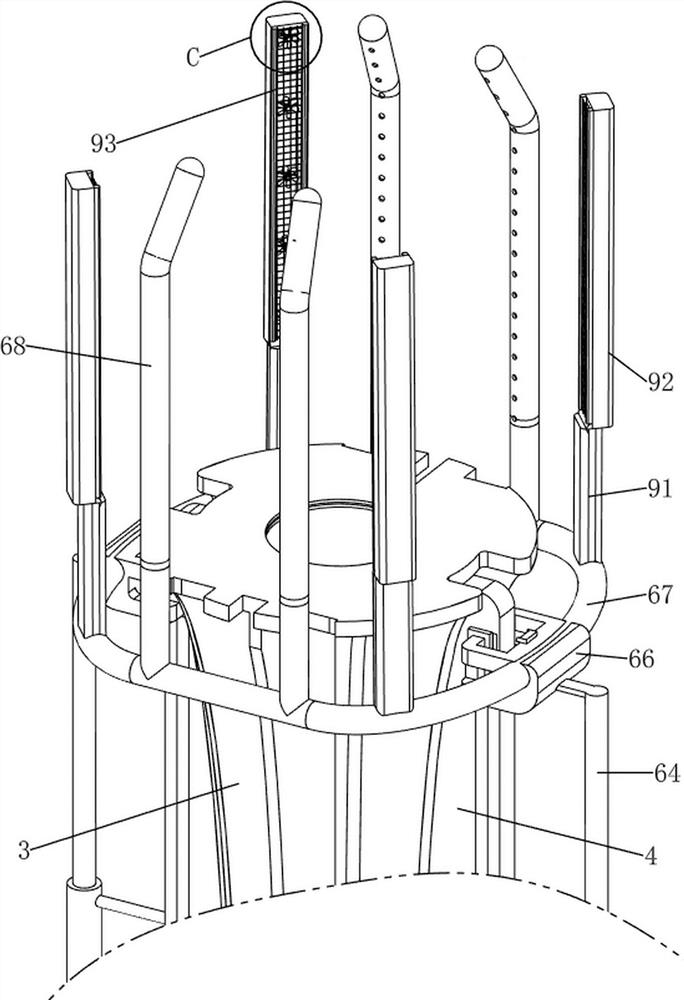

[0040] On the basis of Example 1, as figure 1 , figure 2 , Figure 8 and Figure 9 As shown, it also includes a rotating mechanism 7, which can drive the contact block 53 and the movable enclosure plate 54 to rotate, thereby making the vertical wooden handicraft rotate. The rotating mechanism 7 includes a first fixed plate 71, a first motor 72, an oblique The mold plate 73, the first long rod 74, the second return spring 75, the baffle plate 76 and the pulley assembly 77, the upper rear side of the column 3 is provided with a first fixing plate 71 through bolts, and the left and right sides of the first fixing plate 71 are sliding type A first long rod 74 is connected, and the first fixed plate 71 can guide the first long rod 74. A second return spring 75 is provided between the front side of the first long rod 74 and the first fixed plate 71. The first motor 72 is provided between the rods 74 through bolts, the rear side of the first motor 72 is provided with an inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com