Scraper device and leveling machine

A scraper device and scraping technology, applied in chemical instruments and methods, fixed filter element filters, separation methods, etc., can solve problems such as failure to achieve leveling effect, affecting normal use of the machine, and gaps in the mortar surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

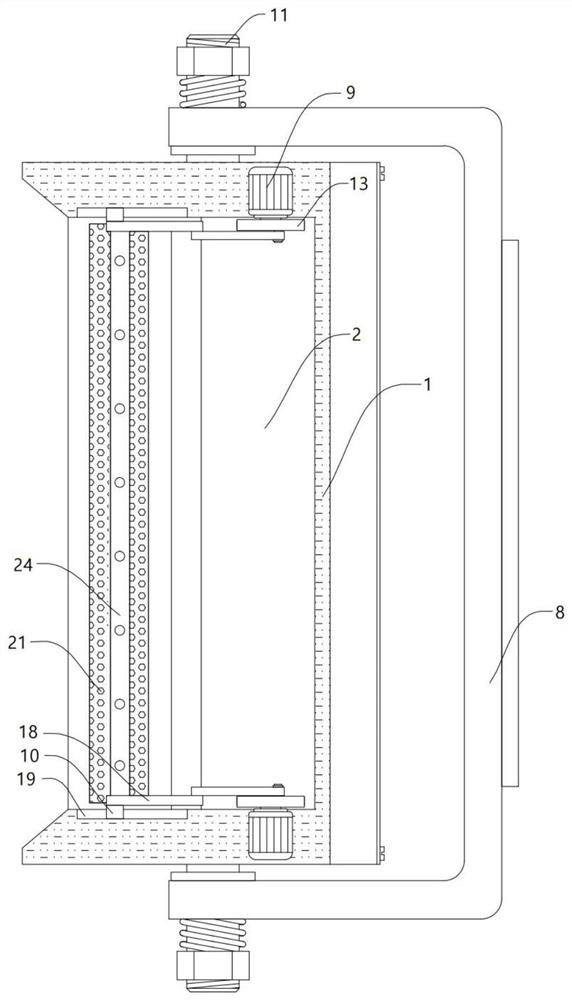

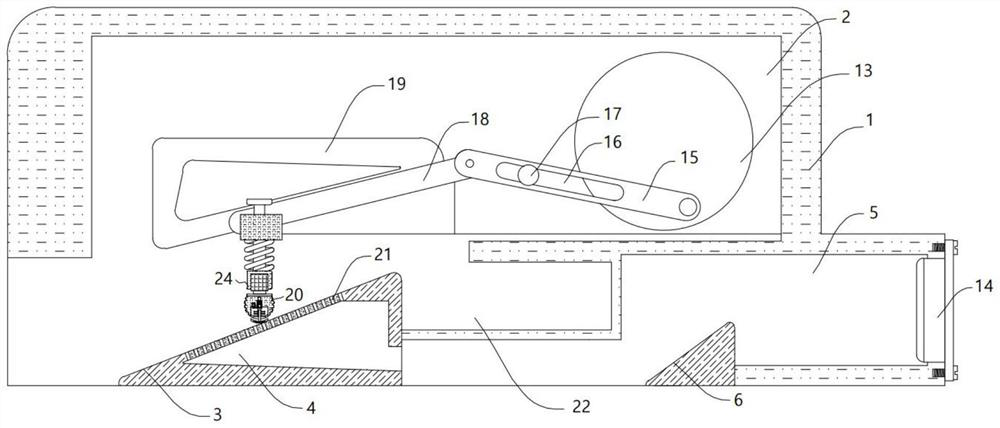

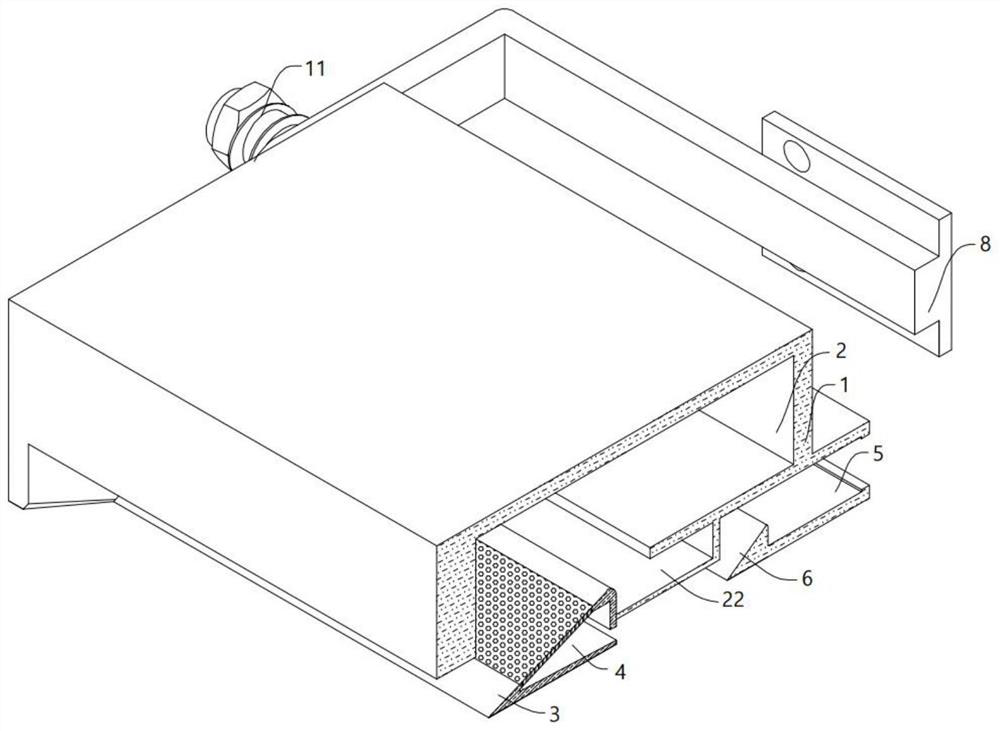

[0029] A scraper device, including a device body 1, a connection cavity 2 is provided in the device body 1, and the left end of the connection cavity 2 extends to the outside of the device body 1, so that when the first scraper block 3 scrapes materials, the material can be normally connected with the second scraper block. A scraper block 3 is in contact with each other, and both ends of the connecting chamber 2 are provided with turntables 13. The two sets of turntables 13 are equal in size and aligned with each other. The turntables 13 are fixedly connected to the output end of the first motor 9, and the first motor 9 is fixedly connected to the connection In the end wall of the cavity 2, the specific model of the first motor 9 is Wuxi Jiebang Motor-60KTYZ-14W, and the opposite faces of the two groups of turntables 13 are provided with a first connecting rod 15 eccentrically, and the first connecting rod 15 is movably connected with the turntable 13. Turn on the first motor 9...

Embodiment 2

[0037] On the basis of Example 1, in order to facilitate the collection of the particles after the second scraping and to dump the collected particles and materials, a material storage chamber 5 is provided in the lower side of the right end of the device body 1 to store materials. The lower end of the chamber 5 is fixedly connected with the second scraper block 6, the filtered material enters the first storage chamber 4 and slides into the surface of the base layer, at this time, the second scraper block 6 will fill the second scraper The excess material will enter into the storage cavity 5 along the second scraping block 6 for the cavity generated after one scraping. The right end of the storage cavity 5 is movable with a sealing cover 14, and the sealing cover 14 moves through six sets of screws. Installed in the device body 1, when it is necessary to clean up the material in the storage chamber 5, at this time, unscrew the screws and remove the sealing cover 14 to dump the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com