Anchor rod and anchor cable drilling and anchoring robot capable of rapidly positioning and replacing drill

A robot and anchor drilling technology, which is applied in the installation of anchor rods, earthwork drilling, drilling equipment, etc., can solve the problems of space limitation of long drilling rigs, short drilling rigs, low efficiency of positioning and installation of anchor rods, etc., and achieve the effect of improving the efficiency of drilling and anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objects and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

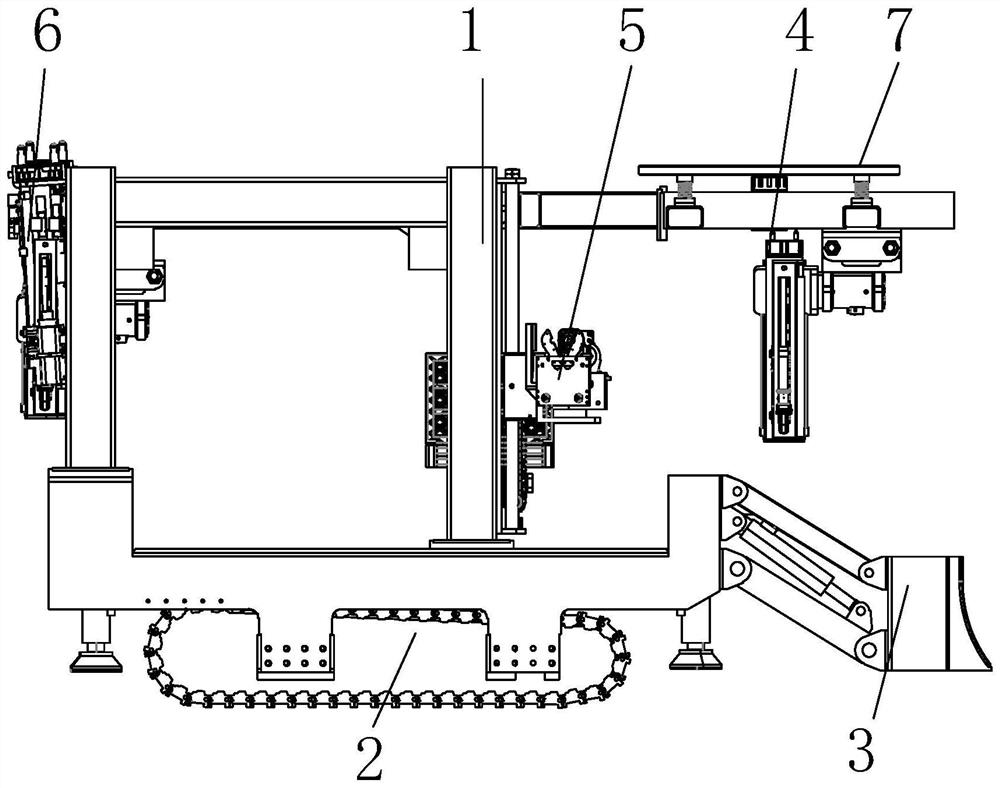

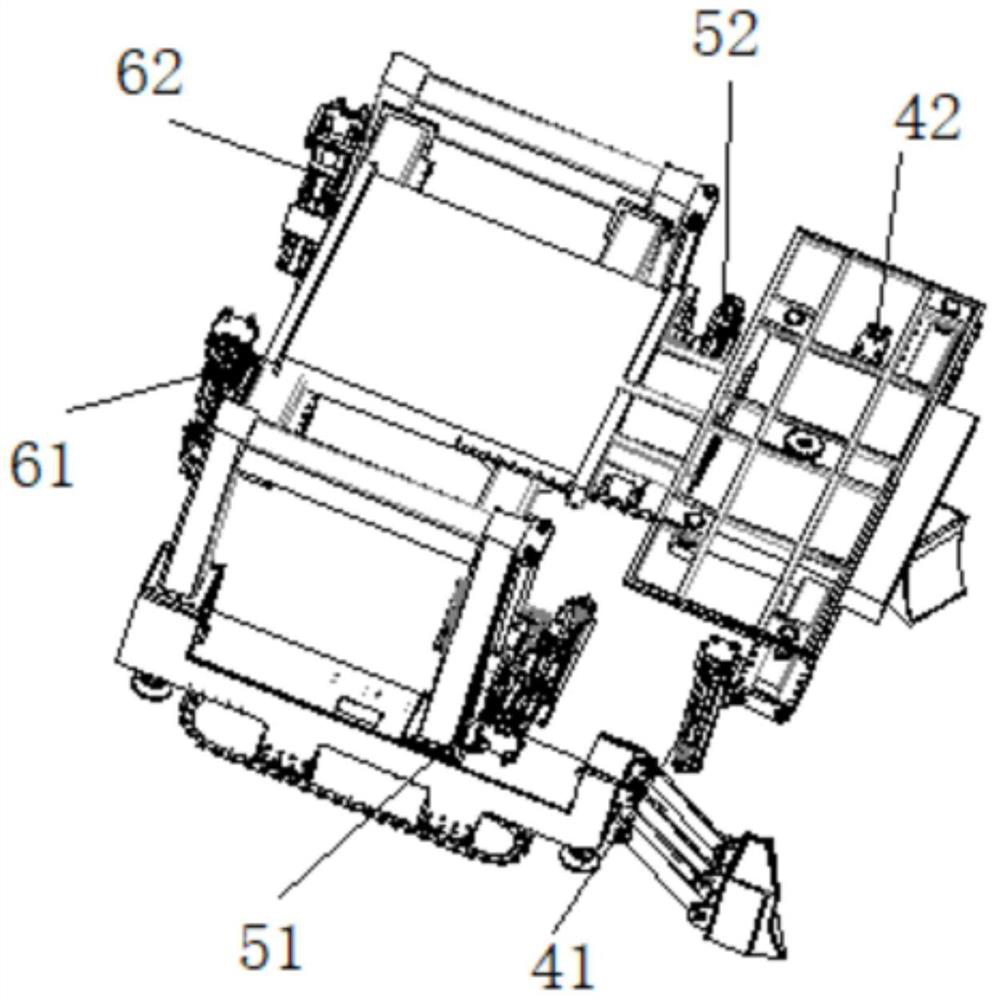

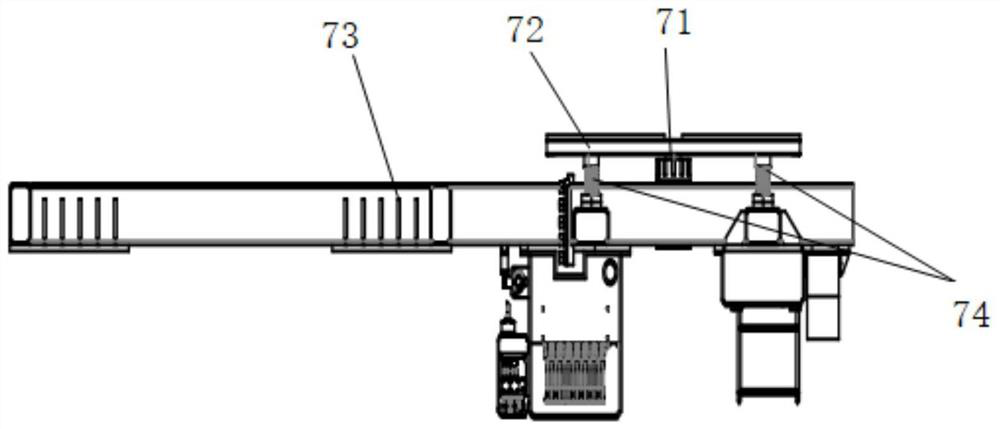

[0022] like Figure 1-Figure 5 As shown in the figure, an anchor rod and cable drilling robot for fast positioning and changing of drills according to an embodiment of the present invention includes a robot frame 1, a crawler walking mechanism 2, an adjustable-angle floating coal clearing mechanism 3, a roof drilling and anchoring mechanism 4, and side rails. Drilling anchor mechanism 5, roof anchor cable drilling anchor mechanism 6, floating support roof mechanism 7; crawler walking mechanism 2 has two groups, which are symmetrically installed on the lower bottom surface of robot frame 1 to provide driving power for the robot; adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com