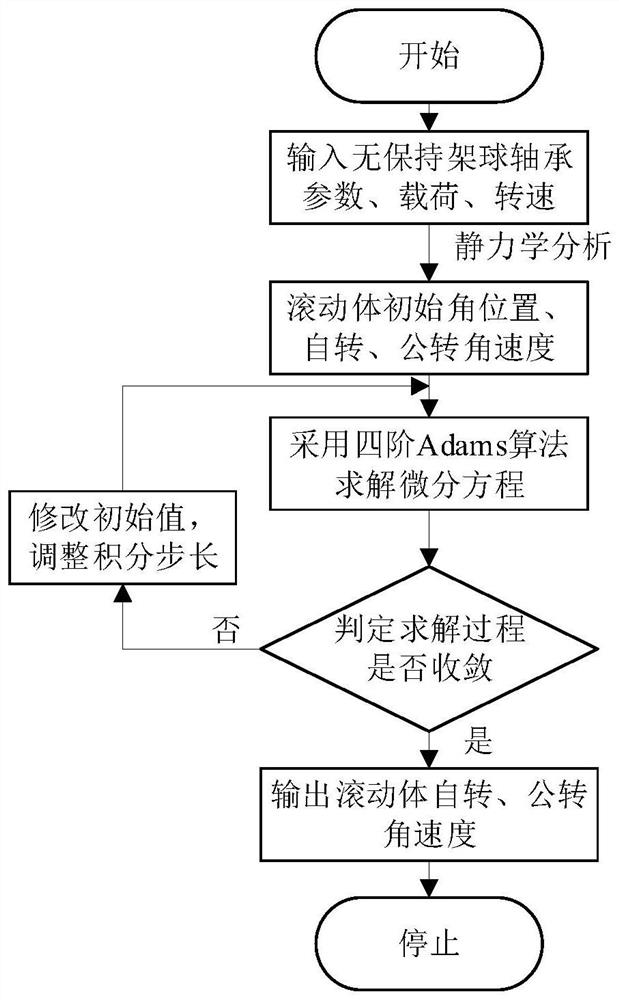

Numerical analysis method for slip of rolling body of retainer-free ball bearing

A numerical analysis and rolling element technology, applied in CAD numerical modeling, electrical digital data processing, instruments, etc., can solve the problems that the sliding speed of rolling elements cannot be obtained through experimental means, and the sliding phenomenon of rolling elements cannot be determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will now be described in further detail.

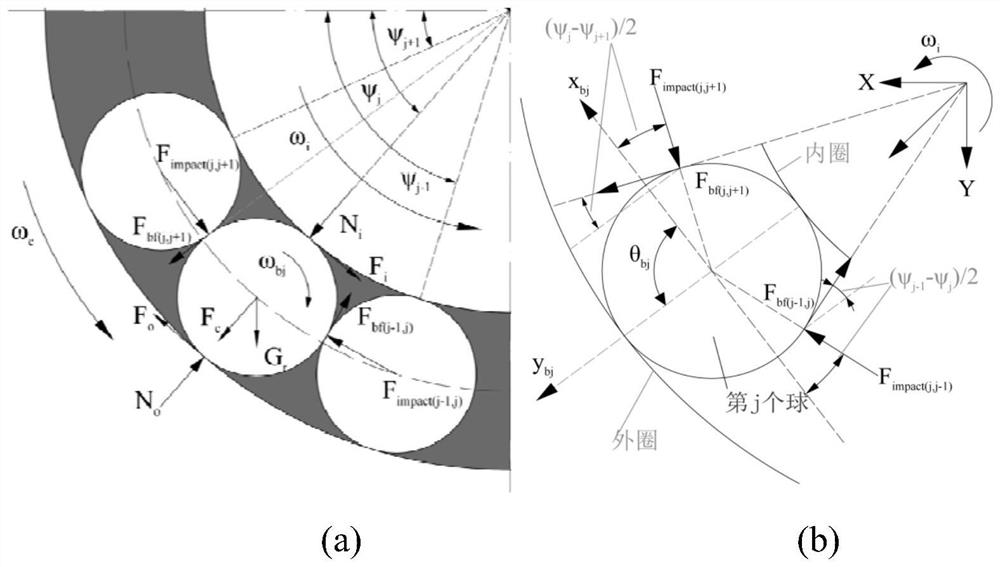

[0047] First, analyze the force and motion of the rolling elements, such as figure 2As shown, first analyze the force of a single rolling element (the jth ball), the inner ring of the bearing will be subjected to the load applied from the main shaft during operation, and the loaded inner ring will exert a downward force on the rolling element, so the rolling element In the normal direction of the contact point with the inner and outer rings, the pressure of the inner ring (N i ) and the reaction force of the outer ring on the rolling elements (N o ). Since the rolling elements move relative to the inner and outer rings in the bearing, and the rolling elements and the inner and outer rings are in contact with each other, the rolling elements will be subject to friction from the inner and outer rings in the tangential direction of the contact point with the inner and outer rings. Force (F o and F i ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com