Diaphragm for waterproof micro loudspeaker

A diaphragm and attachment technology, which is applied in the diaphragm field of high water pressure waterproof micro-speakers, can solve problems such as the influence of waterproof defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

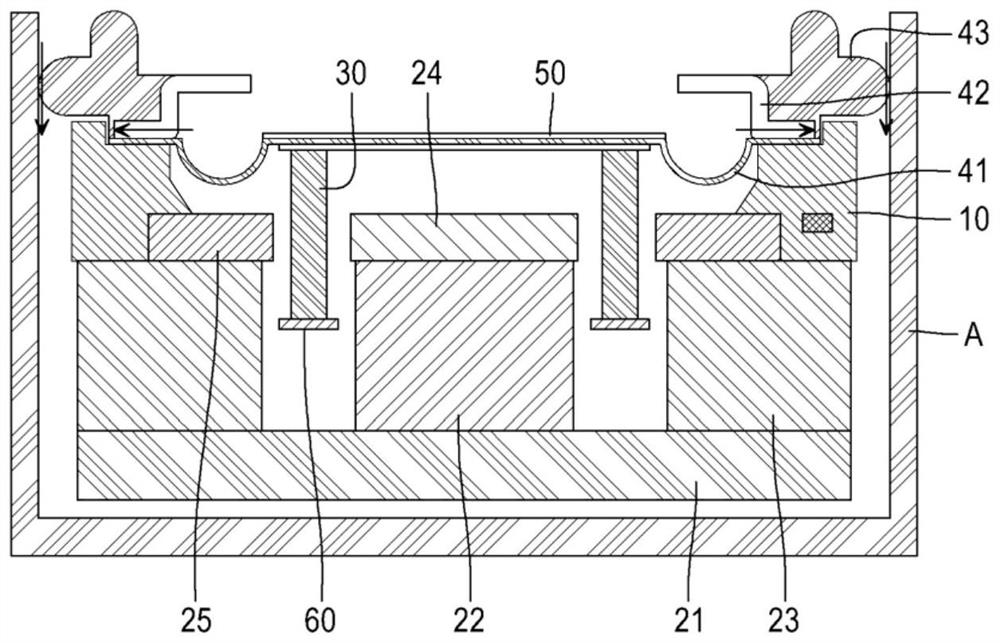

[0028] Hereinafter, the present disclosure will be described in more detail with reference to the accompanying drawings.

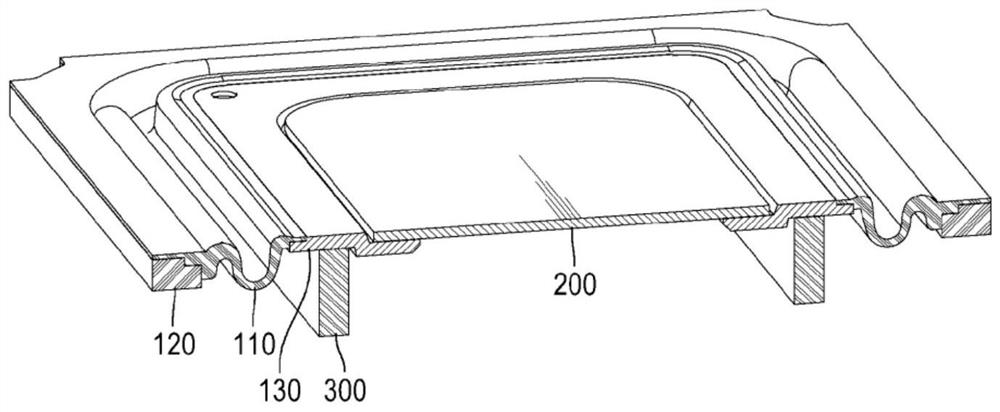

[0029] image 3 are views illustrating a diaphragm for a waterproof microspeaker according to a first embodiment of the present disclosure, and Figure 4 is a cross-sectional view of a diaphragm for a waterproof microspeaker according to a first embodiment of the present disclosure.

[0030] In the diaphragm for a waterproof microspeaker according to the first embodiment of the present disclosure, the center diaphragm 200 is attached to the center of the edge diaphragm 100 to diffuse as a center portion thereof, and the edge diaphragm 100 has an annular shape as a whole.

[0031] The edge diaphragm 100 includes: an annular dome portion formed of an elastic membrane material and having a dome portion protruding upwardly or downwardly; an annular peripheral portion 120 attached to the dome The outer circumference of the segment 110 and is injection molded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com