Hydraulic system oil leakage fault degree detection method based on artificial intelligence

A hydraulic system and fault degree technology, which is applied in the field of detection of hydraulic system oil leakage fault degree based on artificial intelligence, can solve the problem of consuming large human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be introduced below with reference to the accompanying drawings in the embodiments of the present invention.

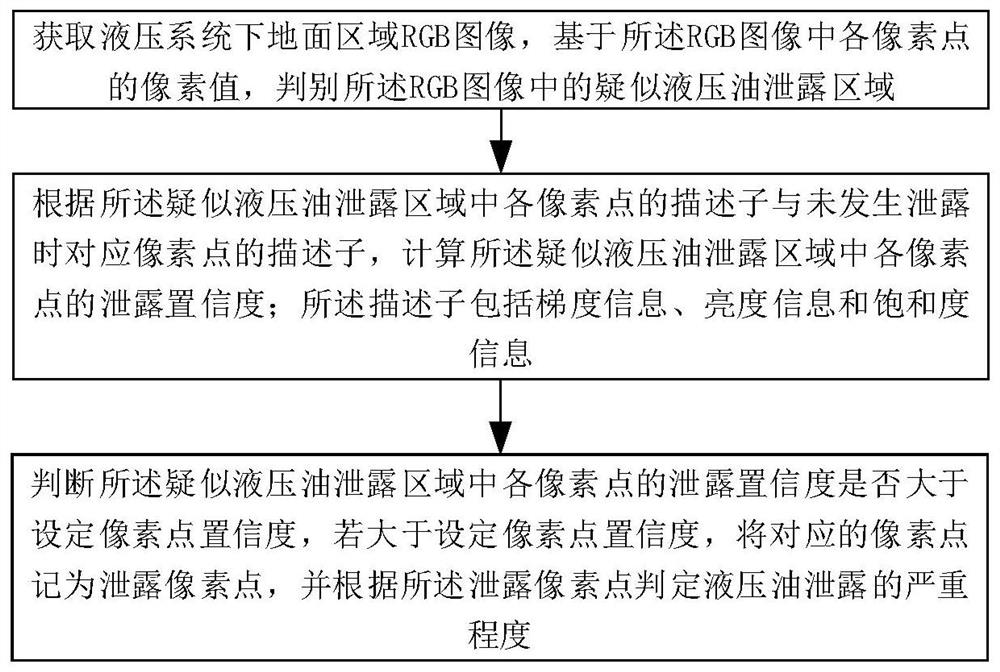

[0028] This embodiment aims to solve the problem of consuming a large amount of human resources when the existing manual detection of hydraulic oil leakage occurs in the hydraulic system, such as figure 1 As shown, the artificial intelligence-based hydraulic system oil leakage fault detection method in this embodiment includes the following steps:

[0029] (1) Obtain the RGB image of the ground area under the hydraulic system, and determine the suspected hydraulic oil leakage area in the RGB image based on the pixel value of each pixel in the RGB image;

[0030] When a hydraulic oil leakage fault occurs in the hydraulic system, the hydraulic oil will flow to the ground bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com