Method for cleaning and disinfecting respiratory loop of anesthesia apparatus and its operation steps

A breathing circuit, cleaning and disinfection technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of a large number of germs and lack of cleaning and disinfection methods for anesthesia machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

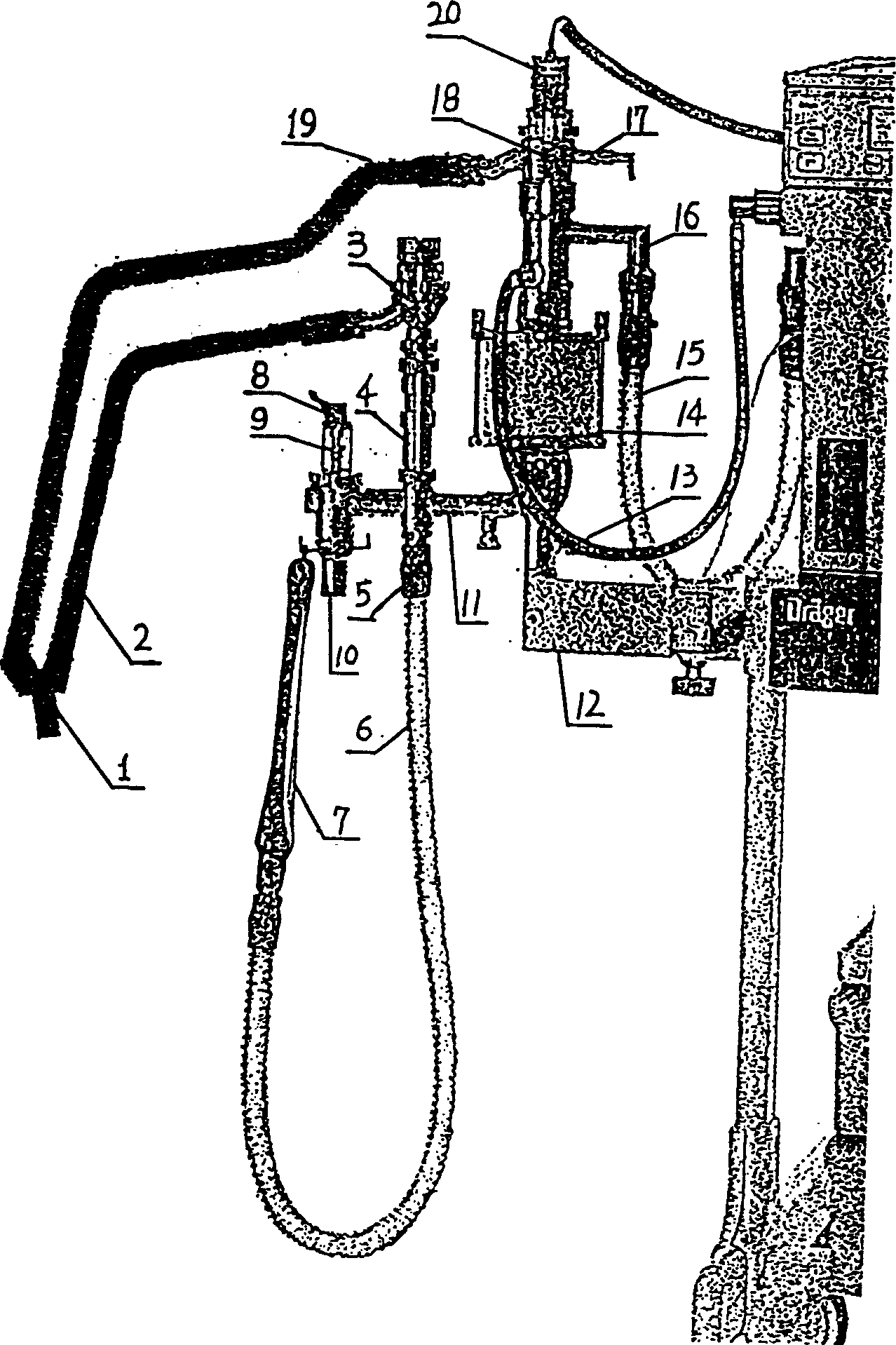

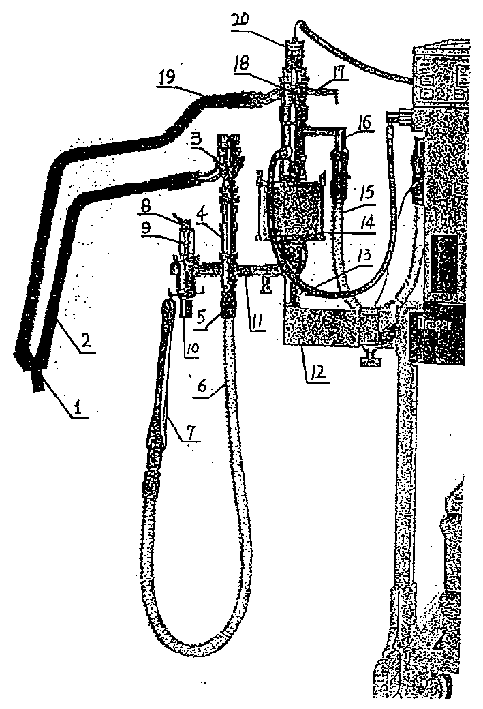

[0007] Referring to the accompanying drawings, 1 in the accompanying drawings is a "Y" type tee joint; 2 is an exhalation threaded pipe; 3 is an exhalation valve; 4 is a flow sensor; 5 is a bladder interface; 10 is the escape gas outlet; 11 is the cross arm of the breathing circuit; 12 is the circuit bracket; 13 is the fresh gas hose; 14 is the soda lime tank; 15 is the ventilator connection hose; 16 is a fresh gas isolation valve; 17 is a pressure test interface; 18 is a suction valve; 19 is a suction threaded pipe; 20 is a sensor of the suction valve. The operation steps are: 1. Plug the "Y" joint 1 connected to the patient with a special plug, turn on the quick oxygen supply switch to make the internal pressure of the machine reach 30cmH 2 O, adjust the oxygen flow until the internal pressure can be maintained, and the oxygen flow at this time is the leakage of the whole machine. 2. Open the APL valve 9 to reduce the internal pressure to "0", then close the APL valve 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com