An aerosol valve

A spray valve and valve stem technology, applied in the direction of injection device, liquid injection device, engine sealing, etc., can solve the problems of non-utilization, leakage of hardness sealing ring characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

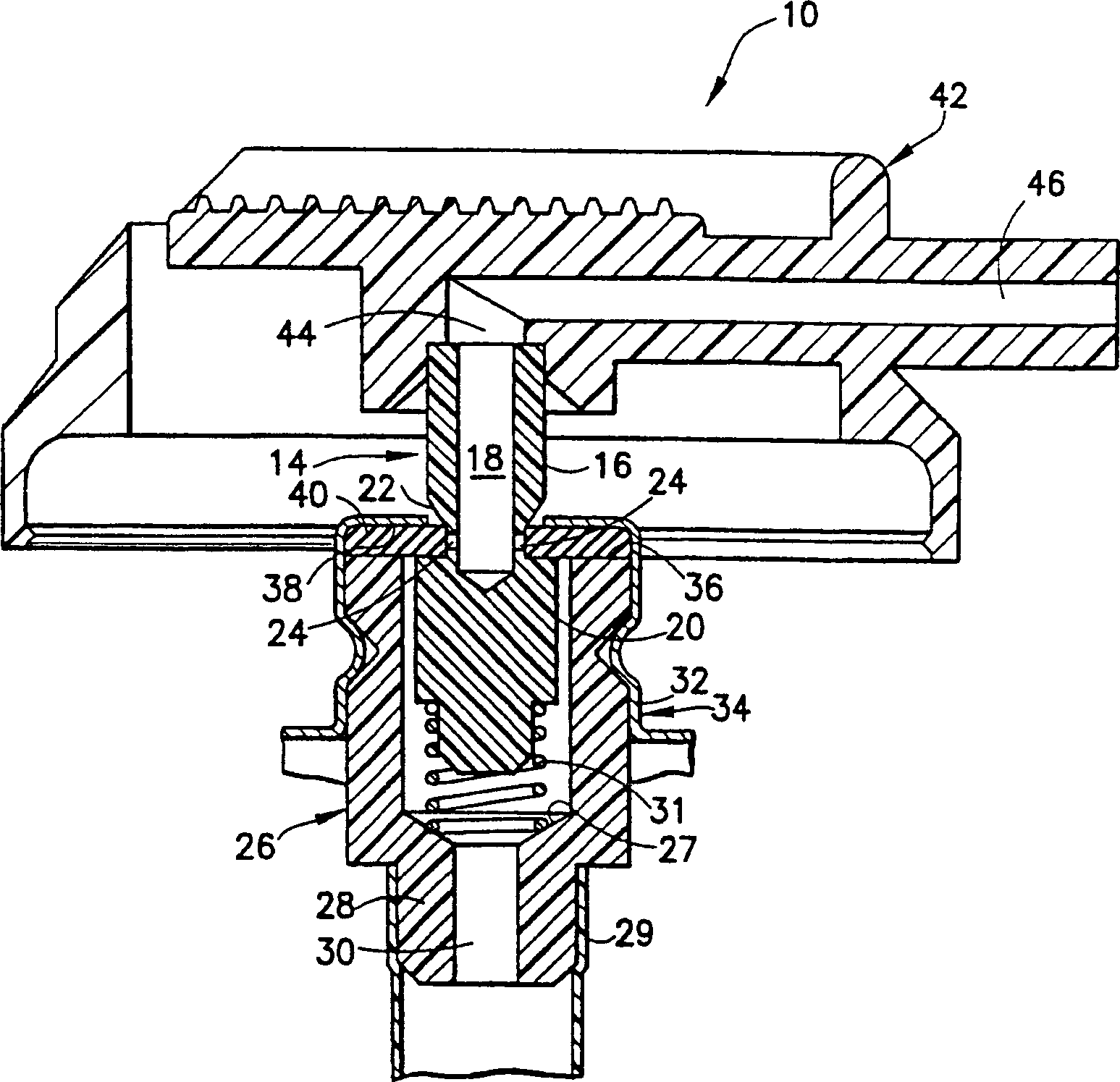

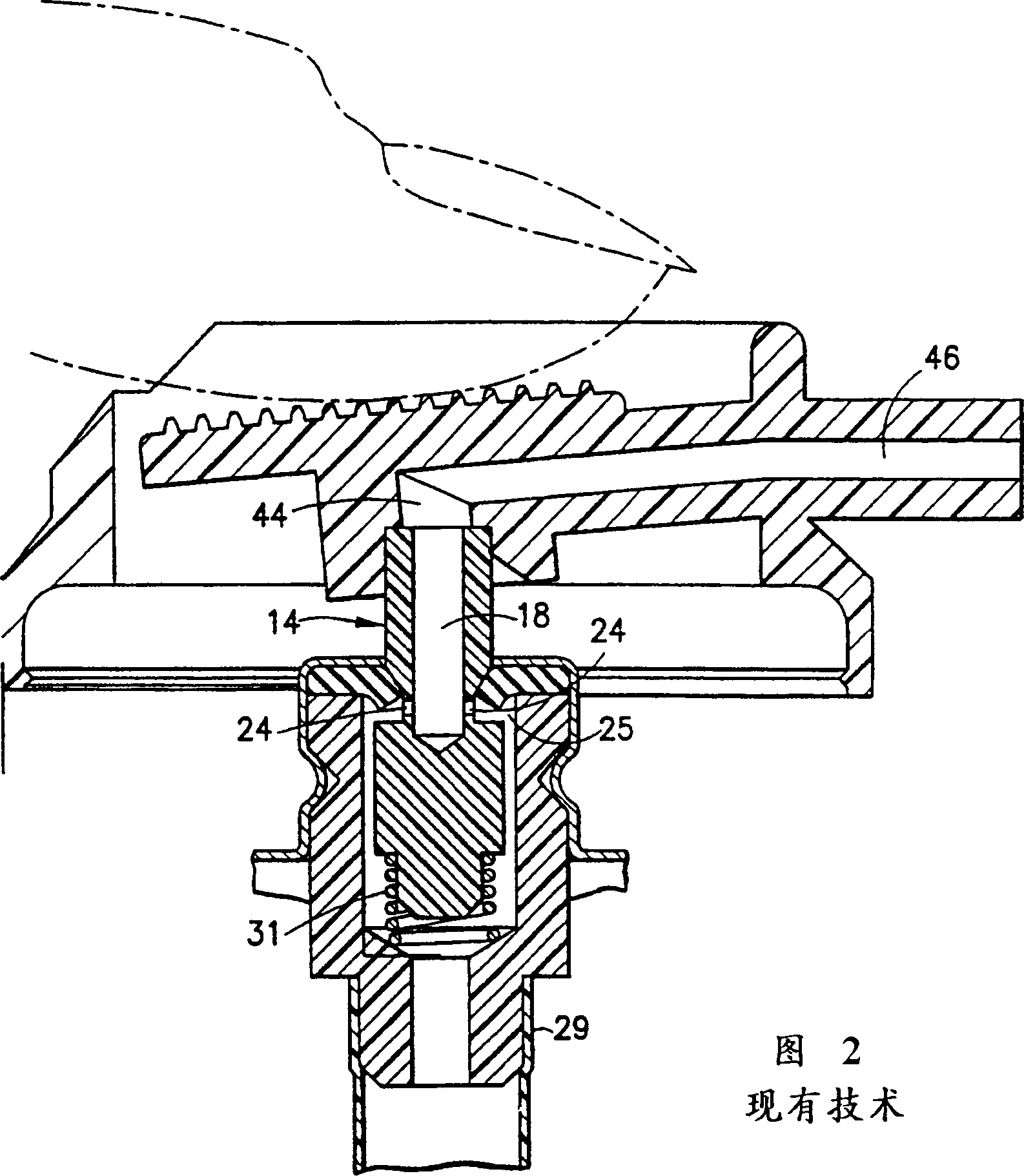

[0015] Figure 1 shows a spray valve assembly, generally indicated by the numeral 10. More specifically, the valve assembly includes: a valve stem / stem body indicated at numeral 14 having an upper valve stem portion 16 through which conduit 18 passes; a valve Stem portion 20 and an annular groove portion 22 in the middle portion between the upper stem portion 16 and the valve stem body portion 20; the groove portion has a hole 24 passing through the wall of the groove portion, and the groove portion passes through the hole and the tube. Road 18 is connected. Valve housing 26 surrounds valve stem body 20, said valve housing has an extended nipple 28 through which conduit 30 passes, nipple 28 designed to accept cannula 29 (shown in FIG. part). The valve housing 26 is captured within a base portion 34 of a mounting cup 34 (partially shown). An annular seal 40 is disposed on top of the upper wall 36 of the valve housing 26 and at the underside 38 of the seat portion 32 to seal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com