Magnetron

A magnetron and pole piece technology, applied in the field of magnetrons, can solve problems such as damage to high-voltage parts, and achieve the effects of preventing discharge and inhibiting the reduction of insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

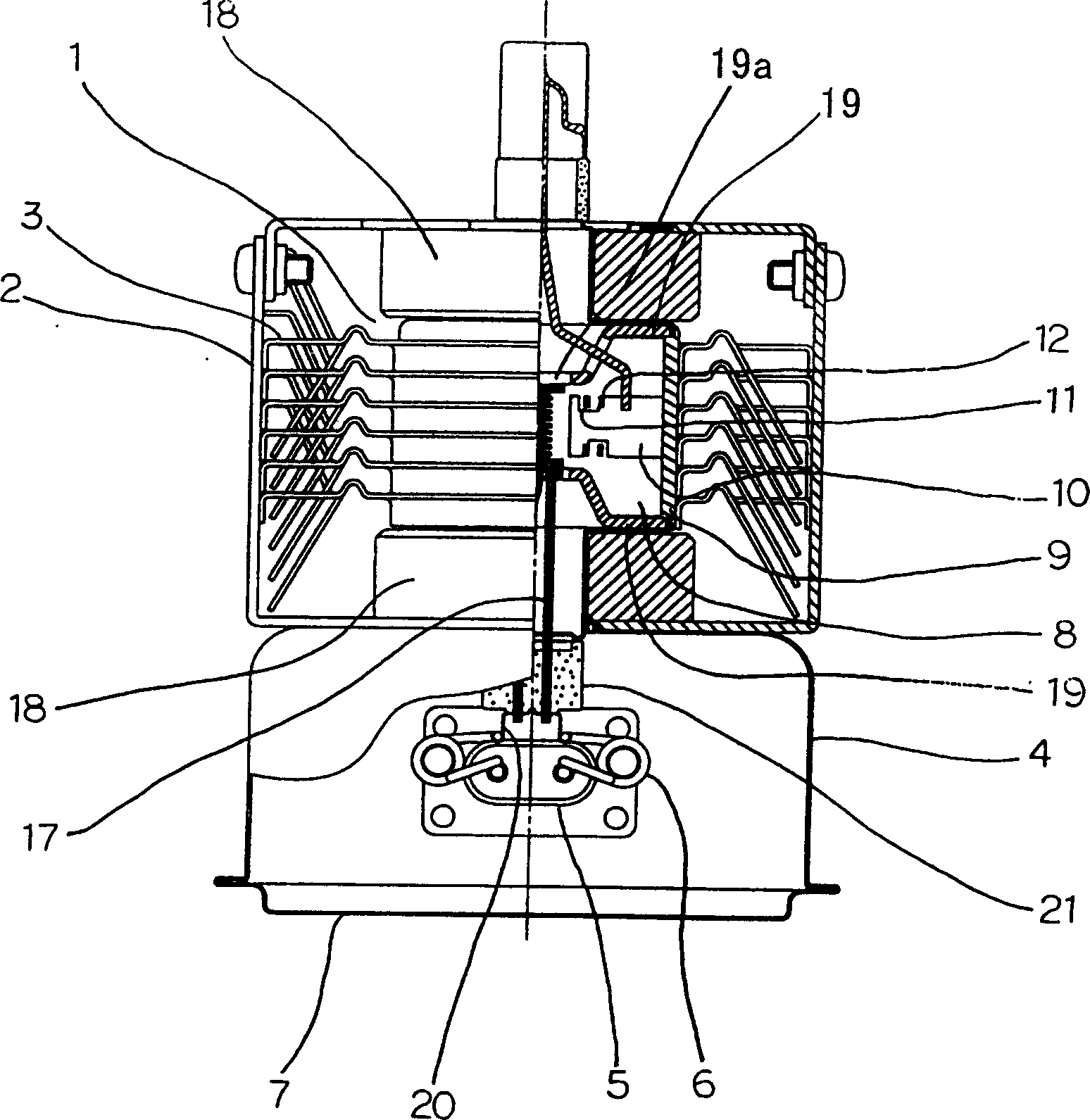

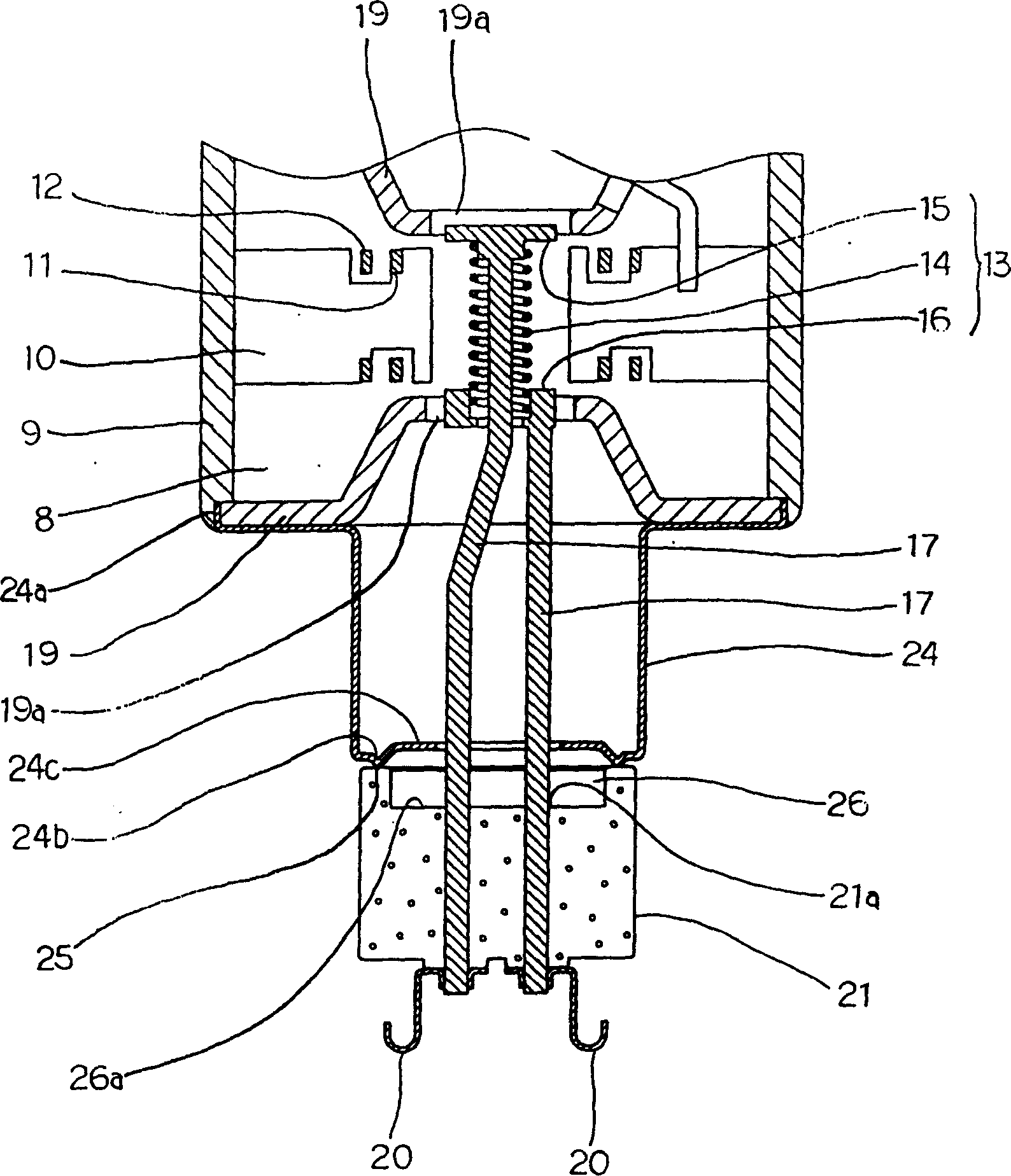

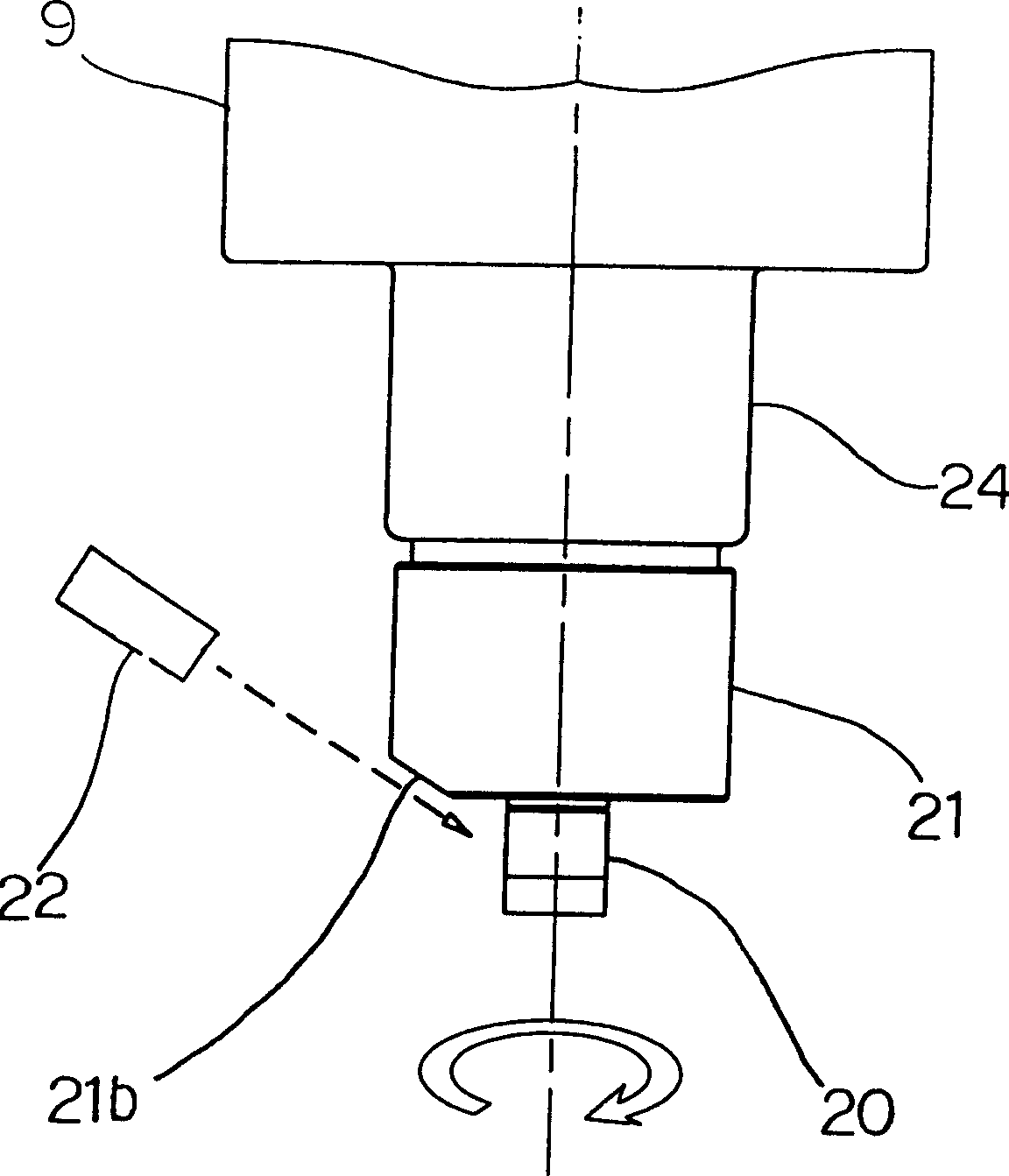

[0019] Embodiment 1 of the present invention will be described in detail based on the drawings.

[0020] figure 1 It is a longitudinal sectional view showing the main part of the magnetron of the first embodiment of the present invention, figure 2 Is a longitudinal section of the same main part, image 3 Is a cross-sectional view of the same main part, Figure 4 Is the top surface view of the same insulator sleeve, Figure 5 It is a diagram showing another embodiment of the insulator sleeve.

[0021] 1 is the main body of the magnetron of the vacuum diode covered by the frame 2 and the heat sink 3.

[0022] 4 is a case in which the capacitor 5 and the choke coil 6 for noise suppression are installed inside, and the cover 7 is attached to the opening of the case 4 so that the noise does not leak to the outside.

[0023] 8 is the anode of the magnetron. The anode 8 is made of oxygen-free copper. The anode cylinder 9 that forms a part of the vacuum wall of the main body 1 is used....

Embodiment 2

[0037] Hereinafter, Embodiment 2 of the present invention will be described based on the drawings. The same numbers are attached to the same structures in the first embodiment described above, and the descriptions are omitted.

[0038] Figure 6 It is a longitudinal sectional view of the main part of Example 2 of the present invention.

[0039] 27 is a cylindrical metal container in which one end 27a is joined to the anode 8 and the other end 27b is brazed and hermetically joined to the joining surface 25 formed around the insulator sleeve 21.

[0040] 27c is a bent portion formed in the cylindrical metal container 27 and bent from the other end opening 27b to the bottom surface 26a of the recess 26, and the bent portion 27c is formed to cover the entire bottom surface 26a of the recess 26. With this structure, even if metal objects such as thorium and tungsten are evaporated from the surface of the filament 14, because the bent portion 27c covers the entire wall surface 26b of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com