Wind power generation system

A wind power generation system and wind turbine technology, which are applied in the directions of wind energy generation, wind turbines, and wind turbine combinations to achieve the effects of large phase-to-phase mutual inductance, reduction of harmonic components, and suppression of sudden increase in current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a wind power generation system, including a wind power generator and at least two power conversion circuits, each power conversion circuit has the same phase number, and the wind power generator is connected to each power conversion circuit. Wherein, the power conversion circuit is used to receive the electric energy output by the wind power generator, and perform frequency conversion and output. Among them, at least two power conversion circuits are redundant with each other. When one of the power conversion circuits or a coil connected to a certain phase of the power conversion circuit fails, the corresponding power conversion circuit can be cut off, and the remaining power conversion circuits can work normally and continue to operate. Output Power.

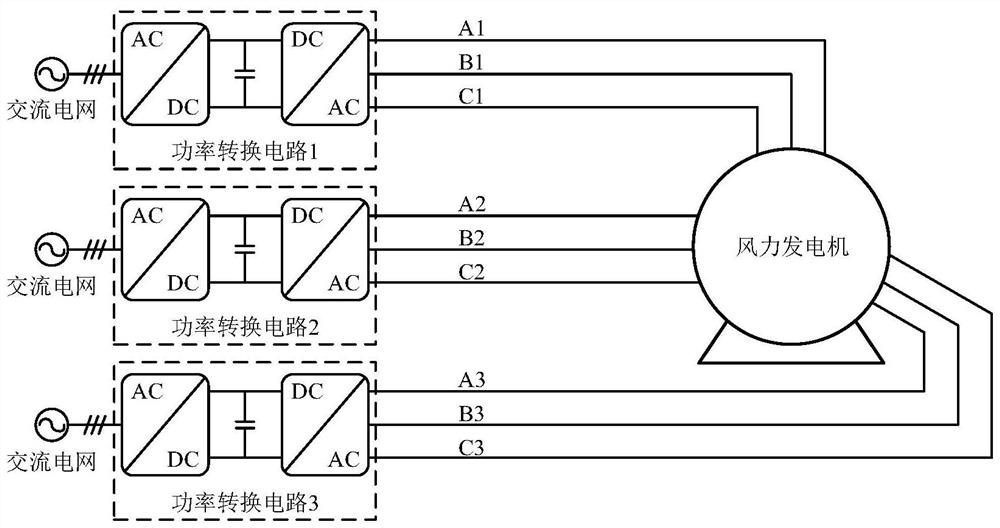

[0062] figure 1 It is a schematic diagram showing a circuit topology of a wind power generation system. like figure 1 The wind power generation system shown includes three power conversion cir...

Embodiment 2

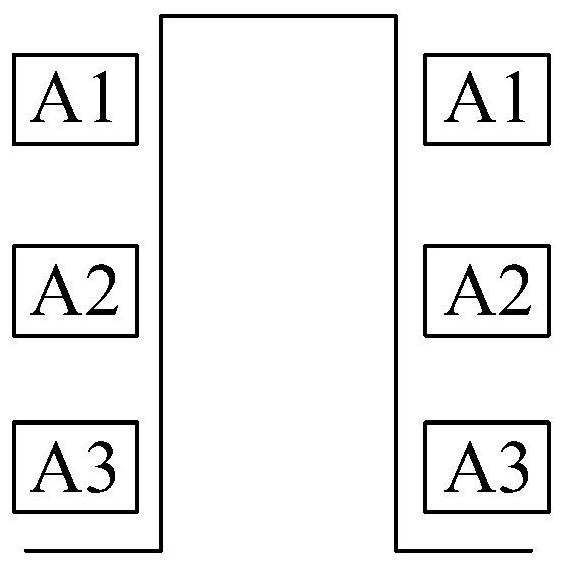

[0082] On the basis of Embodiment 1, this embodiment also provides a wind power generation system, the difference from Embodiment 1 is: the number of power conversion circuits connected to the coils wound on different stator teeth belonging to the same stator tooth group same.

[0083] In an optional implementation manner, the coils wound at the same position on different stator teeth belonging to the same stator tooth group have the same connection relationship with each phase of the power conversion circuit.

[0084] In this embodiment, when the coils on different stator teeth in the same stator tooth group are connected in series, since the coils connected to the same power conversion circuit are at the same radial position, the coils in these stator tooth groups are not connected after being connected. There will be overlap, and the connection between the coils is shorter and the spatial distribution is more concise. In addition, when the coil adopts the end welding proce...

Embodiment 3

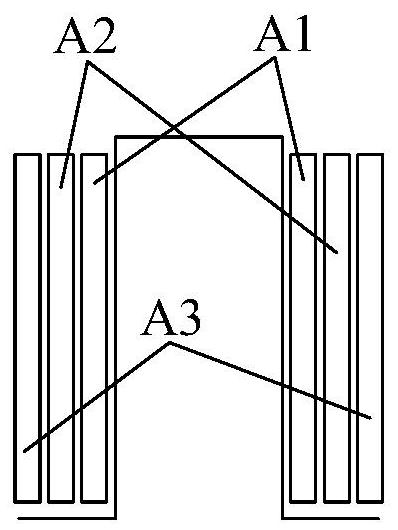

[0106] On the basis of Embodiment 1, this embodiment also provides a wind power generation system, the difference from Embodiment 1 is: the number of power conversion circuits connected to the coils wound on different stator teeth belonging to the same stator tooth group different.

[0107] In an optional implementation manner, at least two different numbers of coils are wound on the stator teeth belonging to the same stator tooth group.

[0108] In an optional implementation manner, the k coils belonging to the same stator tooth are respectively connected to the same phase of the k power conversion circuits, where k is an integer greater than or equal to 2.

[0109] In an optional embodiment, the number of coils wound on the stator teeth of at least two periods in one stator unit is repeated.

[0110] In an optional embodiment, in one stator unit, the coils wound at the same position on the first stator tooth are connected to the same power conversion circuit, wherein the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com