Jump test for CD recording groove

A technology for recording tracks and optical discs, applied to disc-shaped recording carriers, optical recording carriers, recording information on magnetic disks, etc., can solve problems such as indetermination of control devices, and achieve the effect of reducing unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method and apparatus for track jump detection during reading and / or writing of an optical disc is disclosed herein. In the following description, for purposes of explanation, specific nomenclature and specific implementation details are set forth in order to provide a thorough understanding of the invention. It will be apparent, however, to one skilled in the art that these specific details are not required in order to practice the present invention. For example, the preferred embodiment is described in the context of a DVD+RW disc, but the techniques of the present invention are equally applicable to other forms of optical discs.

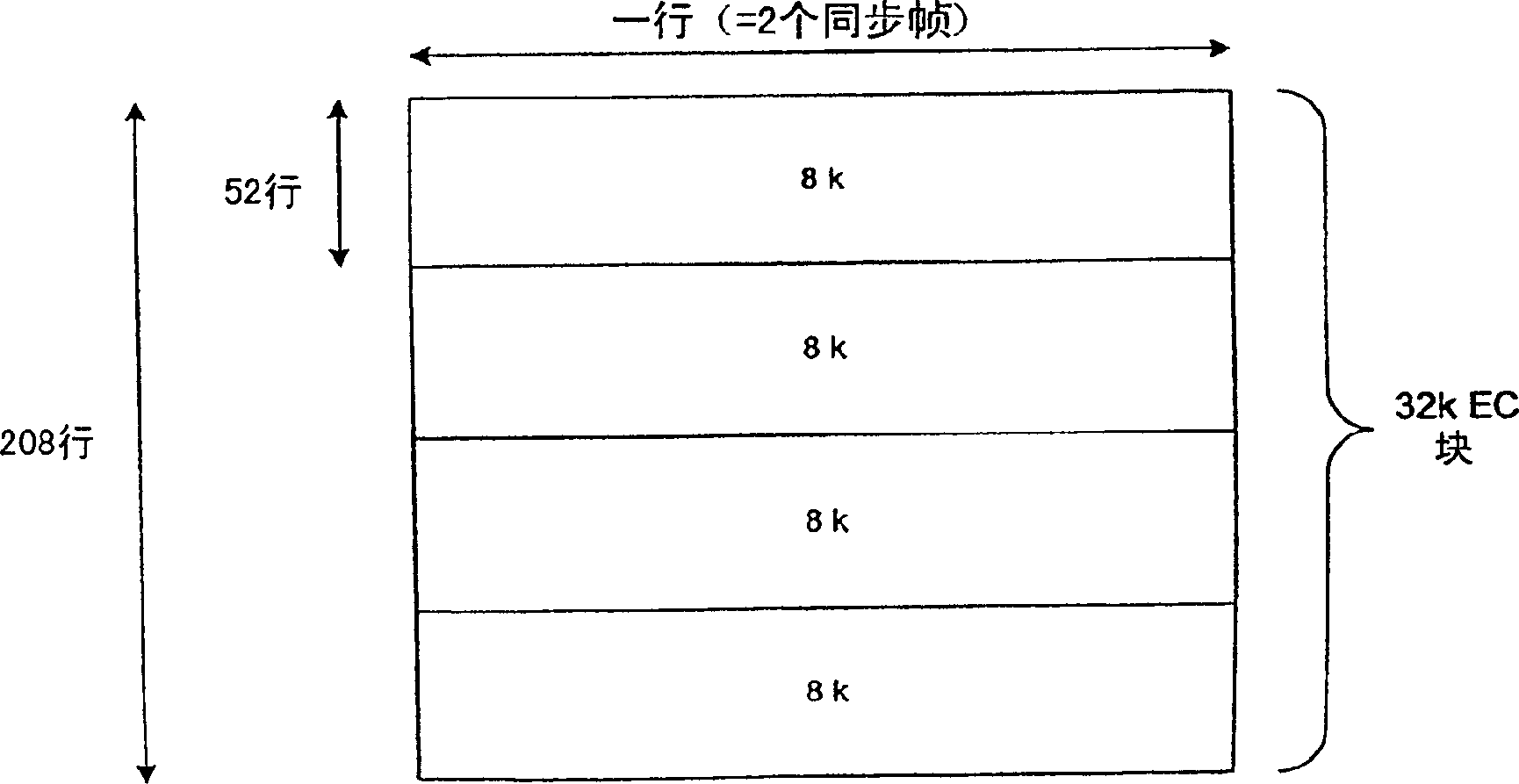

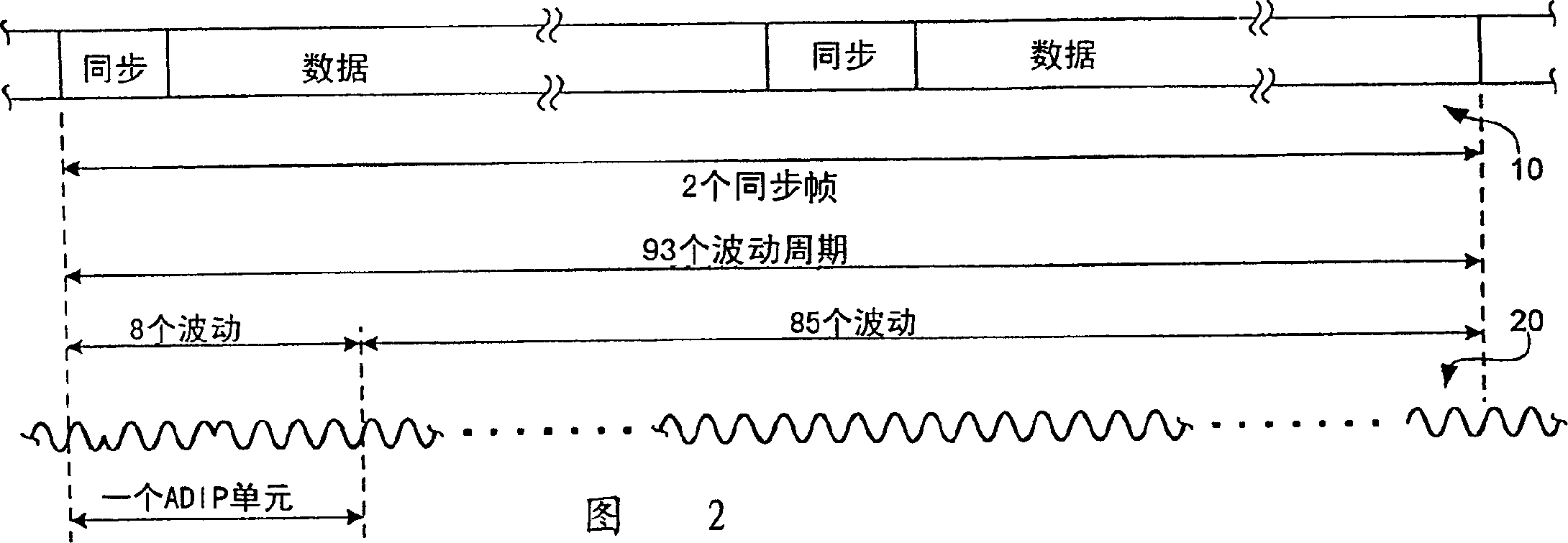

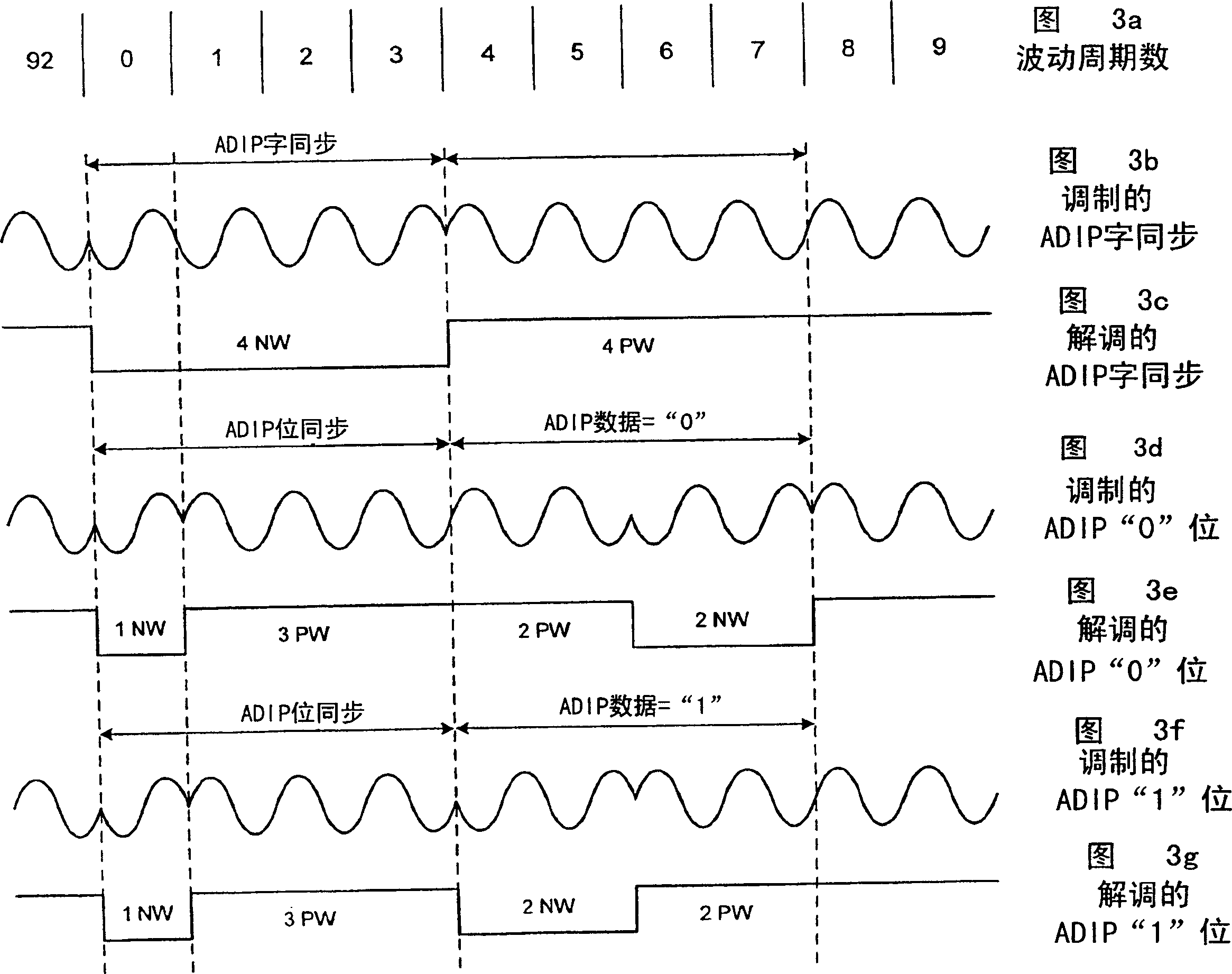

[0014] As mentioned above, data is stored on a typical optical disc in terms of the tracks that are created on the disc during the manufacturing process. The spiral tracks created on the disc during manufacture are sometimes referred to as pre-grooves. In the case of a Digital Versatile Disc (DVD), for example, the tracks are generated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com