Glass material coating method for flat type CRT, coating device, seal device and method thereof

A coating device and glass frit technology, applied in electrical components, discharge tube/lamp manufacturing, tube/lamp screen manufacturing, etc., can solve the problems of unstable frit, unstable frit quantity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments according to the present invention will be described below with reference to the drawings.

[0039] In this embodiment, a case will be described in which sealing treatment with frit is applied to the flat type glass tube assembly 6 of the flat type cathode ray tube 1 described above.

[0040] Similar to the above, the flat glass tube assembly 6 is composed of three parts, namely a first plate, in this embodiment a flat panel 2, a second plate, in this embodiment having a curved surface and a raised Partially shaped screen 3 and funnel 4 comprising a neck 7 in which the rising portion is a so-called skirt portion 3a formed along three sides.

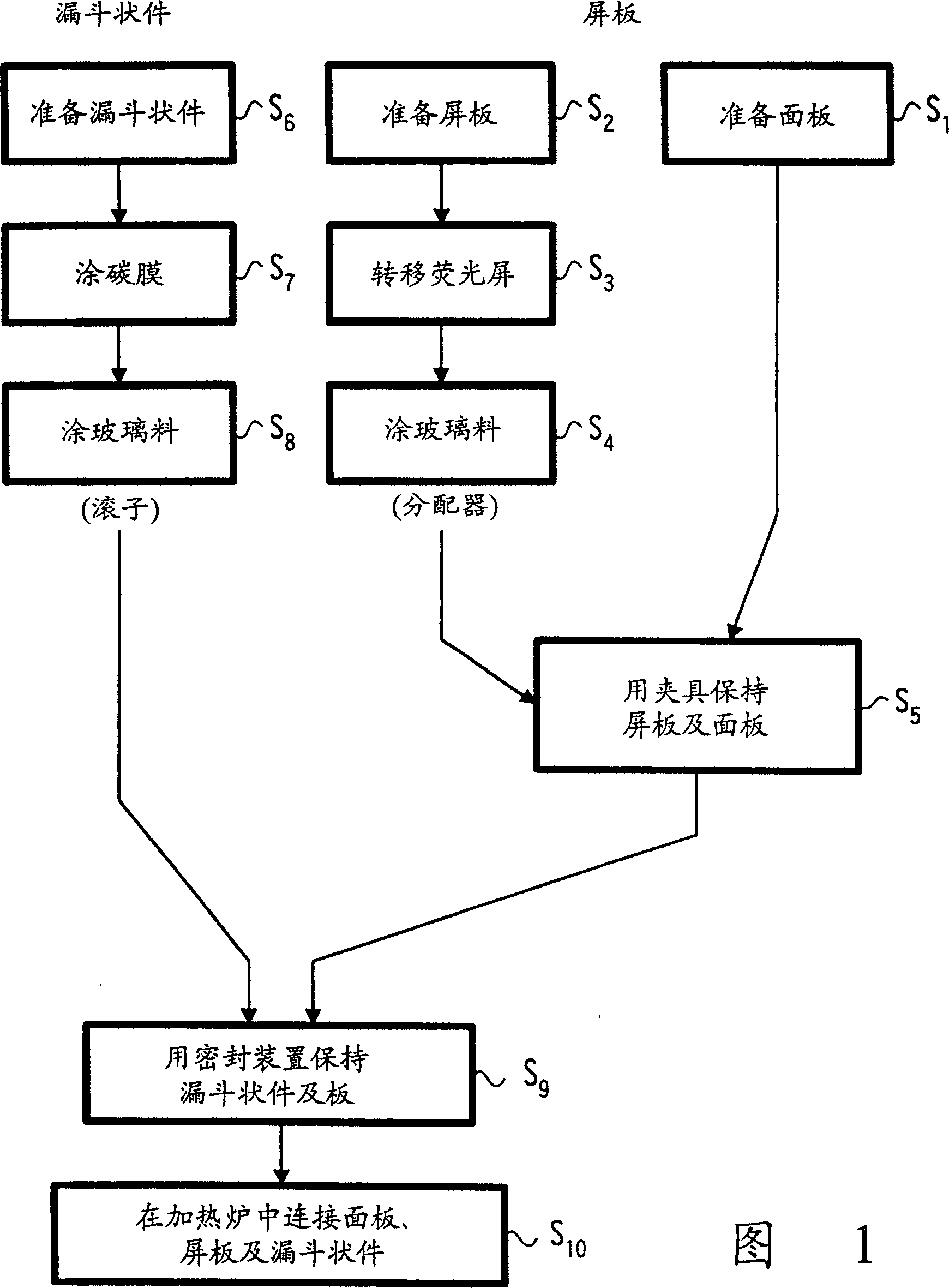

[0041] FIG. 1 shows a flow chart of the sealing process of the flat glass tube assembly 6 . Prepare the panel 2, the screen plate 3 and the funnel 4. In step S 2 In the prepared panel 3, its inner surface will be 3Phosphor screen 3 is formed on it. Phosphor screen 3 can be formed by, for example, a transfer method....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com