Adhesive-tape cutting knife

A tape and cutter technology, used in printing, office supplies, sending objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

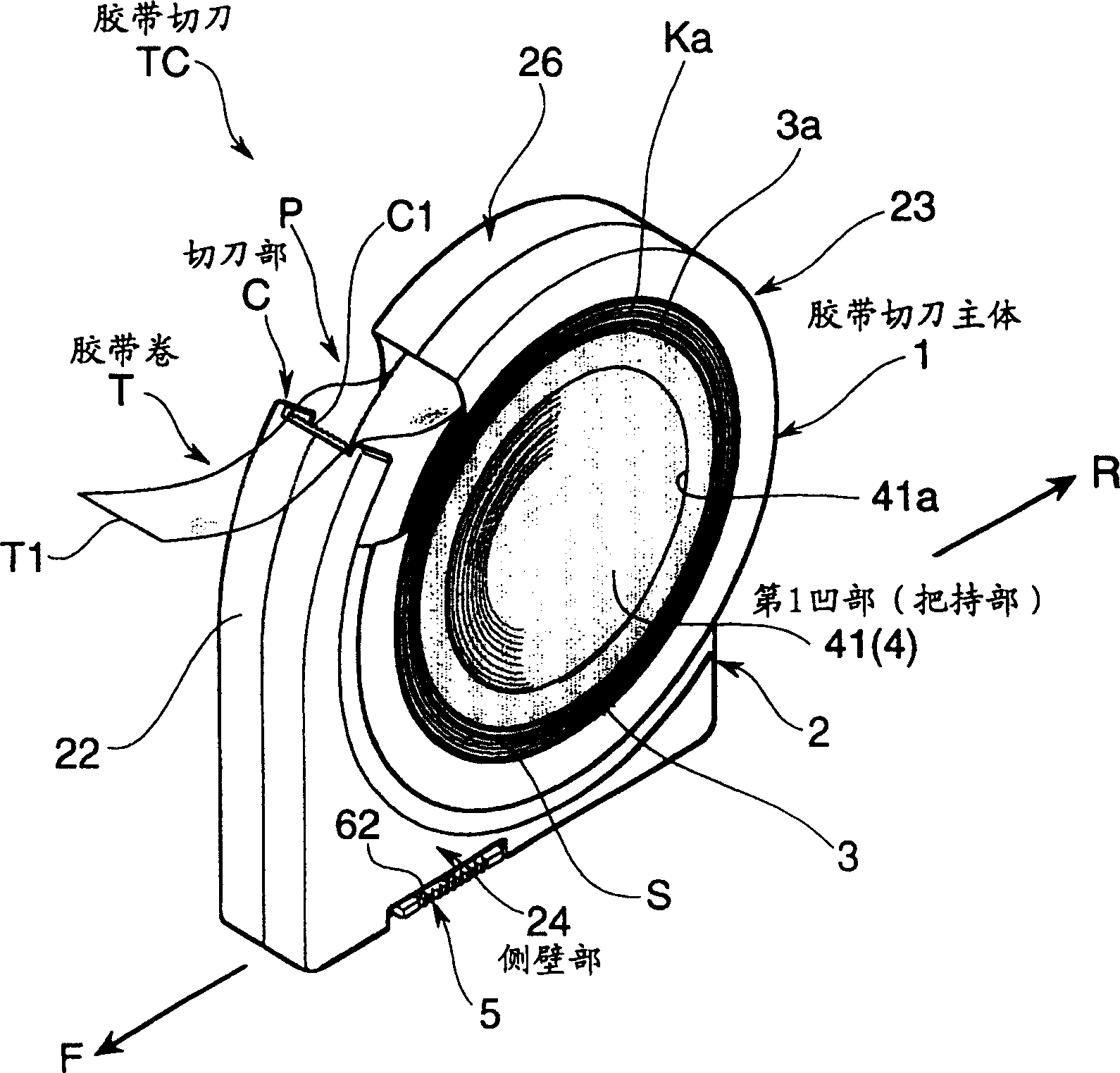

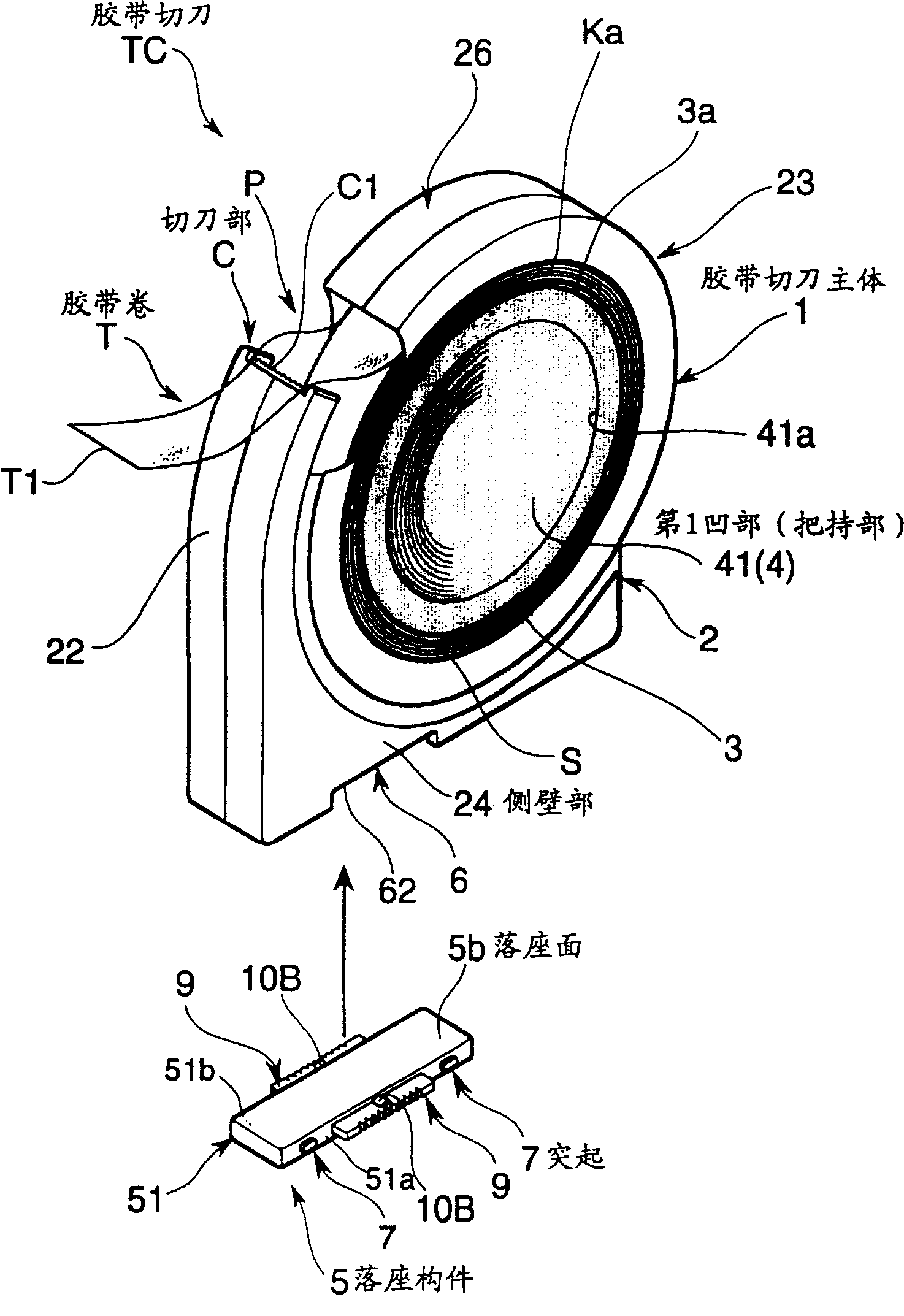

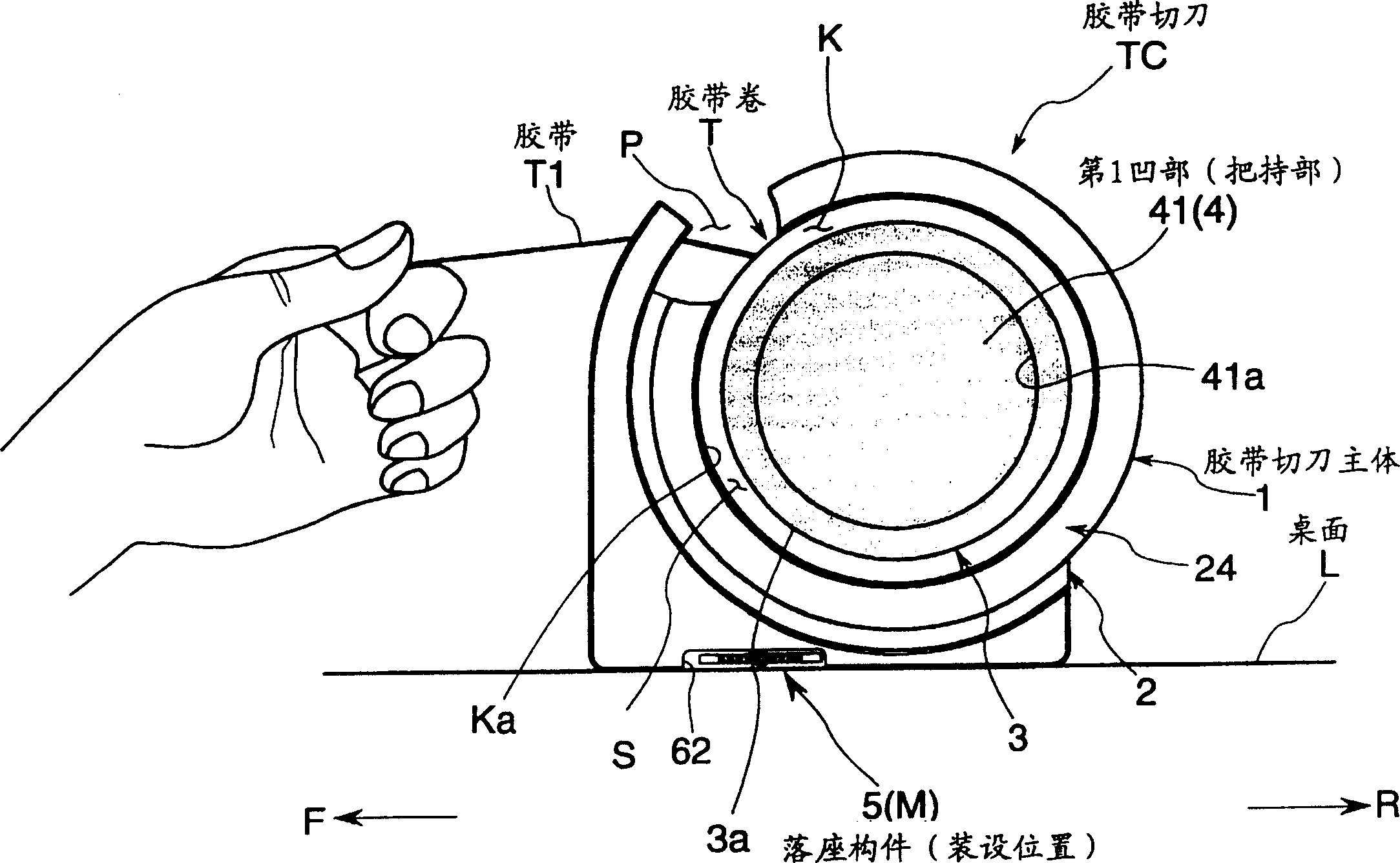

[0037] An embodiment of the present invention will be described below with reference to the accompanying drawings.

[0038] The tape cutter TC in this embodiment is used in offices, schools, or personal homes, etc., and has a cutter for holding the tape roll T rotatably and pulling out the tape T1 constituting the tape roll T and cutting it to an appropriate length. The main body 2 of the tape cutter of part C, and the seat member 5. In addition, the tape cutter TC of this embodiment is configured so that it can be used separately image 3 The first use mode in which the tape T1 is pulled out from the tape roll T by hand when the cutter portion C is positioned on the table top L as a predetermined placement surface is shown in FIG. and Figure 4 As shown in , the end portion of the aforementioned tape T1 is fixed in a state where the aforementioned cutter portion C is positioned on the lower end side, and the aforementioned tape T1 is pulled out by holding the bottom side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com