Automatic calorimeter in electrolytic process

A calorimetric device and automatic technology, applied in the field of calorimetry, can solve the problems of unable to solve the problem of real-time accurate calorimetry, and cannot meet the problems of real-time storage of massive test data for ultra-long continuous work, and achieve remote access to databases and resource sharing. Ease of promotion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure, measurement principle, operation process and embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

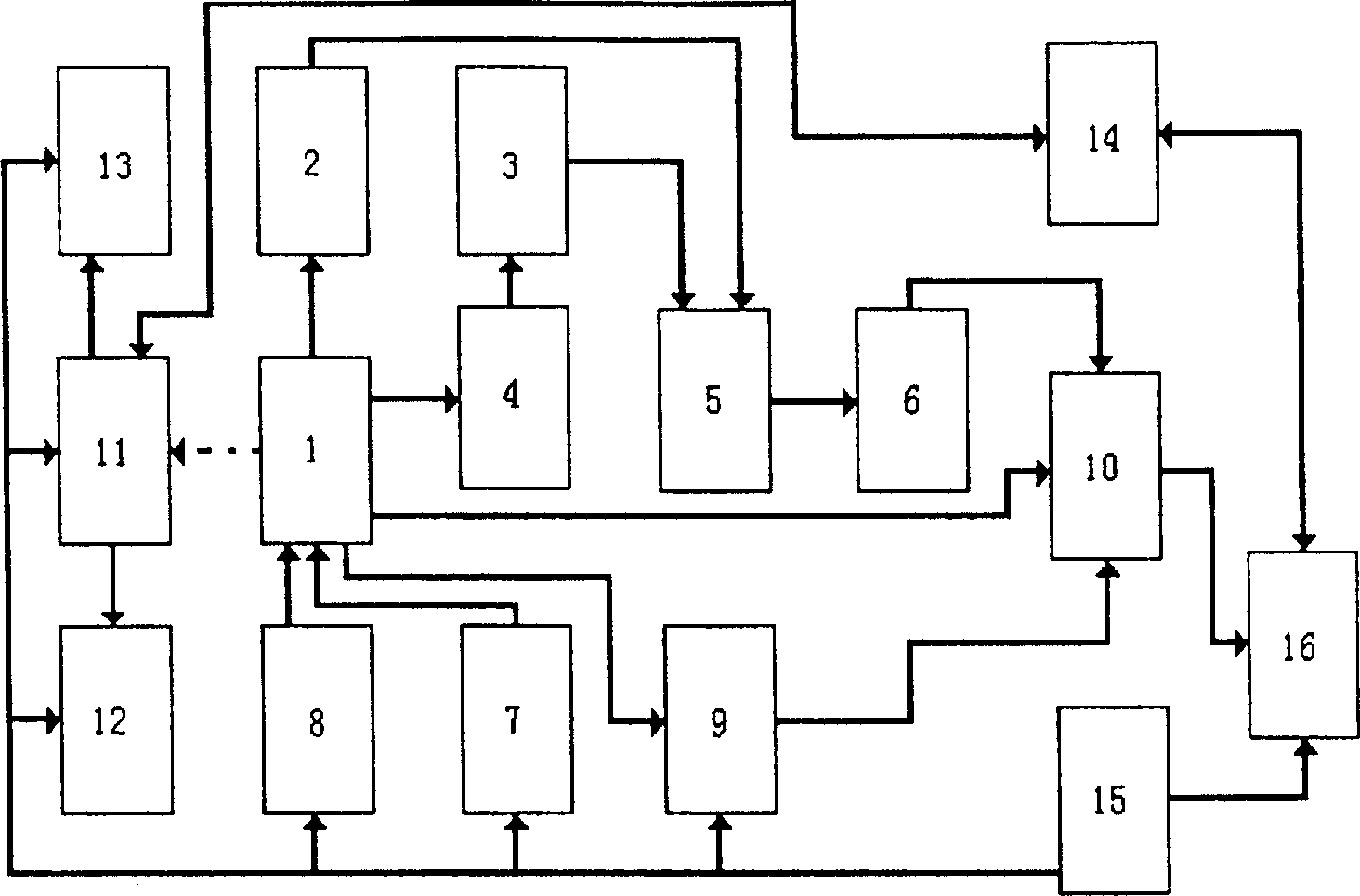

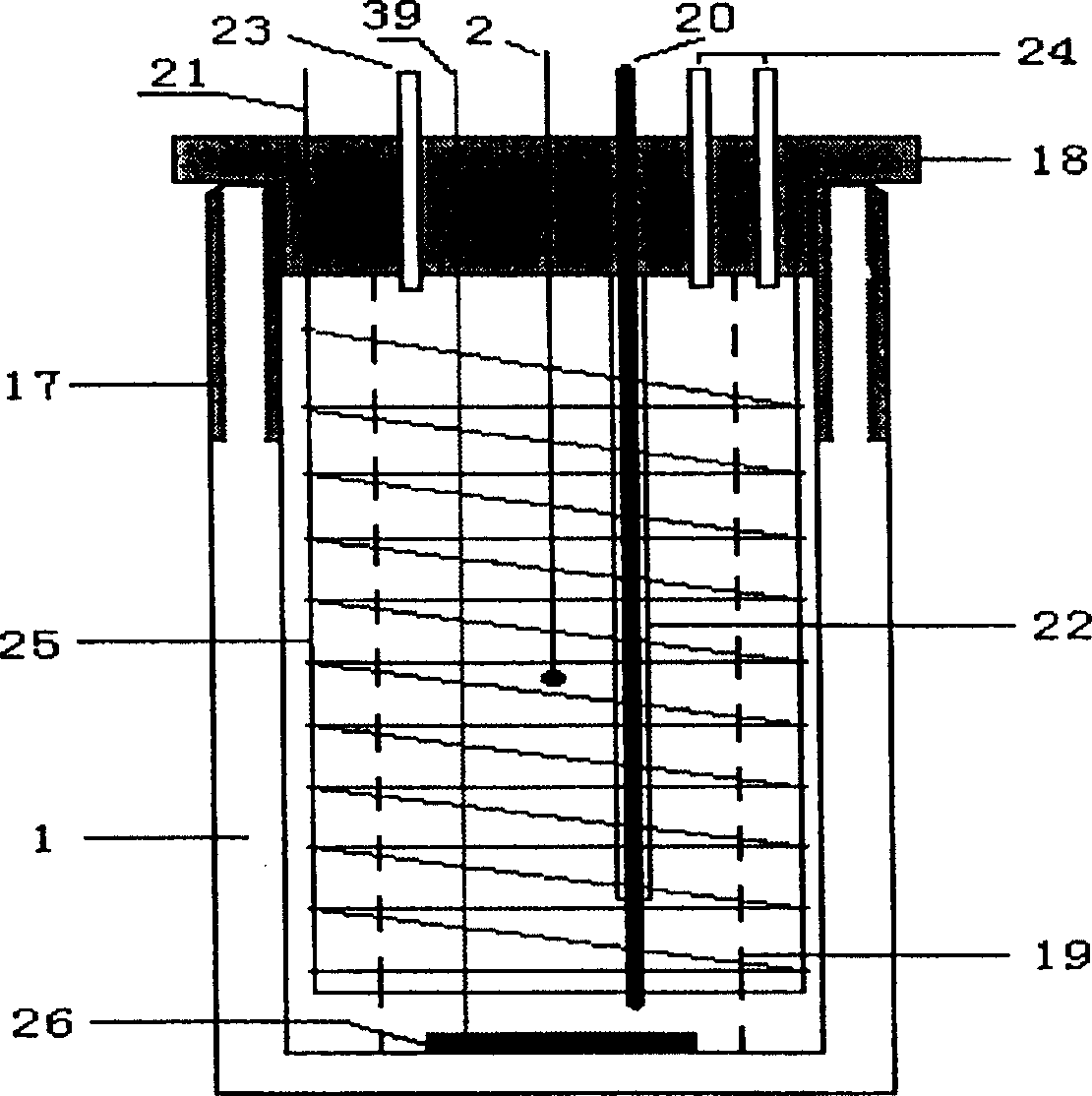

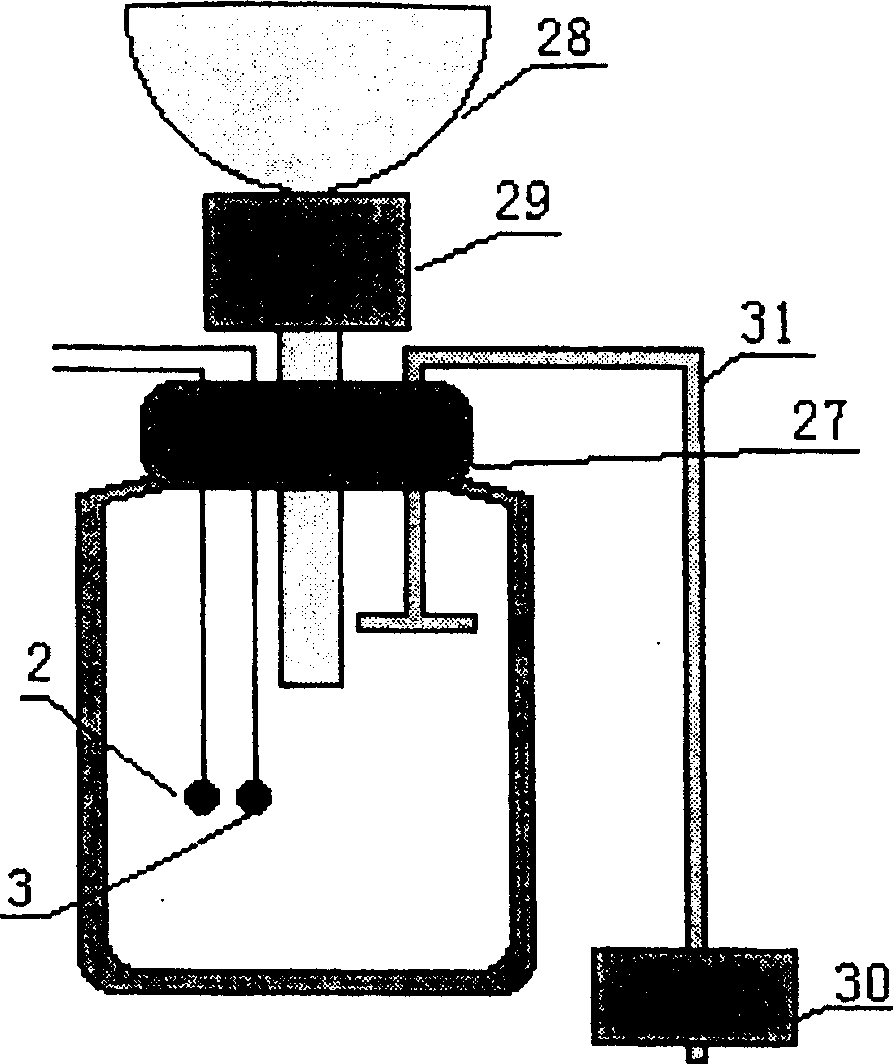

[0031] figure 1 In the block diagram of the open electrolytic cell 1, the traditional calorimeter is replaced by the open electrolytic cell, and the thermocouples 2 and 3, the constant temperature bath 4, the freezing point stabilizer 5, the thermocouple signal conditioner 6, and the heat Calibration power supply 7, electrolytic DC power supply 8, air pressure sensor 9, converter-interface A / D-I / O 10, miniature camera 11, long-time video recorder 12, large-screen monitor 13, image converter 14 and UPS uninterruptible power supply 15.

[0032] The open electrolyzer 1 of this device is connected with one end of the thermocouple 2, and one end of the thermocouple 3 is connected with the constant temperature bath 4, and the electrolyzer is also communicated with the constant temperature bath, that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com