A method for measuring the fuel volume of a vehicle fuel tank

A measurement method and fuel tank technology, which can be used in measuring devices, liquid level indicators for physical variable measurement, liquid/fluid solid measurement, etc., and can solve problems such as potential safety hazards, increased vehicle costs, and expensive precision fuel sensors , to achieve the effect of no change in vehicle cost and fine oil quantity conversion data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

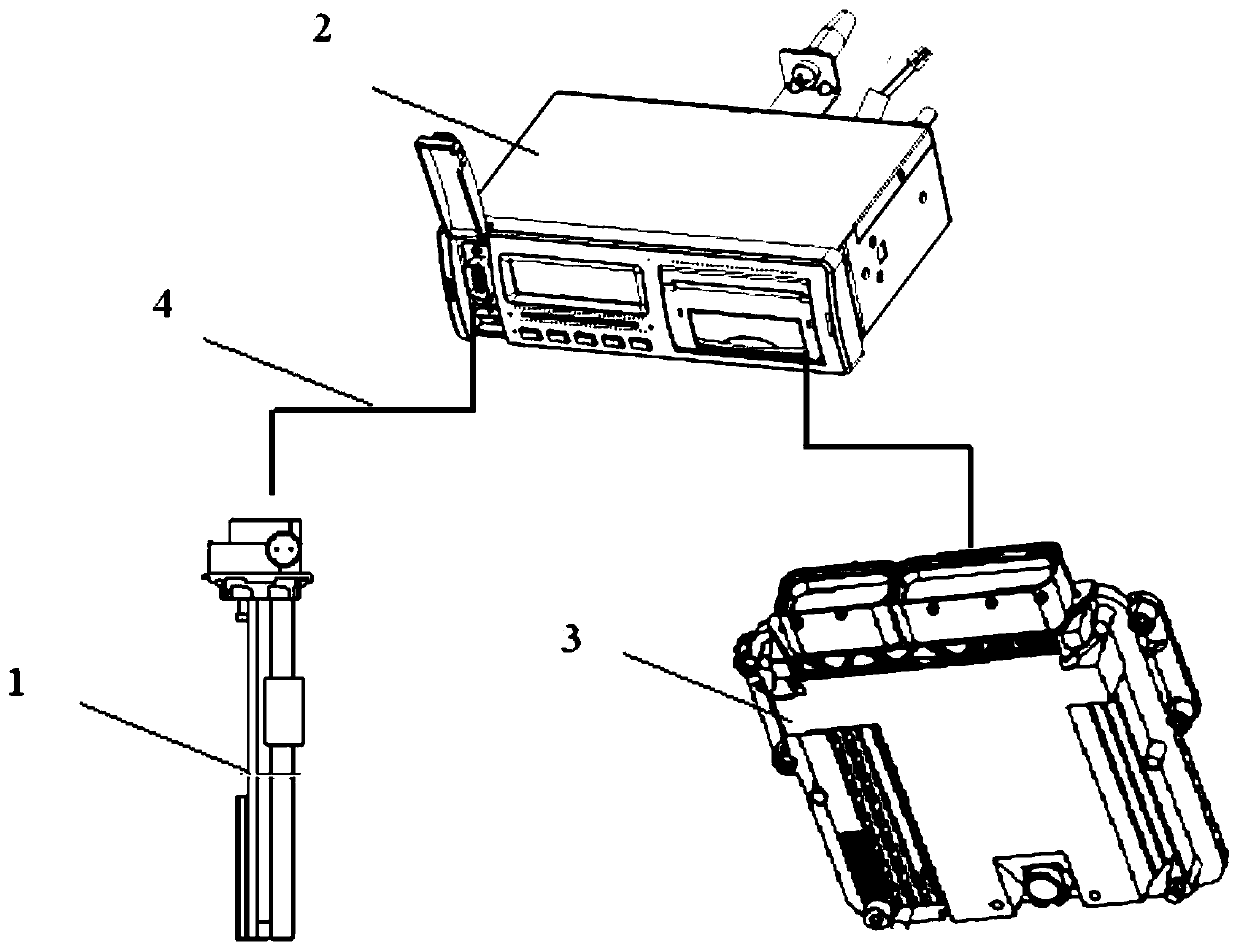

[0017] The invention provides a method for measuring the fuel quantity of a vehicle fuel tank, wherein the main components include a fuel quantity sensor 1 , a vehicle-mounted terminal 2 , an engine controller 3 and a wire 4 .

[0018] Specifically include the following steps:

[0019] S1. Calibration of fuel tank parameters: When the vehicle is off-line, calibrate the fuel tank volume of the vehicle in the vehicle terminal 2, the resistance value of each gear corresponding to the fuel quantity sensor 1 at a certain temperature, the corresponding table of fuel quantity and density, and the fuel temperature and density. Density correspondence table; the fuel density corresponding to fuel quantity sensor 1 at a fixed temperature is fixed;

[0020] S2. Measurement: Find the calibrated fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com