Discharge paint for electronic device and method for making same

A technology of electronic devices and coatings, applied in the field of electric light sources, can solve problems such as cumbersome operation process, affect production efficiency, and large loss of raw materials, and achieve the effect of simple operation process, simple discharge method, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Disclosed is a discharge paint for electronic devices, which contains tritiated ethylene polymer.

[0010] The preparation method of tritiated ethylene polymer is:

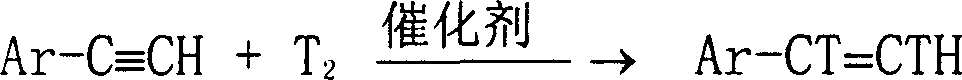

[0011] Step 1: under the action of a catalyst, pass tritium gas into acetylene to make addition reaction of acetylene to generate tritiated ethylene, the reaction is as follows:

[0012]

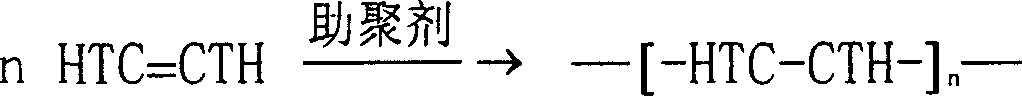

[0013] Step 2: Tritiated ethylene undergoes a polymerization reaction under the action of a polymerization promoter to generate a tritiated ethylene polymer. The response is as follows:

[0014]

[0015] Among them, 0.0371g of 5% palladium carbon catalyst, 0.0327g of azobisisobutyronitrile as a polymerization aid, 0.3524g of acetylene, and 81.6ml of tritium gas. Polymerization temperature: 100°C, reaction pressure: 0.0395 MPa, polymerization time: 90 minutes. The generated tritiated ethylene polymer and polyethylene are in a mass ratio of 1:10 4 Mix, and then prepare the tritium compound finished product...

Embodiment 2

[0017] Disclosed is a discharge paint for electronic devices, which contains tritiated styrene polymer.

[0018] The preparation method of tritiated styrene polymer is:

[0019] Step 1: under the action of a catalyst, pass tritium gas into phenylacetylene to make addition reaction of phenylacetylene to generate tritiated styrene, the reaction is as follows:

[0020]

[0021] Step 2: tritiated styrene undergoes a polymerization reaction under the action of a polymerization promoter to generate a tritiated styrene polymer. The response is as follows:

[0022]

[0023] Among them, 0.0525g of Lindra catalyst, 0.0511g of azobisisobutyronitrile as a polymerization promoter, 0.9352g of phenylacetylene, and 387ml of tritium gas. Polymerization temperature: 100°C, reaction pressure: 0.0445 MPa, polymerization time: 90 minutes. The generated tritiated styrene polymer and polystyrene are in a mass ratio of 1:1.2×10 4 Mix, and then prepare the tritium compound finished p...

Embodiment 3

[0025] Disclosed is a discharge paint for electronic devices, which contains tritiated propylene polymer.

[0026] The preparation method of tritiated propylene polymer is:

[0027] Step 1: Under the action of a catalyst, pass tritium gas into propyne, so that propyne undergoes an addition reaction to generate tritiated propylene, and the reaction is as follows:

[0028]

[0029] Step 2: tritiated propylene undergoes a polymerization reaction under the action of a polymerization aid to generate a tritiated propylene polymer. The response is as follows:

[0030]

[0031] Wherein palladium alumina catalyst 0.1025g, azobisisobutyronitrile 0.03622g, propyne 0.9213g, tritium gas 193ml. Polymerization temperature: 100°C, reaction pressure: 0.0498 MPa, polymerization time: 90 minutes. The generated tritiated propylene polymer and polypropylene are in a mass ratio of 1:1.5×10 4 Mix, and then prepare the tritium compound finished product that meets the activity requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com