Garbage crushing device capable of feeding materials under negative pressure

A technology of garbage crushing and negative pressure, applied in grain processing and other directions, can solve the problems of difficult to take out garbage, affect work efficiency, increase worker burden, etc., and achieve the effect of simple structure, simple discharge method and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

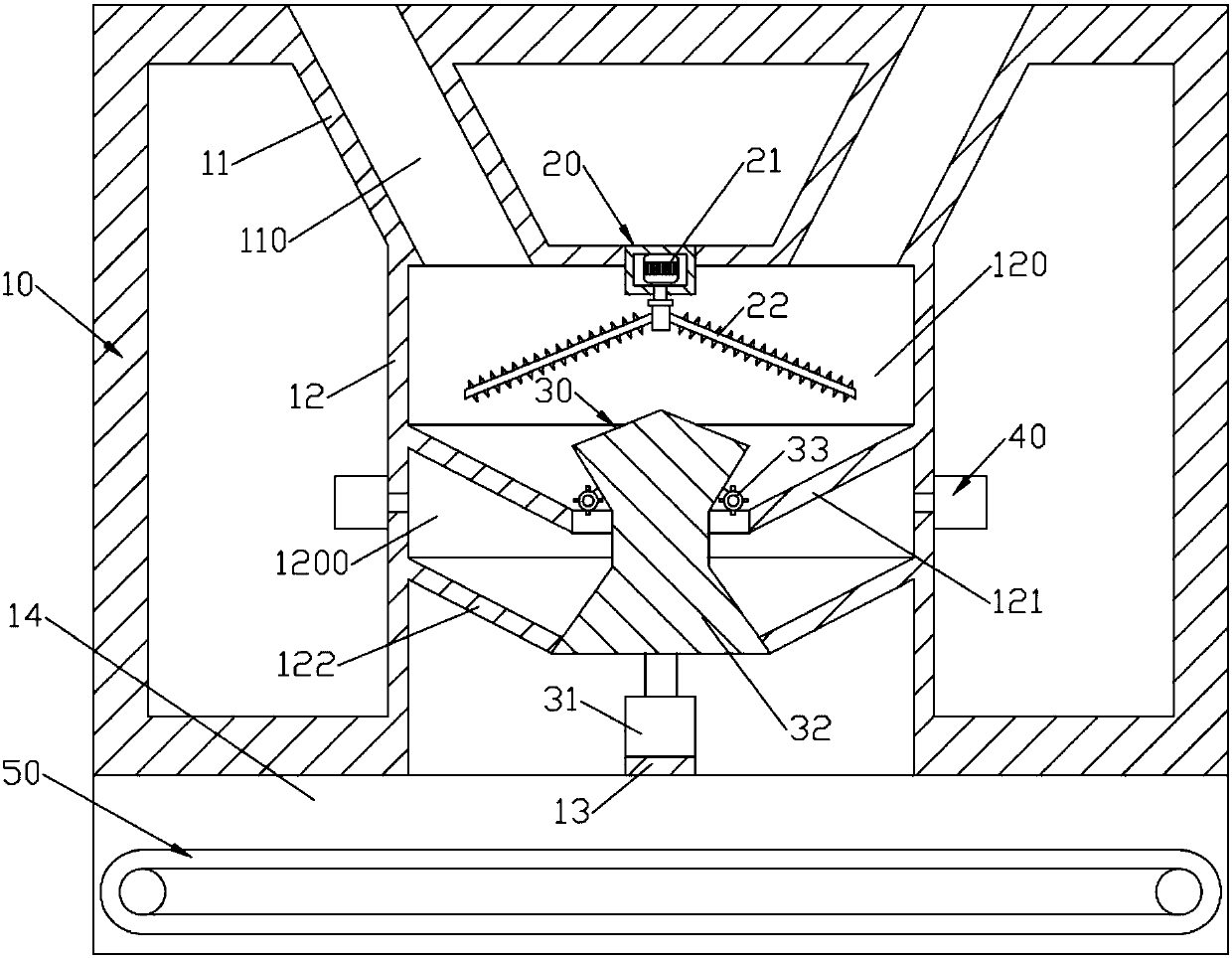

[0015] like figure 1 As shown, a garbage crushing device for negative pressure blanking includes a support frame 10, a crushing unit 20, a lifting opening and closing device 30 and a conveyor belt device 50; the support frame 10 is a cuboid with a rectangular empty cavity formed inside; the support frame 10 A pair of left-right symmetrical feed guide blocks 11 are formed on the upper side wall of the support frame 10; a cylindrical crushing and blanking tube 12 without a lower sealer is formed on the lower side wall of the support frame 10; the lower end of the feed guide block 11 is fixed At the top of the crushing and blanking barrel 12; the feed guide block 11 is formed with an inwardly inclined downward feeding guide hole 110 and the feeding guide hole 110 communicates with the inner cavity of the crushing and blanking barrel 12; the inner side of the crushing and blanking barrel 12 A ring-shaped crushing isolation ring 121 and a closed isolation ring 122 are formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com