Pressure filter

A filter press and filter cloth technology, applied in the field of filter presses, can solve problems such as difficulty and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

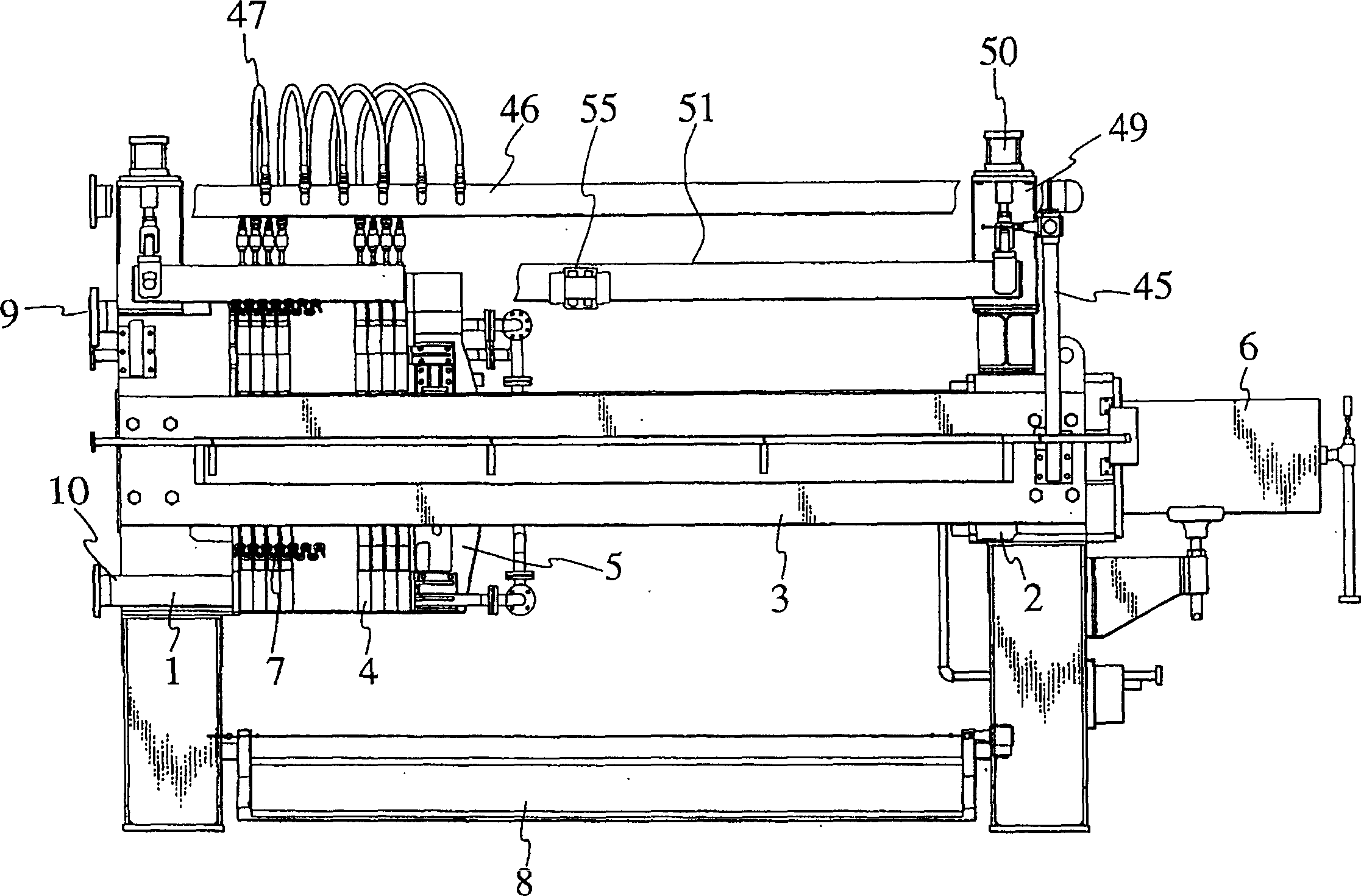

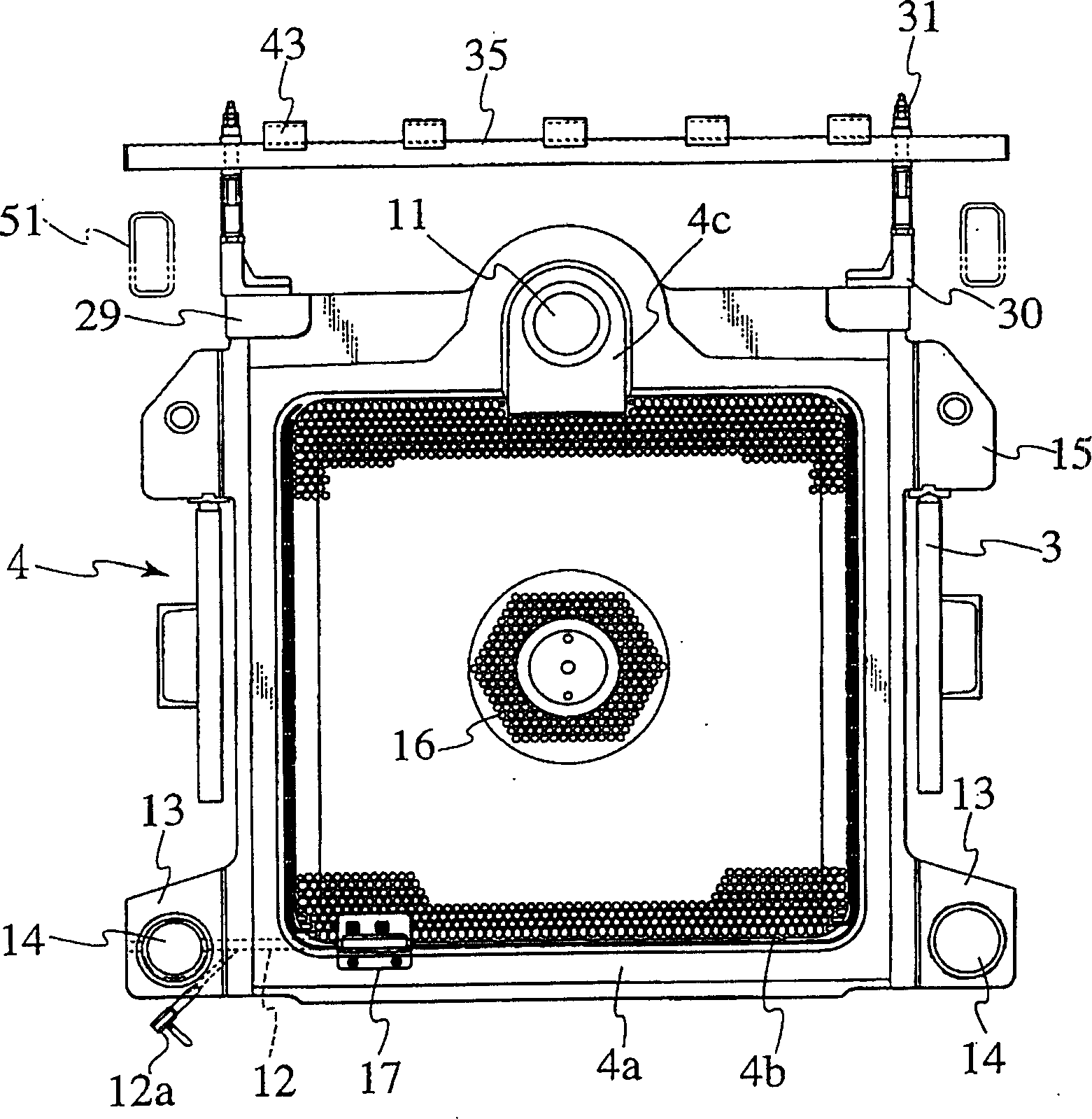

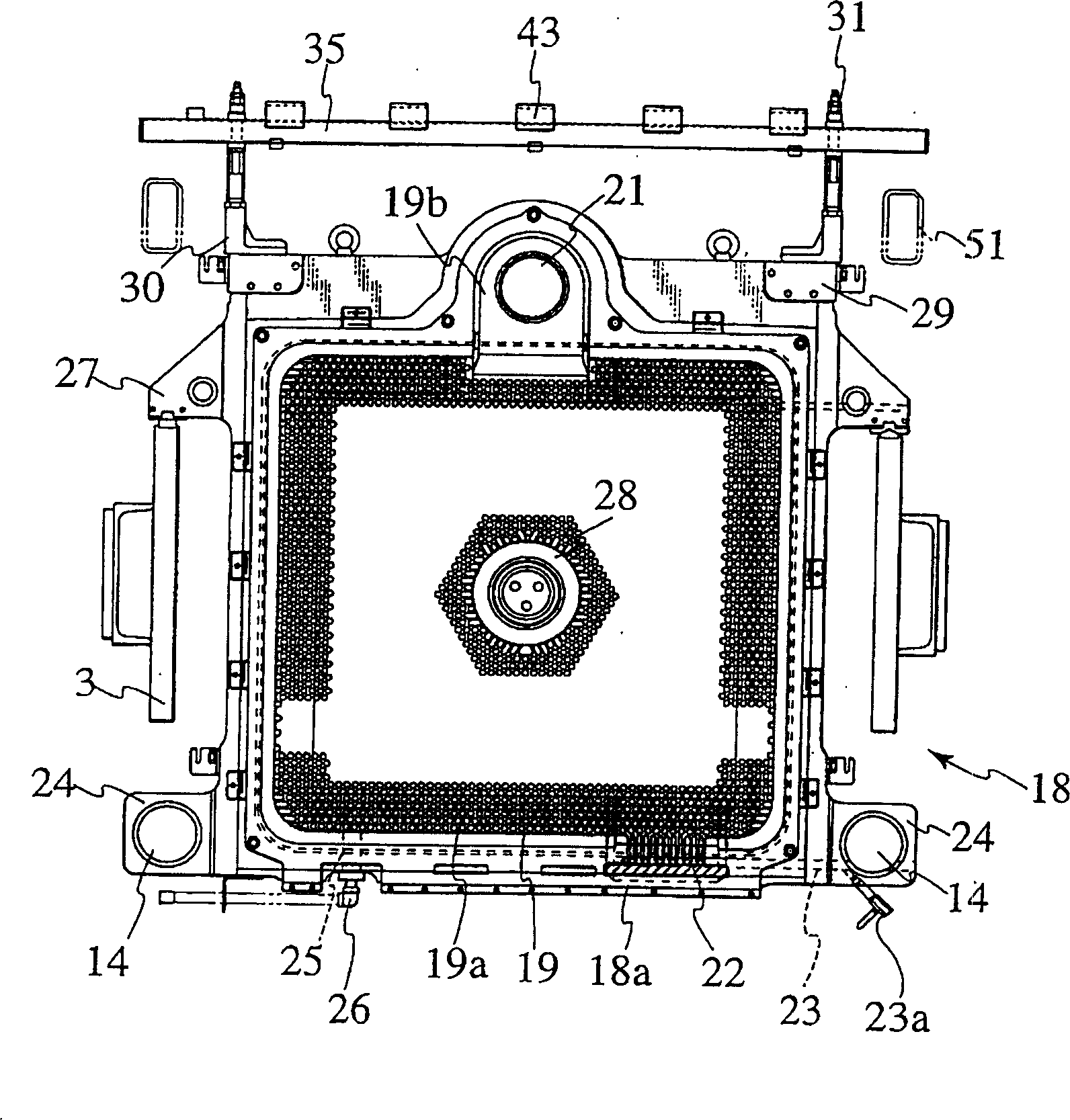

[0023] Hereinafter, embodiments of the filtering device of the filter press according to the present invention will be described in detail with reference to the accompanying drawings.

[0024] like figure 1 As shown, a pair of parallel horizontal guide rails 3 are erected on the front frame 1 and the rear frame 2. In the space between the front frame 1 and the rear frame 2, which are fixed between the left and right side walls, they support many side-by-side rails that can advance separately. And retreated filter plate 4.

[0025] Be positioned at the rear of last filter plate 4, be provided with moving head 5, it is the same with filter plate 4, also is supported on the guide rail 3, can advance and retreat. The moving head 5 is connected to the front end of the piston rod of the clamping cylinder 6 supported on the rear frame 2 , and moves forward and backward along the guide rail 3 by means of the expansion and contraction of the clamping cylinder 6 .

[0026] All side-by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap