Golf ball rod head with a top brace driving panel backing ring

A golf club head and ball panel technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems affecting the golf club's structural integrity and affecting the 20' elastic deformation of the hitting panel. And hitting performance, low elastic deformation ability and other issues, to achieve the effect of improving grip comfort, improving grip comfort, and high elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

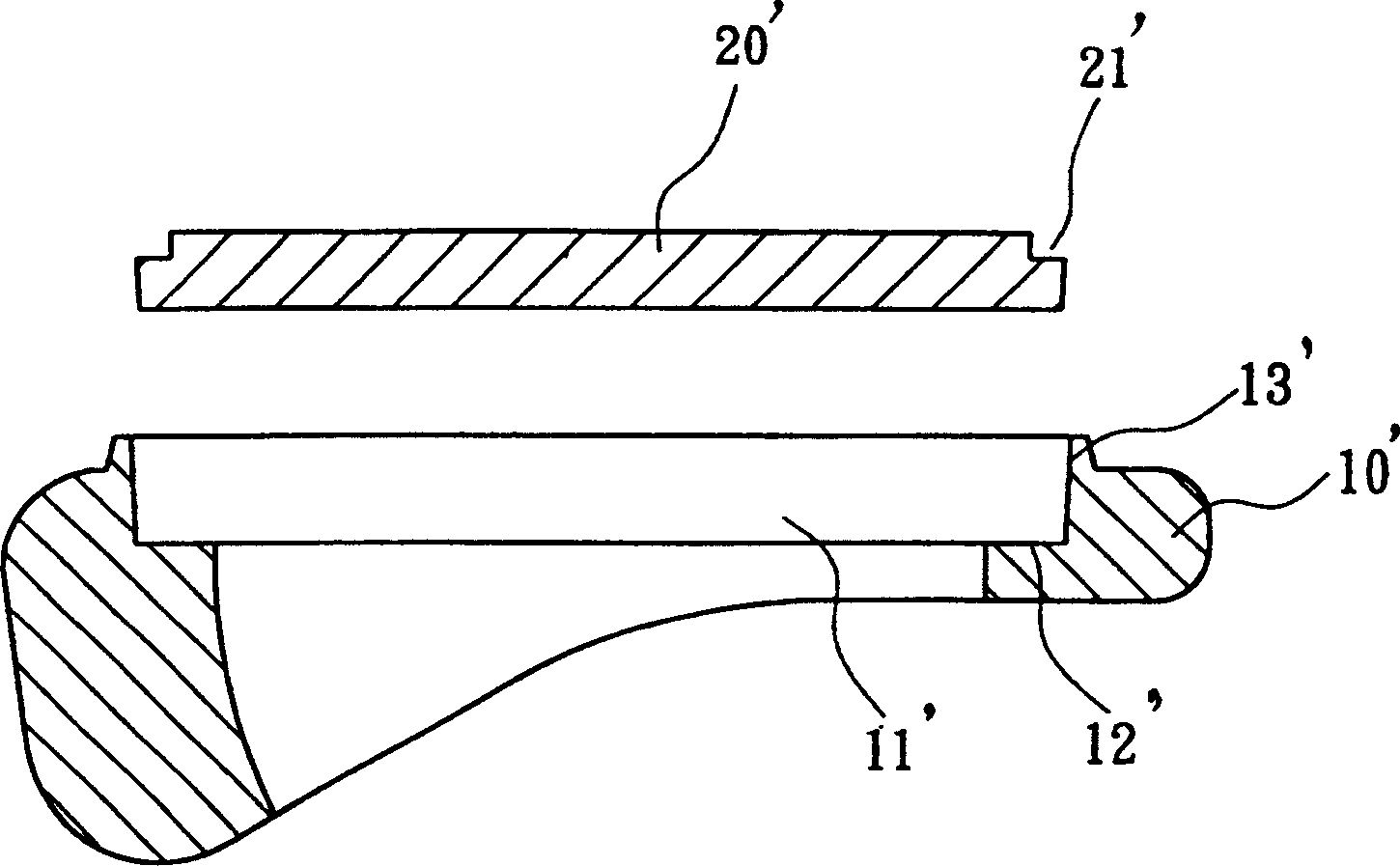

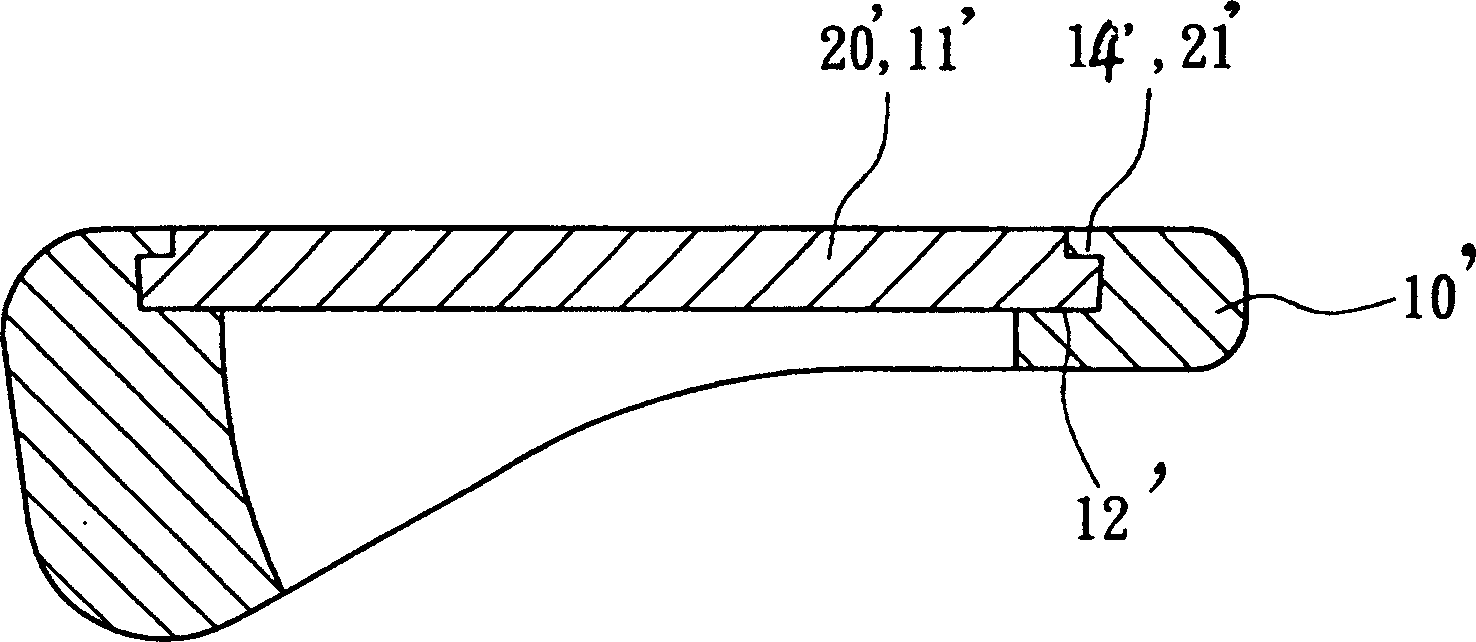

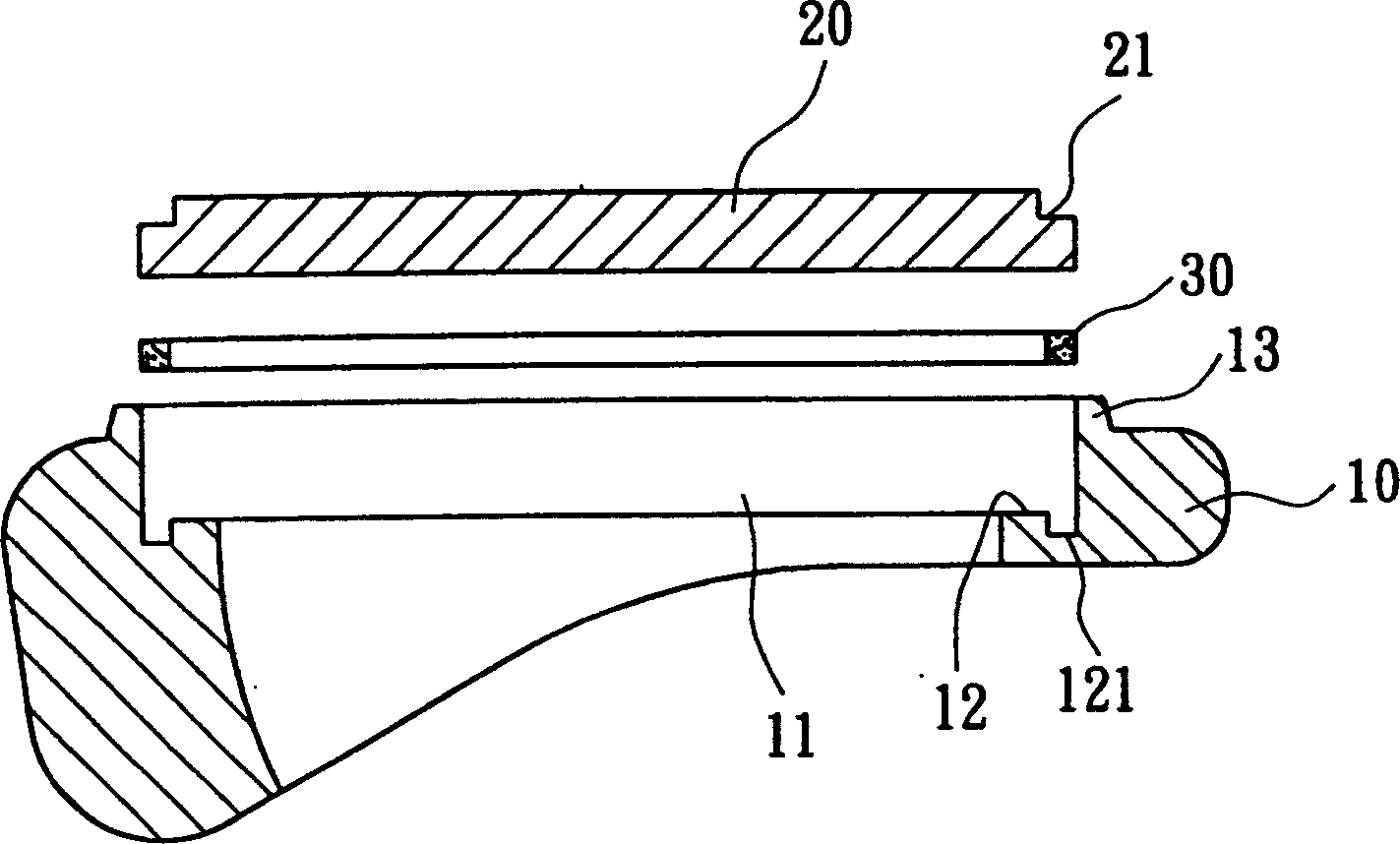

[0033] Such as image 3 , Figure 4 As shown, the present invention includes a club head body 10 , a ball striking faceplate 20 and a washer 30 .

[0034] The 10-series head body consists of Young's modulus higher than 3×10 7 psi stainless steel, carbon steel, alloy steel or iron-manganese-aluminum alloy and other materials, the opening 11 is formed on the front, a shoulder 12 is formed on the inner edge of the opening 11, and an annular groove 121 is formed near the inner wall of the opening 11 on the shoulder 12, and an annular groove 121 is formed on the opening 11. 11 The outer peripheral ring is provided with a feeding flange 13 .

[0035] The batting panel 20 is made of materials such as titanium alloy (such as 6A1-4V Ti alloy), stainless steel (such as SUS174, 350, 455) or special steel (such as 4130 carbon steel). The material of the hitting panel 20 has a lower Young's modulus (less than 3×10) relative to the material system of the club head body 10. 7 psi) and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com