Fine blanking method and device

A technology of fine blanking and punch, which is applied in the field of fine blanking and the fine blanking device that realizes this method, can solve the problems of plastic exhaustion, fine blanking gears that have not been seen, and limit the use range of fine blanking technology, and achieve the goal of increasing the limit thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

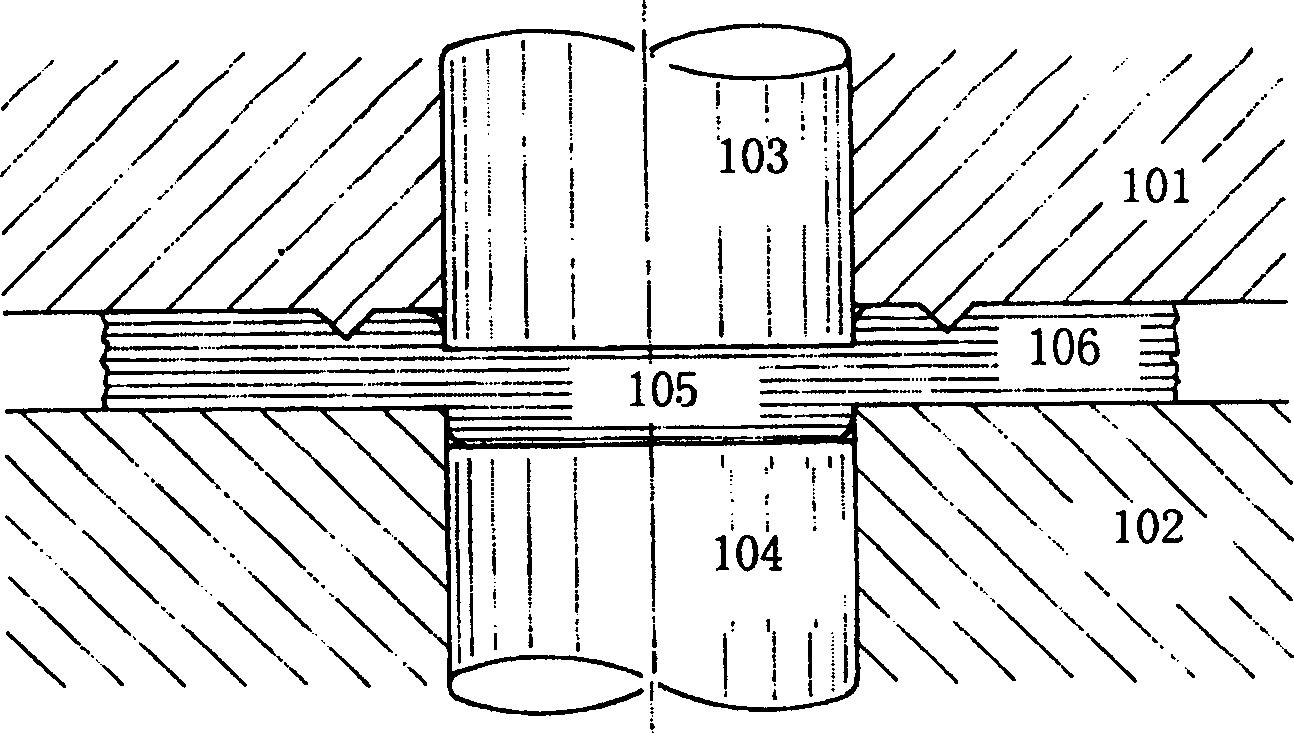

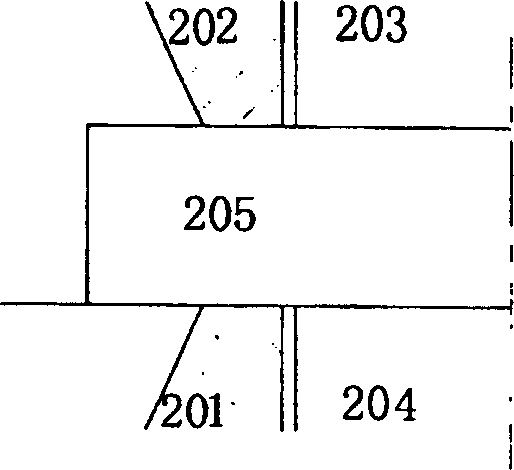

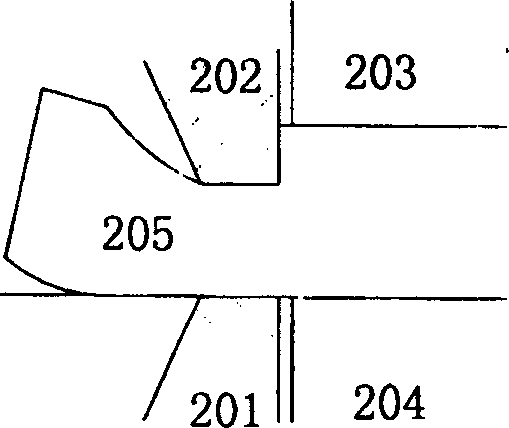

[0020] The fine blanking method of the present invention has three stages, and the schematic diagram of the reciprocating forming fine blanking process is shown in Fig. 2(a), Fig. 2(b), Fig. 2(c) and Fig. 2(d). The reciprocating fine punching die consists of two dies and two punches, as shown in Figure 2(a). The lower die 201 is fixed, and the forming forces of the upper die 202, upper punch 203, and lower punch 204 are individually adjustable, and pressure can be applied according to preset procedures, and three types of locking, high pressure and given pressure can be realized. state. In the first stage of forming, the lower punch 204 and the upper die 202 are locked, the upper punch 203 is at zero pressure, the upper die 202 moves downward, and the material of the blank 205 flows into the upper die cavity, as shown in Figure 2(b) . In the second stage of forming, the upper die 202 and the upper punch 203 are locked, the lower punch 204 has zero pressure, and the blank mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com