Differential pressure type sprayer

A spraying device and pressure difference technology, which is applied in spraying devices, liquid spraying devices, fire rescue, etc., can solve the problems of limited effective spraying area and slow response time, and achieve the effect of increasing the effective spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] In order to make the above-mentioned features, methods, purposes and advantages of the present invention more obvious and easy to understand, in conjunction with the accompanying drawings, it is described as follows:

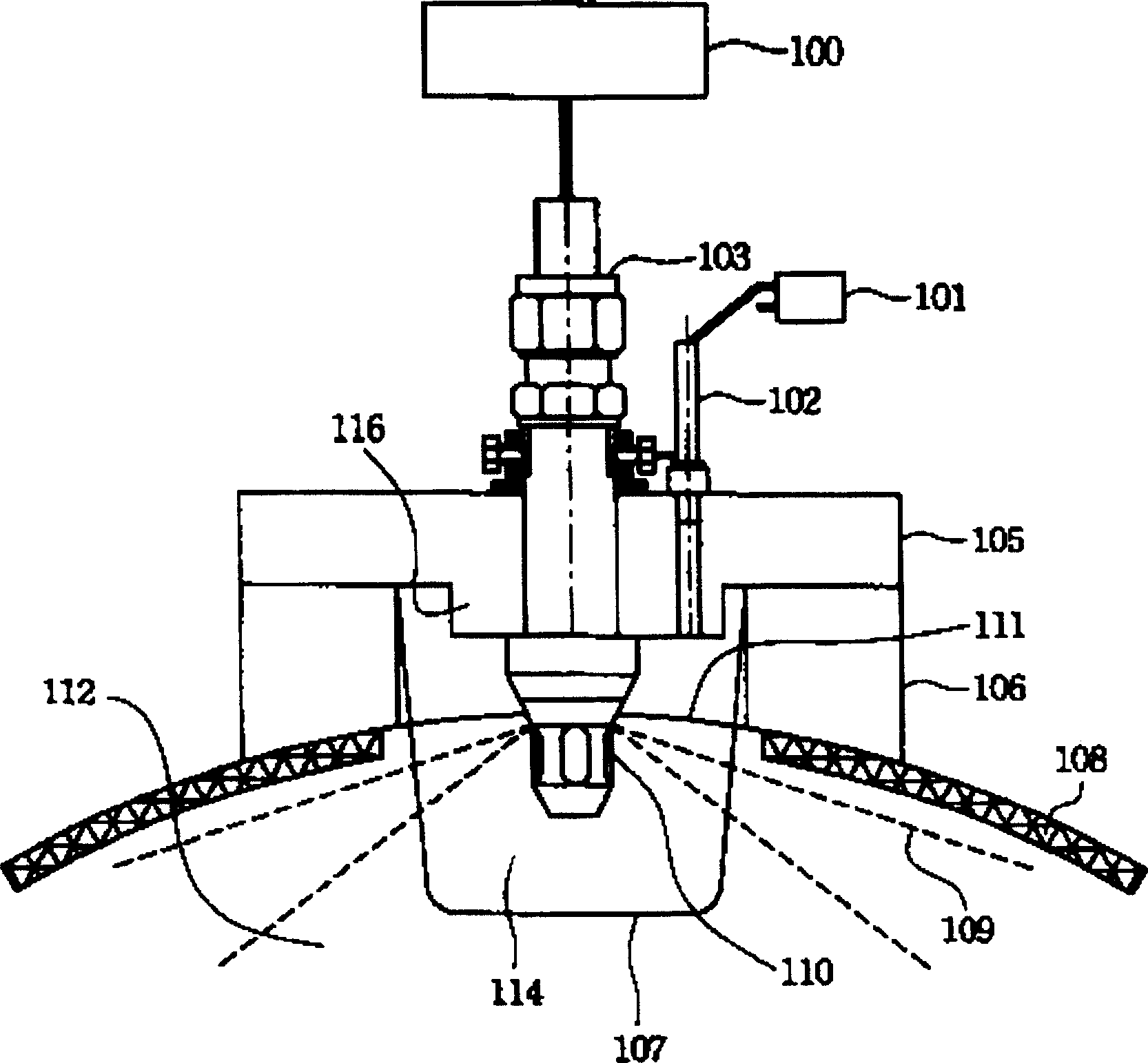

[0025] figure 1 A cross-sectional view of a preferred embodiment of a sprinkler using a differential pressure switch provided by the present invention is shown.

[0026] The spraying device of the present invention includes a differential pressure switch 101 , a pressure sensing component 102 , a spraying element 103 , an upper cover 105 , a base 106 and an airtight bag 107 . Wherein, the spraying element 103 is fixed in the upper cover 105 and externally connected to the material supply device 100 for supplying the spraying material 109 . In addition, the spraying element 103 also includes a spraying head 110 as an outlet for the spraying material 109 .

[0027] The spraying device of the present invention is connected on the air duct wall 108 of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com