Textile processing system and textile processing machine

A fabric processing and processing machine technology, applied in the field of yarn reel dyeing machines, can solve the problems of inability to produce uniform dyeing effect of samples, uneconomical and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

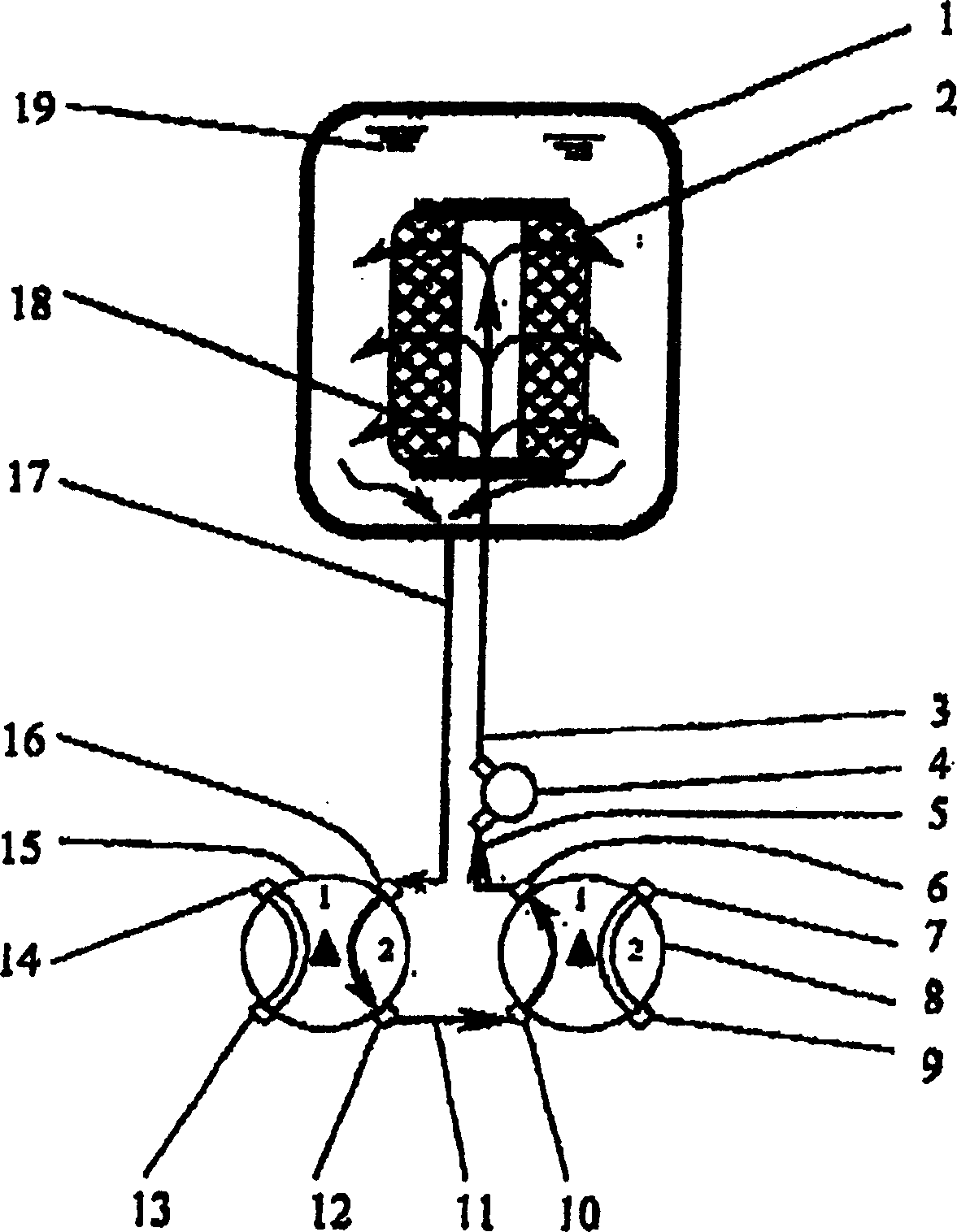

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings: please refer to figure 1 , The basic operation of the yarn dyeing machine requires dyeing in the machine to cycle from the inside to the outside and from the outside to the inside through the yarn. figure 1 The dye liquor circulating from the inside of the yarn roll 2 to the outside 18 is shown. Although the roll 2 includes yarn wrapped around a dyeing tube, the roll may include fabric wrapped around a dyeing tube.

[0025] figure 1 The yarn roll dyeing machine includes a container 1, a pipeline system 3, 5, 11, 17, a circulating pump 4, and two valves 8, 15.

[0026] The two valves 8, 15 each include a body with four ports 6, 7, 9, 10, 12, 13, 14, 16 and a connecting device.

[0027] in figure 1 In the illustrated embodiment, the valves 8, 15 are connected in the piping systems 3, 5, 11, 17 so that the machine is set to work independently. When the yarn roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com