Cutting insert for grooving

A technology for cutting blades and blades, which is applied in the direction of cutting tools, forming knives, turning equipment, etc. for lathes, and can solve problems such as machine interruption and shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Detailed description of the preferred embodiment

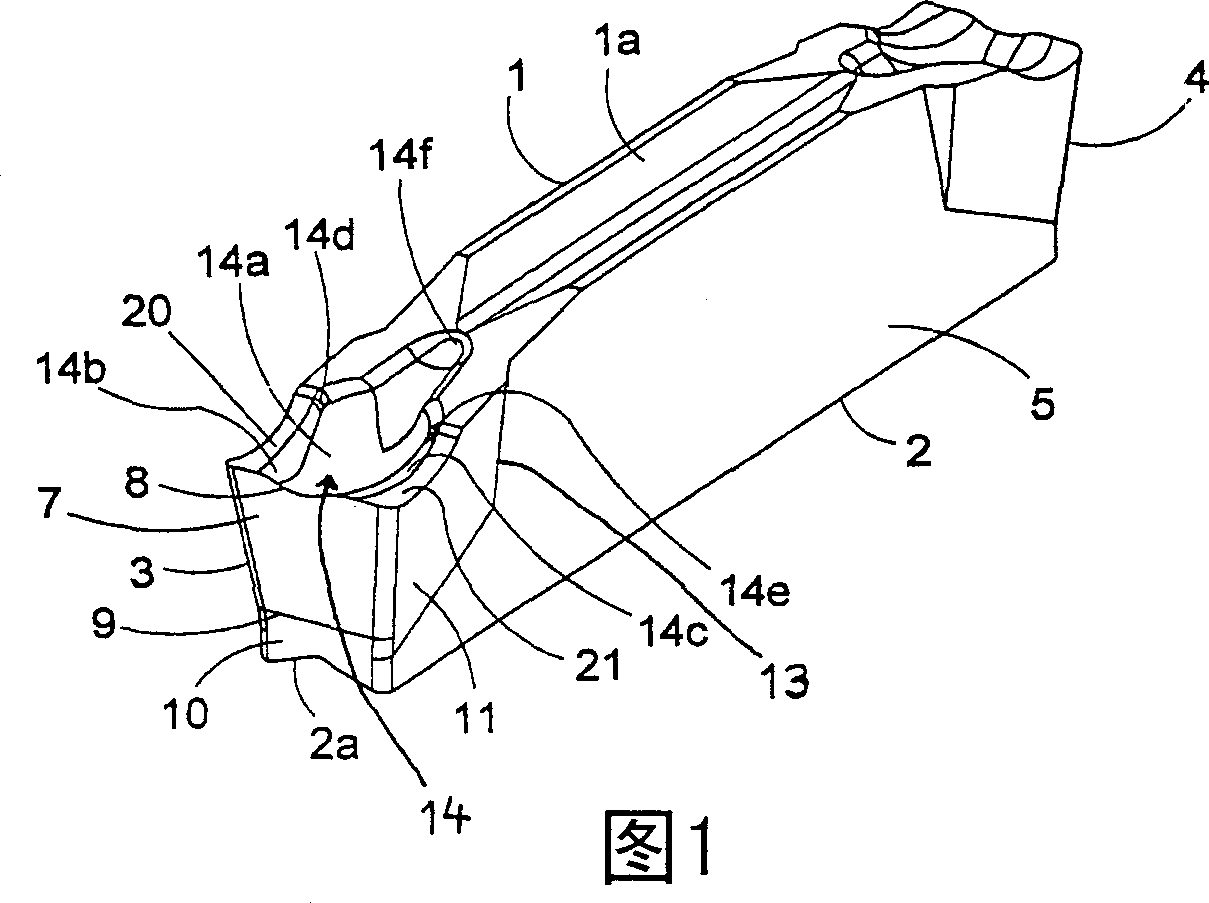

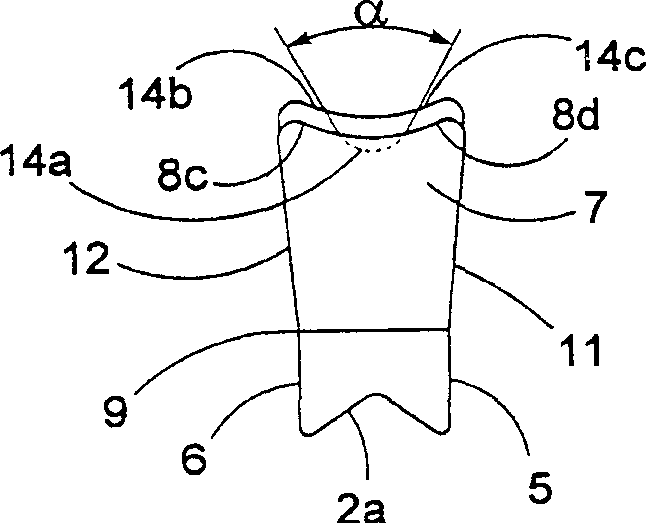

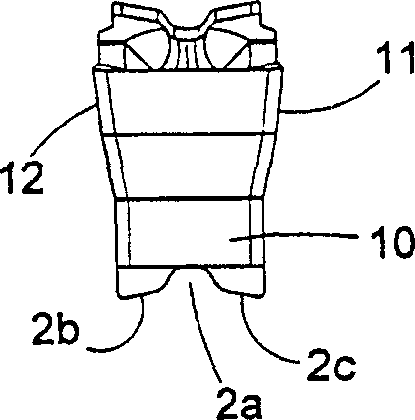

[0017] Figures 1-3 show a cutting insert for grooving according to the invention comprising a parallelepiped-shaped body having an upper surface 1, a lower surface 2, a front end surface 3, a rear end surface 4 and two opposite parallel sides 5,6. The cutting insert may or may not be coated with a carburized layer; the upper surface 1 and the lower surface 2 are respectively formed with a longitudinal concave V-shaped key groove 1a and 2a. Alternatively, cutting inserts can be Figure 2b The embodiment shown, wherein the lower support surfaces 2b, 2c have an inclination on each side of the central groove 2a, and are used in a blade-shaped tool holder in the manner described in Swedish Patent Application No. 9703434-2 Supporting corresponding inclined support surfaces, the content of said Swedish patent application No. 9703434-2 is hereby incorporated by reference. The central portion of the cutting insert is a shank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com