Method for thermally treating substrates

A heat treatment method and heat treatment process technology, applied in the field of heat treatment of substrates, can solve problems such as unforeseen temperature and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

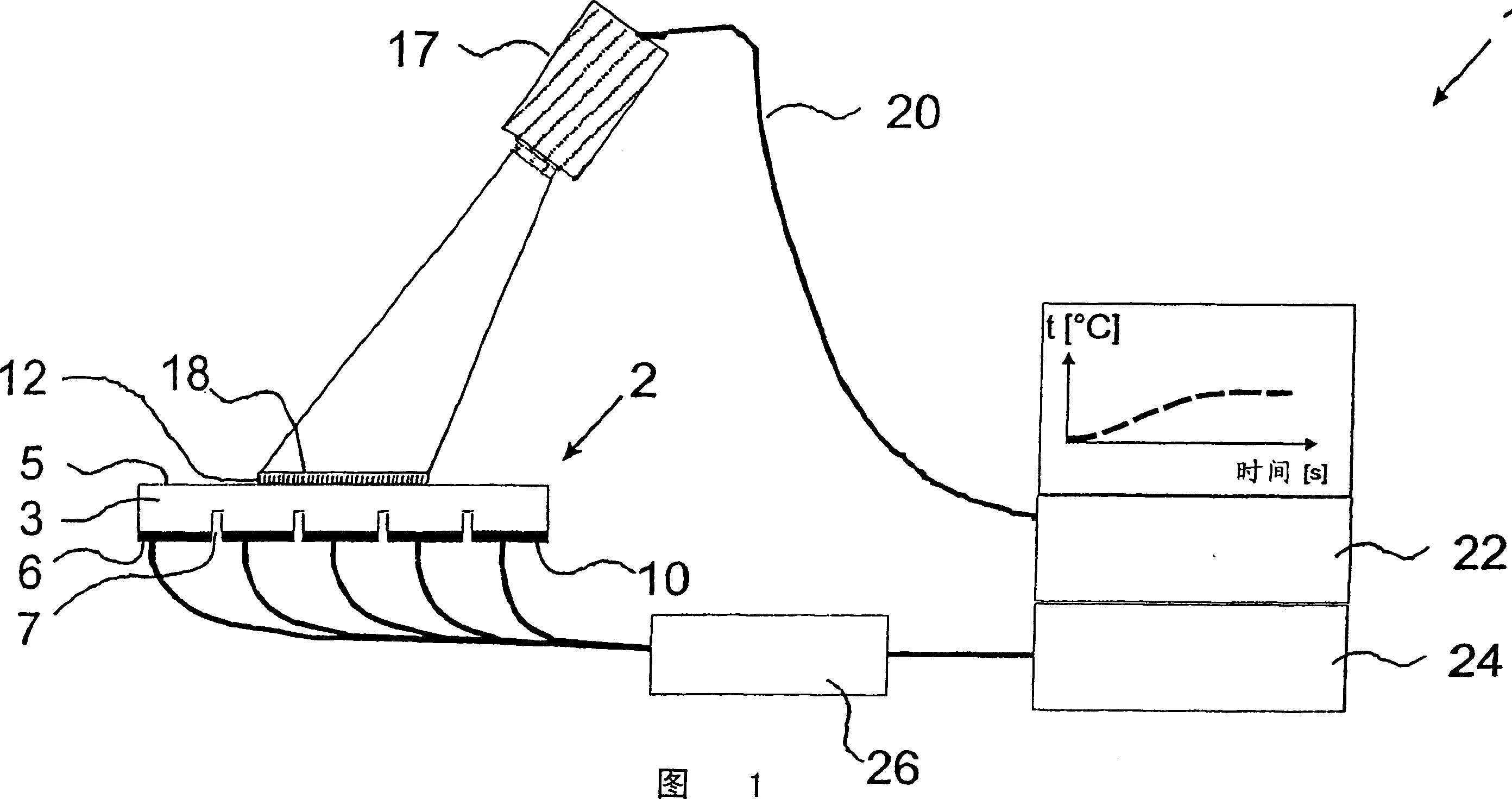

[0024] FIG. 1 is a schematic side view of a substrate heat treatment apparatus 1 .

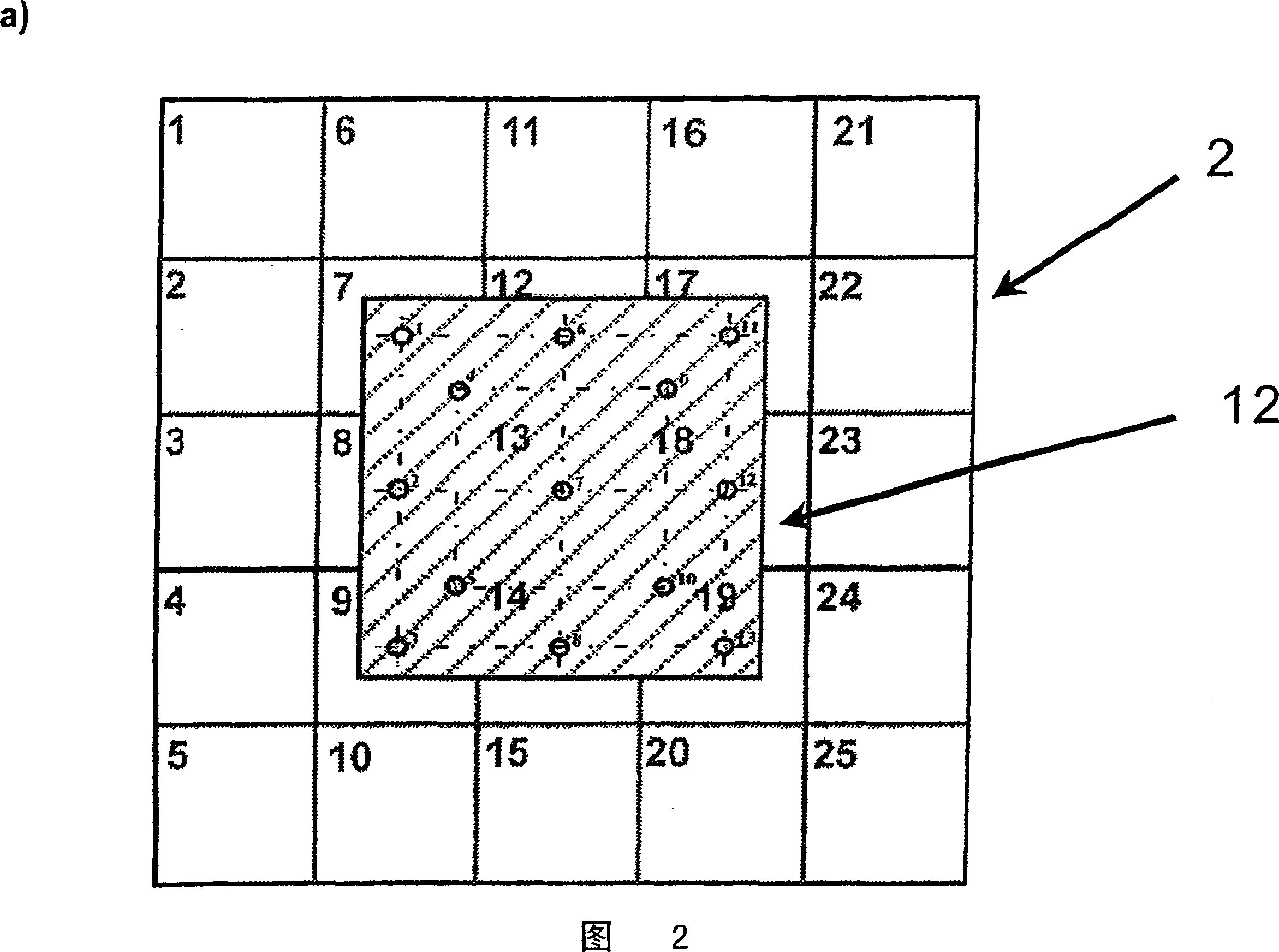

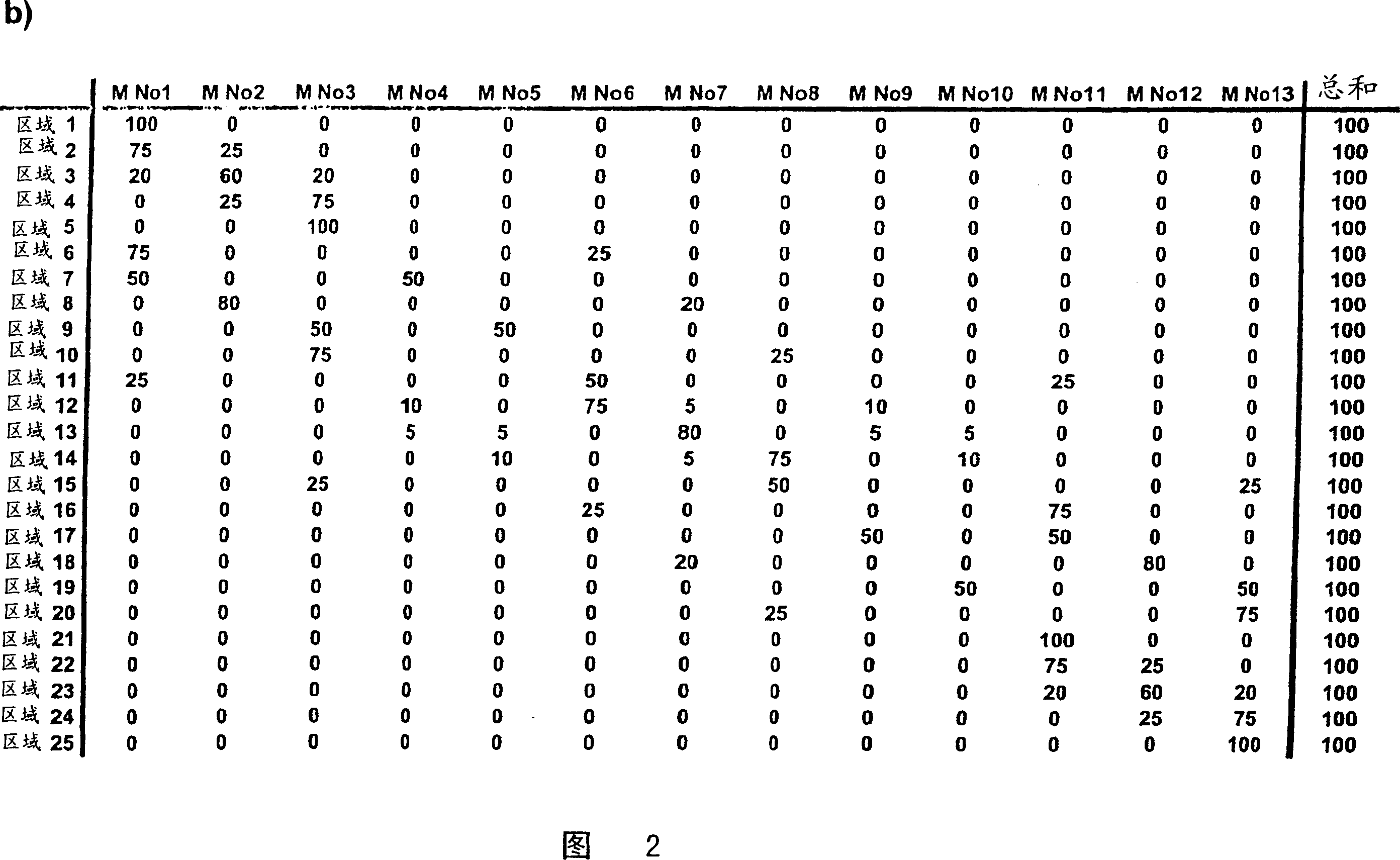

[0025] The device 1 has a zone-controlled heating plate 2 consisting of a square base plate 3 with an approximately rectangular cross-section. The base plate 3 has a first planar top surface 5 and a segmented bottom surface 6 . The bottom surface 6 is divided into a total of 25 square regions 8 by four grooves 7 running perpendicularly to the sides of the heating plate. The depth of the groove 7 is approximately equal to half the thickness of the bottom plate 3 . On the square regions 8 of the heating plate 2 there are in each case square heating elements 10 which are suitably connected to the regions 8 of the base plate 3 , for example by gluing, and which together form the corresponding heating zones. By arranging the heating elements 10 on the regions 8 which are each separated by the slots 7 , these heating elements are thermally isolated from each other so that they do not influence eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com