Optical-head apparatus

A technology of optical head and light source, which is applied in the direction of integrated optical head device, beam guiding device, optical recording head, etc., which can solve the problems of high manufacturing cost, low sealing performance and rough bonding surface of metal molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment to which the optical head apparatus of the present invention is applied will be described below with reference to the accompanying drawings.

[0027] (overall composition)

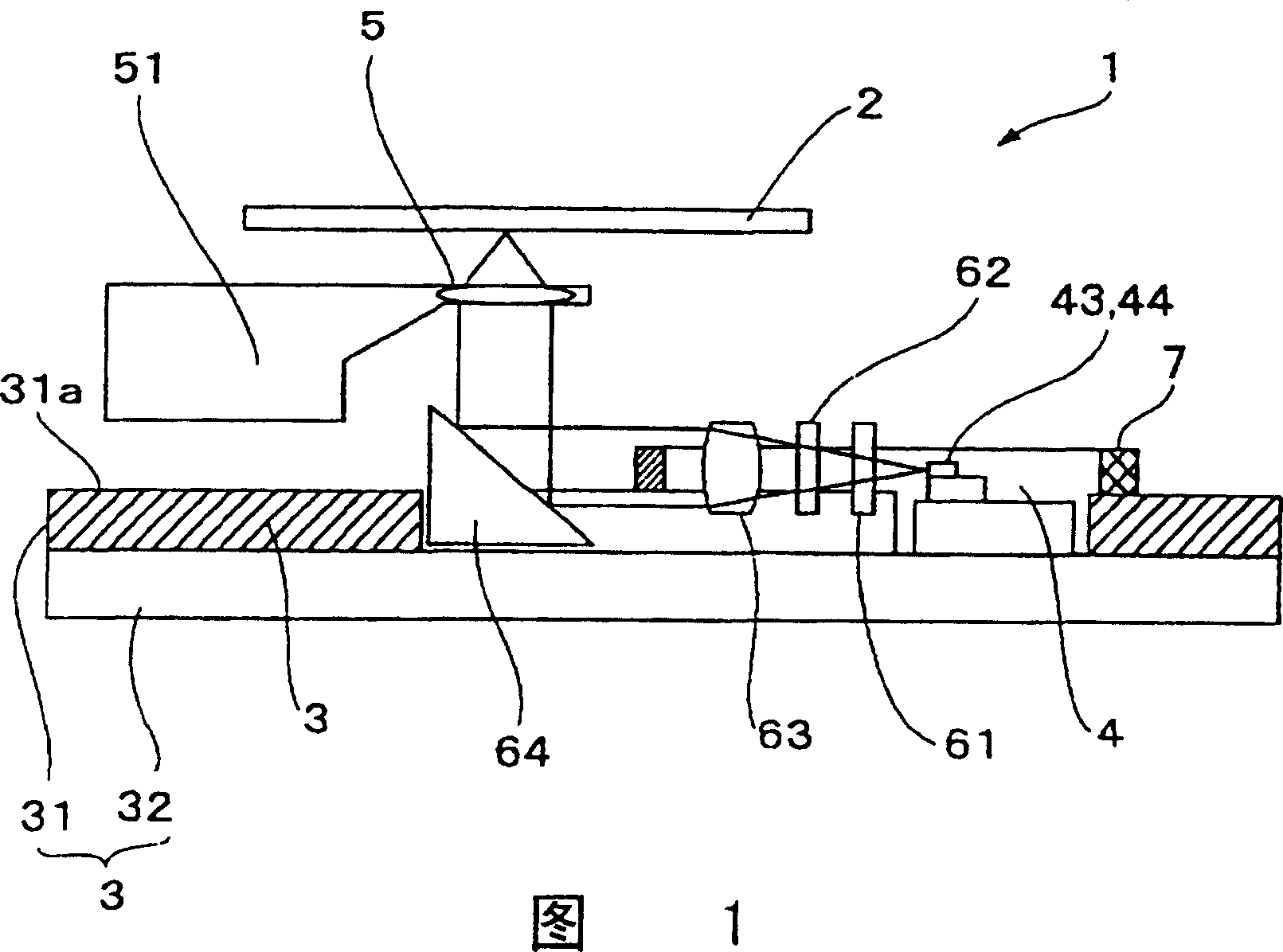

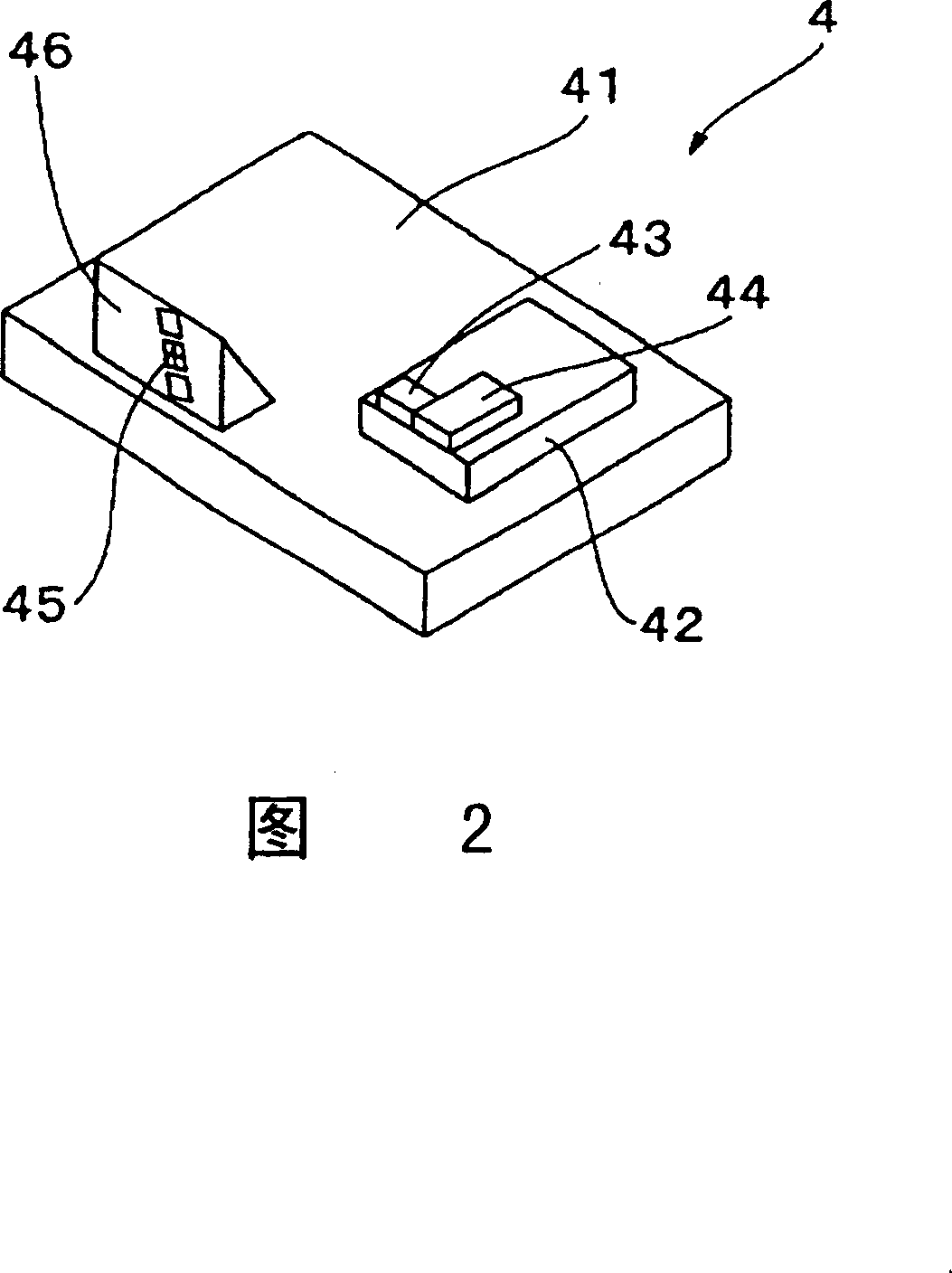

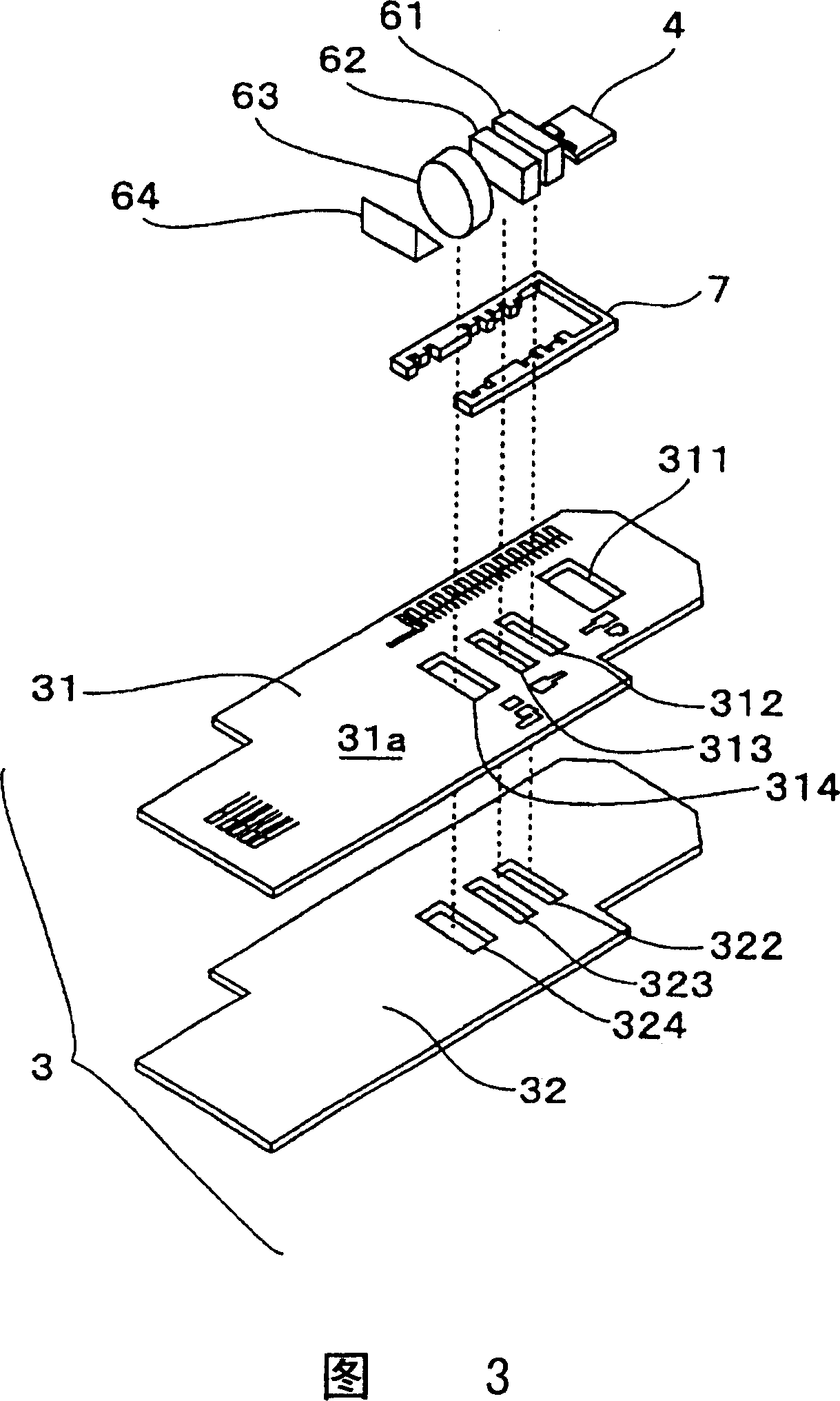

[0028] FIG. 1 is a cross-sectional view showing the optical head device of the present invention, and FIG. 2 is a perspective view showing a light-receiving and light-emitting element in the optical head device in FIG. 1 . Description will now be made with reference to these figures. The optical head device 1 of the present embodiment is a two-wavelength optical head device for recording and reproducing information on an optical recording medium 2 such as CD or DVD, and using a laser beam with a wavelength of 650 nm and a laser beam with a wavelength of 780 nm. Various components are mounted on the base 3 composed of a circuit board 31 made of metal such as aluminum and a base frame 32 made of metal stacked on top of each other.

[0029] The base 3 is provided with a main shaft that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com