Combined type valve with double fluid channels in use for reciprocating pump

A reciprocating pump, dual-flow technology, used in control valves, valve devices, pump components, etc., can solve the problems of small flow area, short valve plate life, and difficulty in exhausting gas, so as to increase the flow area, reduce Valve closing acceleration and impact force, the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

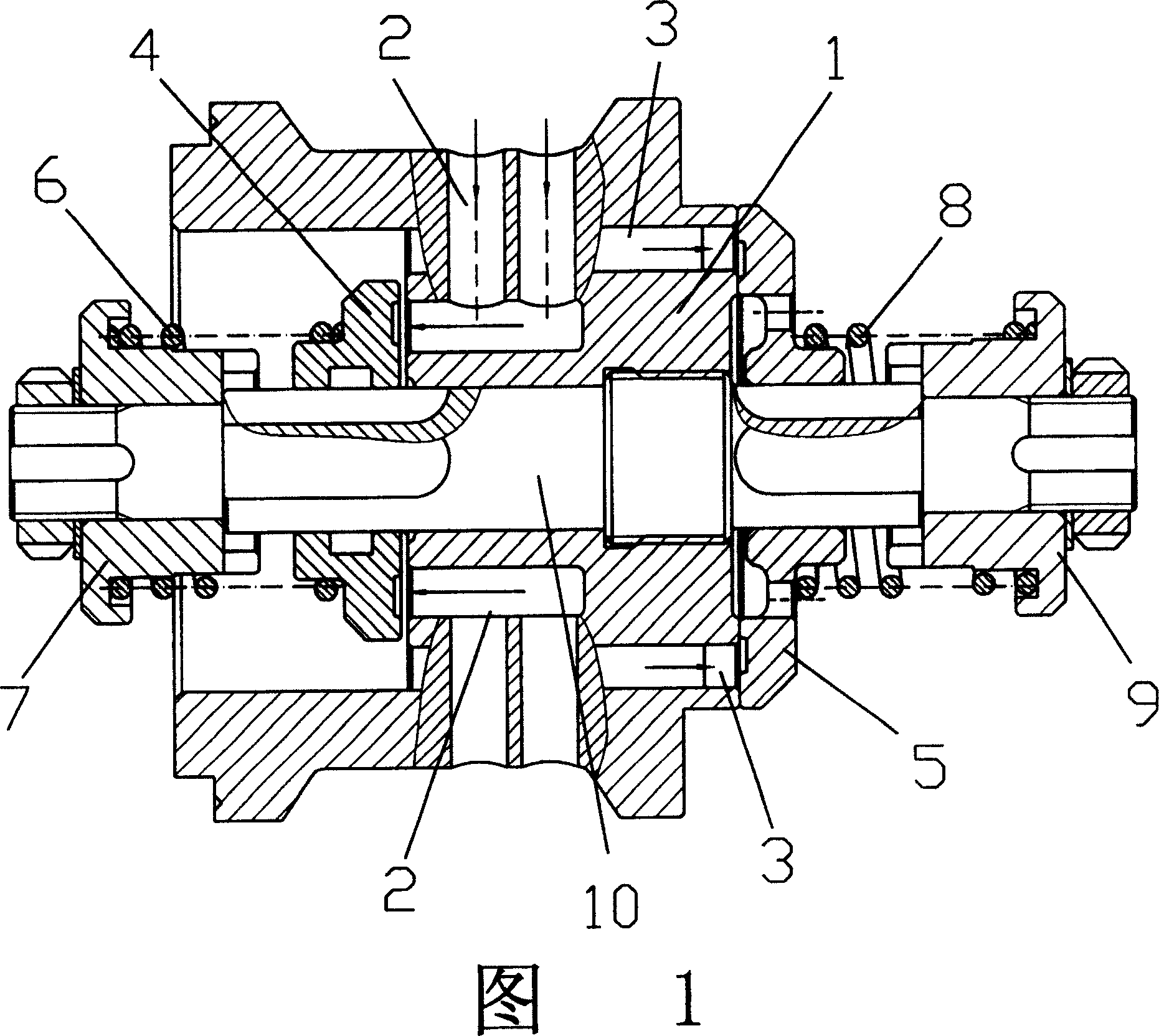

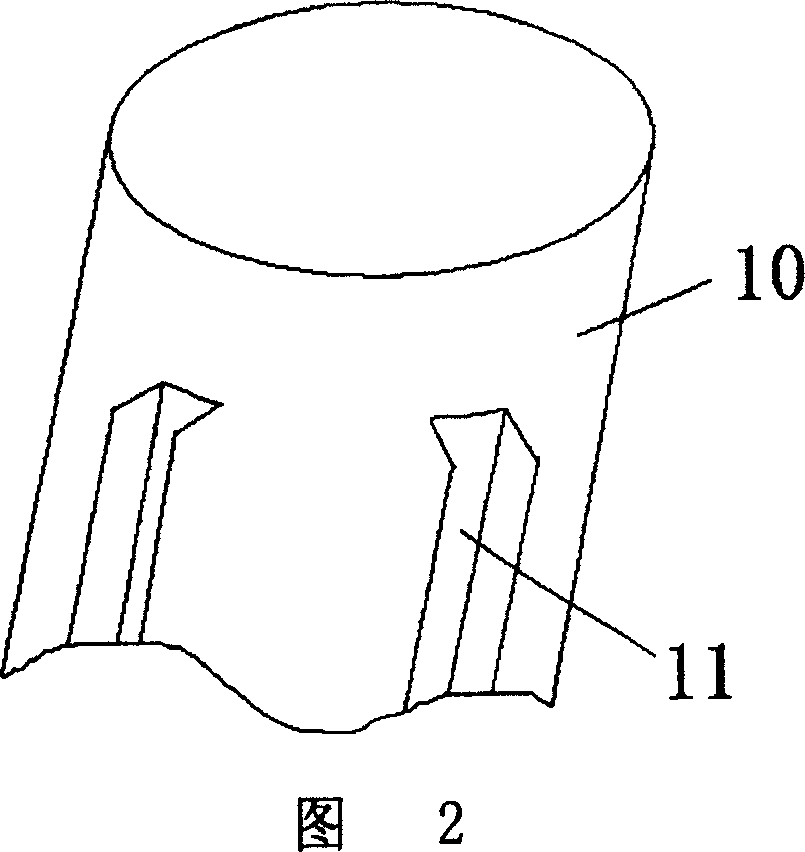

[0018] Referring to Fig. 1 and Fig. 2, a dual-channel combination valve for a reciprocating pump includes a valve body 1, and the valve body is provided with an inlet valve flow channel 2 communicating with the inlet of the reciprocating pump and a channel communicating with the outlet of the reciprocating pump. Outlet valve channel 3, the outlet of the inlet valve channel 2 is equipped with an inlet valve plate 4 for opening and closing the inlet valve channel, and the outlet of the outlet valve channel 3 is equipped with an inlet valve plate 4 for opening and closing the inlet valve channel. Close the outlet valve plate 5 of the outlet valve flow channel, the inlet valve plate 4 is connected with the inlet spring seat 7 through the inlet spring 6, the space in front of the inlet valve plate 4 is a reciprocating medium cavity, and the outlet valve plate 5 The outlet spring 8 is connected to the outlet spring seat 9, the space in front of the outlet valve plate 5 is a reciproca...

Embodiment 2

[0022] Referring to FIG. 1 , the inflow and outflow ports of the outlet valve channel 3 are located outside the outflow port of the inlet valve channel 2 , so that the gas in the pump cylinder can be exhausted. Especially when the outlet valve channel 3 is located at the outermost side of the valve body 1, the effect is better.

[0023] The rest of the structure and implementation are the same as in Embodiment 1.

Embodiment 3

[0025] The inlet spring seat and the outlet spring seat are also provided with flow passages to further increase the flow area. The axial groove, of course, the structure and shape of the flow channels on the inlet spring seat and the outlet spring seat are not limited thereto.

[0026] The rest of the structure and implementation are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com