Method for processing photographic material

A photographic material and processing liquid technology, which is applied in the direction of photosensitive material, circulating liquid processing, silver salt photosensitive material technology, etc., and can solve problems such as uneven processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This is an embodiment of the present invention.

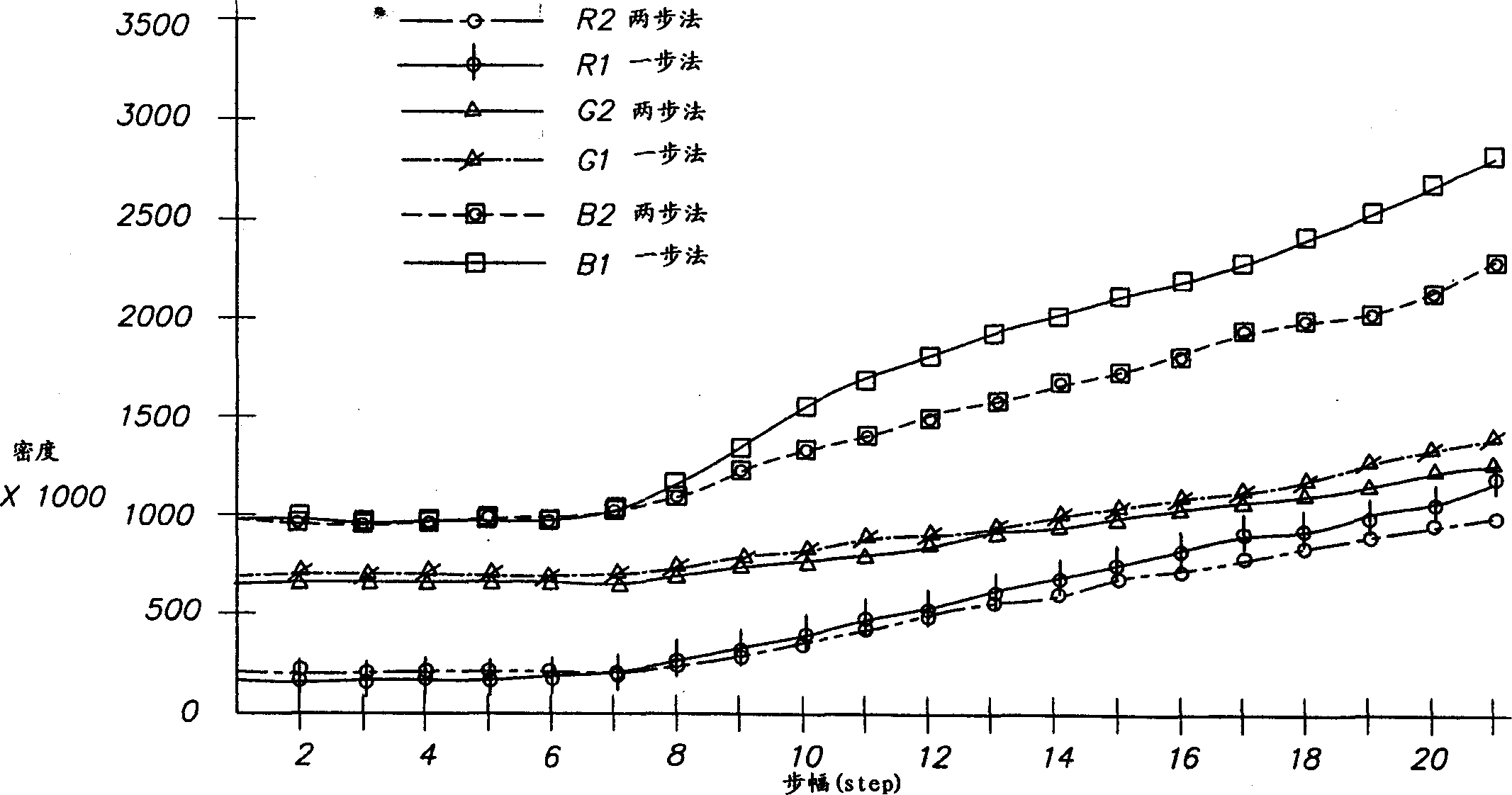

[0036] Table 1 compares two processing cycles, one of which has a one-step solution development phase and the other a two-step solution process. All remaining stages of the cycle are identical and are standard C-41 methods.

[0037] Table 1 Two-step development method and one-step development method

[0038] Treatment 1 Treatment 2

[0039] Phase Part 1 Part 2 One step

[0040] Develop 5 seconds 25 seconds 30 seconds

[0041] Stop display for 30 seconds - 30 seconds

[0042] Bleach 3 minutes 30 seconds - 3 minutes 30 seconds

[0043] Fixing 3 minutes 30 seconds - 3 minutes 30 seconds

[0044] Wash 2 minutes - 2 minutes

[0045] Wherein the bleach solution is Kodak Flexicolor Bleach Solution III NR, the fixer is Kodak Flexicolor fixer, and the supplement and stop solution are 10% acetic acid. Shown in Table 2 are the compositions of the one-step solution and the compositions of th...

Embodiment 2

[0083] This is yet another embodiment of the present invention.

[0084] The developers in Table 5 were made as a whole section.

[0085] Table 5 Developer solution composition

[0086] Component Concentration

[0087] Na 3 PO 4 .12H 2 O 50 g / L

[0088] DEHA 5ml / L

[0089] KBr 8 g / L

[0090] Na 2 SO 3 2 g / l

[0091] CD4 10 g / L

[0092] Tween 80 10 drops / liter

[0093] pH 12.0

[0094] The developer was used at a rate of 14 ml / longitudinal foot of 35 mm film in the processing cycle shown in Table 6.

[0095] Table 6 Processing cycle

[0096] Develop 30 seconds 14ml / longitudinal foot 35mm film

[0097] Stop 20 seconds 4ml / longitudinal foot 35mm film

[0098] Bleach 3 minutes 30 seconds Large tank (2 liters)

[0099] Fixing 3 minutes 30 seconds Large tank (2 liters)

[0100] wash 2 minutes

[0101] Wherein the developer stop agent is 10% acetic acid, the bleaching solution is Kodak Flexicolor bleaching solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com