Multi-blade coater

A coating machine, multi-knife technology, applied in the device, coating, textile and paper making of the surface coating liquid, etc., can solve the problems of poor coating effect and different thickness of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

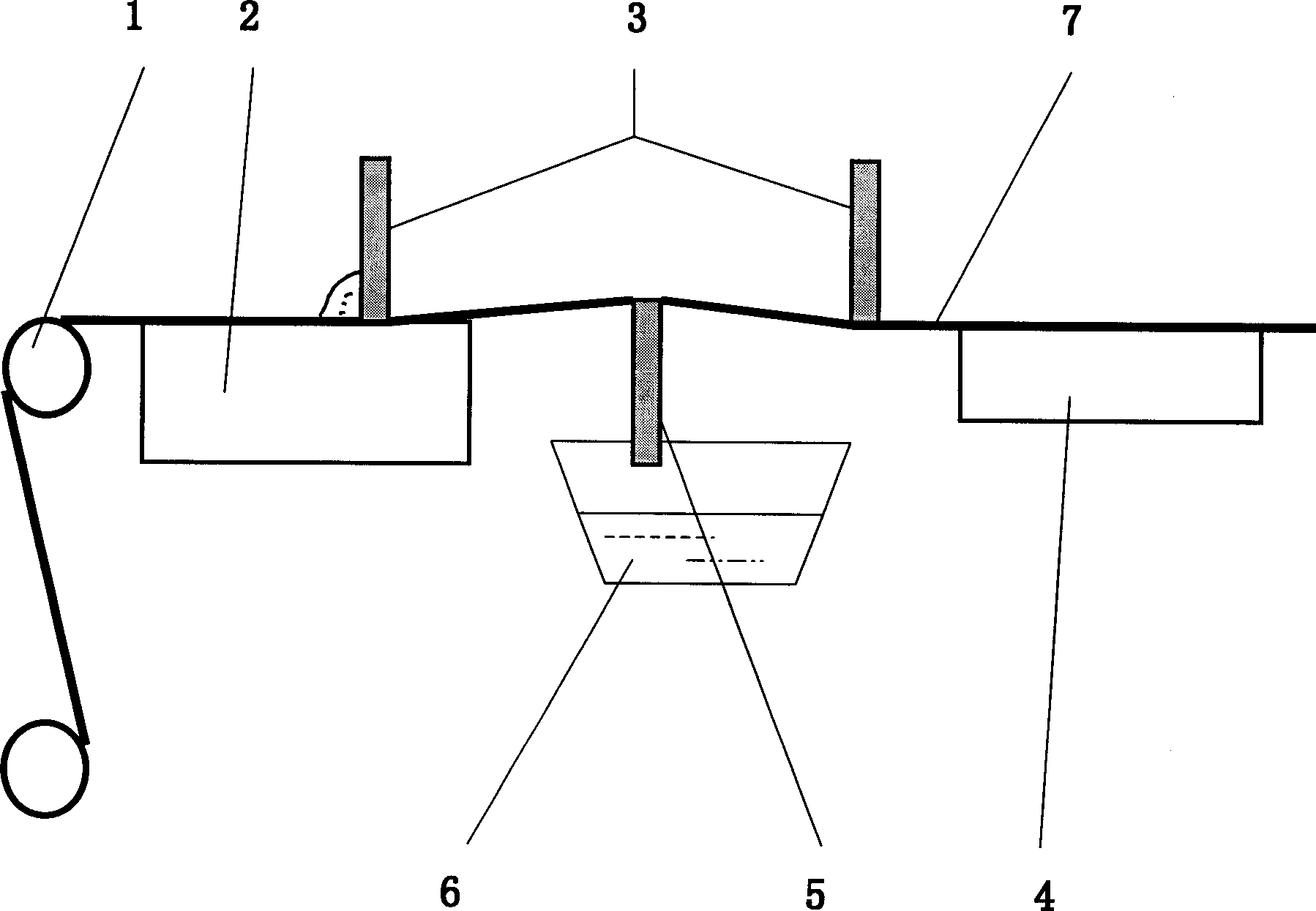

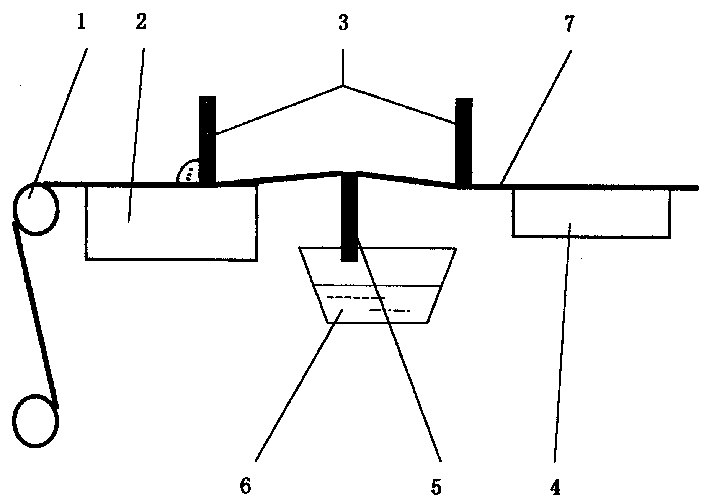

[0006] The present invention includes a cylinder 1, a platform 2, an upper scraper 3 and a fabric pulling device 4, etc., wherein the needle plate pulling device 4 can pull the fabric to pass between the platform 2 and the upper scraper 3, and is characterized in that: the upper scraper 3 Back scraper 5 is equipped with, and lower scraper 5 is positioned at the below of fabric 7, and the coating that seeps through fabric 7 is scraped evenly. A receiving hopper 6 is installed below the lower scraper 5 to receive the coating scraped by the lower scraper 5 . Described fabric pulling device 4 is generally needle plate pulling device. In actual coating, in order to obtain a good coating effect, one or more upper scrapers and lower scrapers can be installed according to the characteristics of the coating and the coating situation. Generally, the upper and lower scrapers are installed alternately in groups to compare the effect Well, that is, one upper scraper and one lower scraper ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap