Electromagnetic valve solenoid

A solenoid, solenoid valve technology, applied in the direction of electromagnets, electromagnets with armatures, circuits, etc., can solve the problems of troublesome and large installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

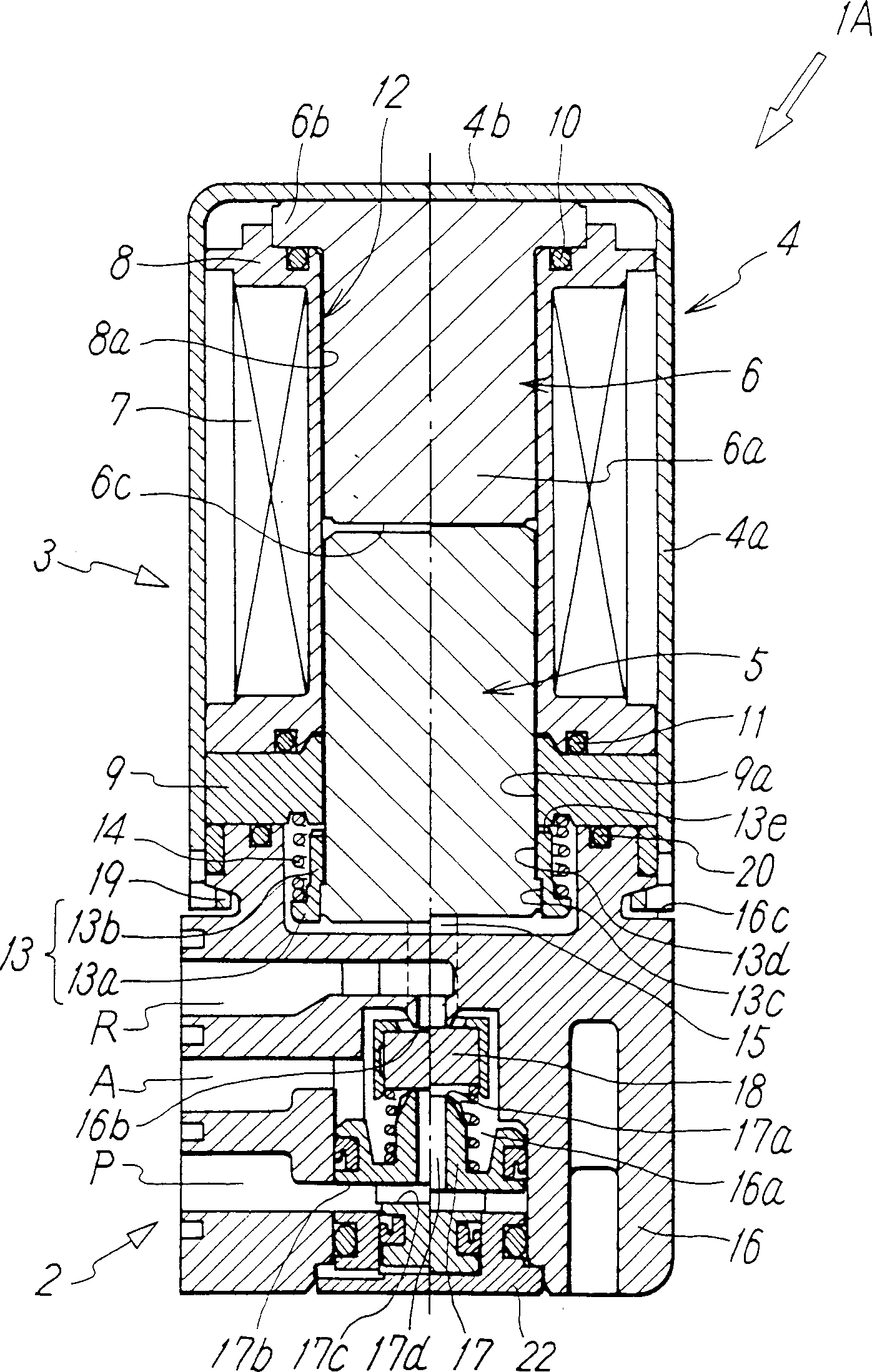

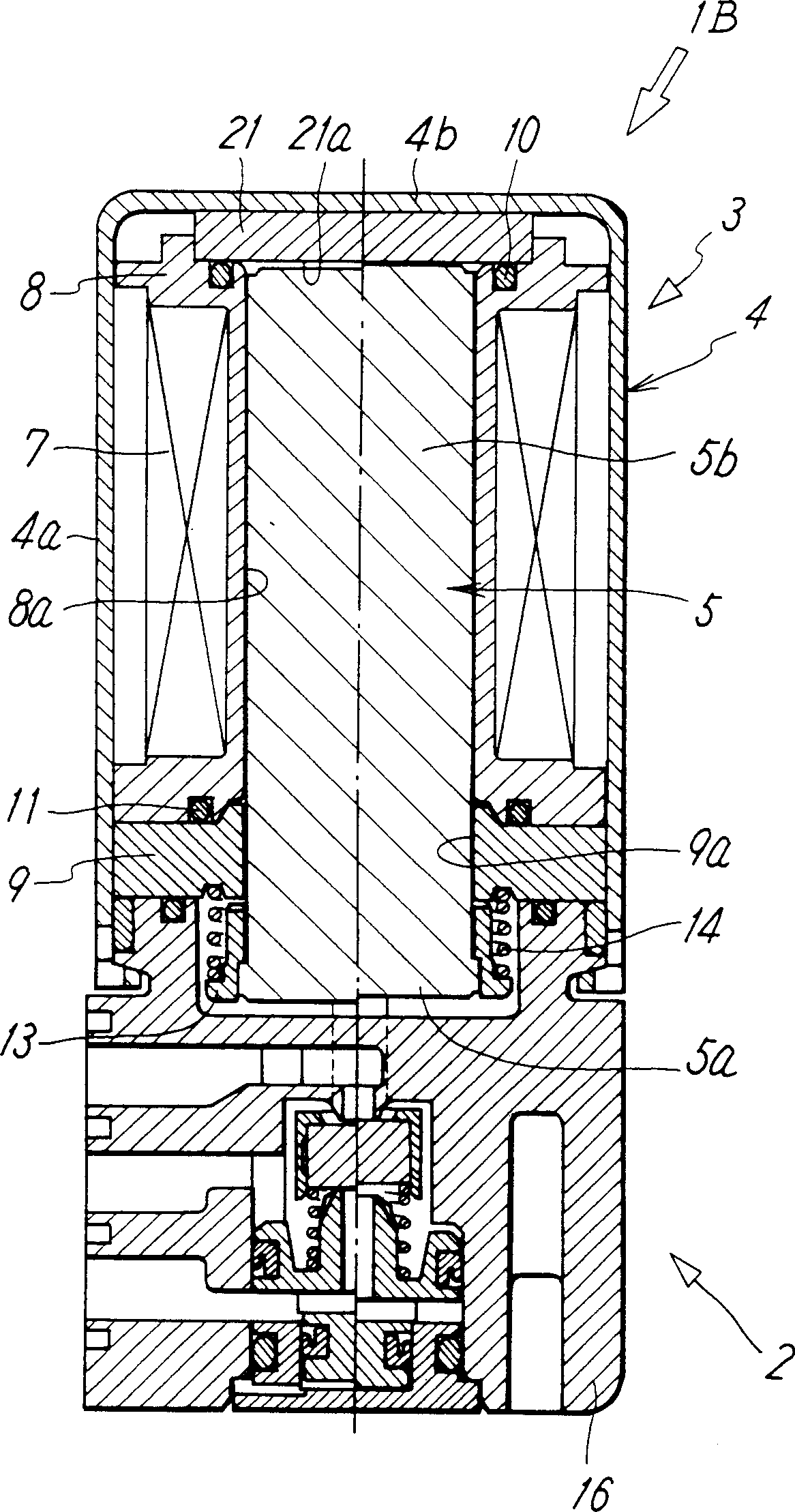

[0020] figure 1 The first embodiment of the present invention is shown, and a case where a solenoid valve solenoid is applied to a 3-port solenoid valve is shown. This solenoid valve 1A has a valve portion 2 in which a valve member 18 for switching a flow path is mounted, and the solenoid 3 that drives the valve member 18 .

[0021] The solenoid 3 includes a magnetic case 4 . The magnetic case 4 is composed of a cylindrical wall portion 4a having a substantially rectangular cross-sectional shape and an end wall portion 4b that closes one end side of the cylindrical wall portion 4a in the axial direction. The end of the valve skeleton 16 of the above-mentioned valve part 2 is fitted on the end of the opening.

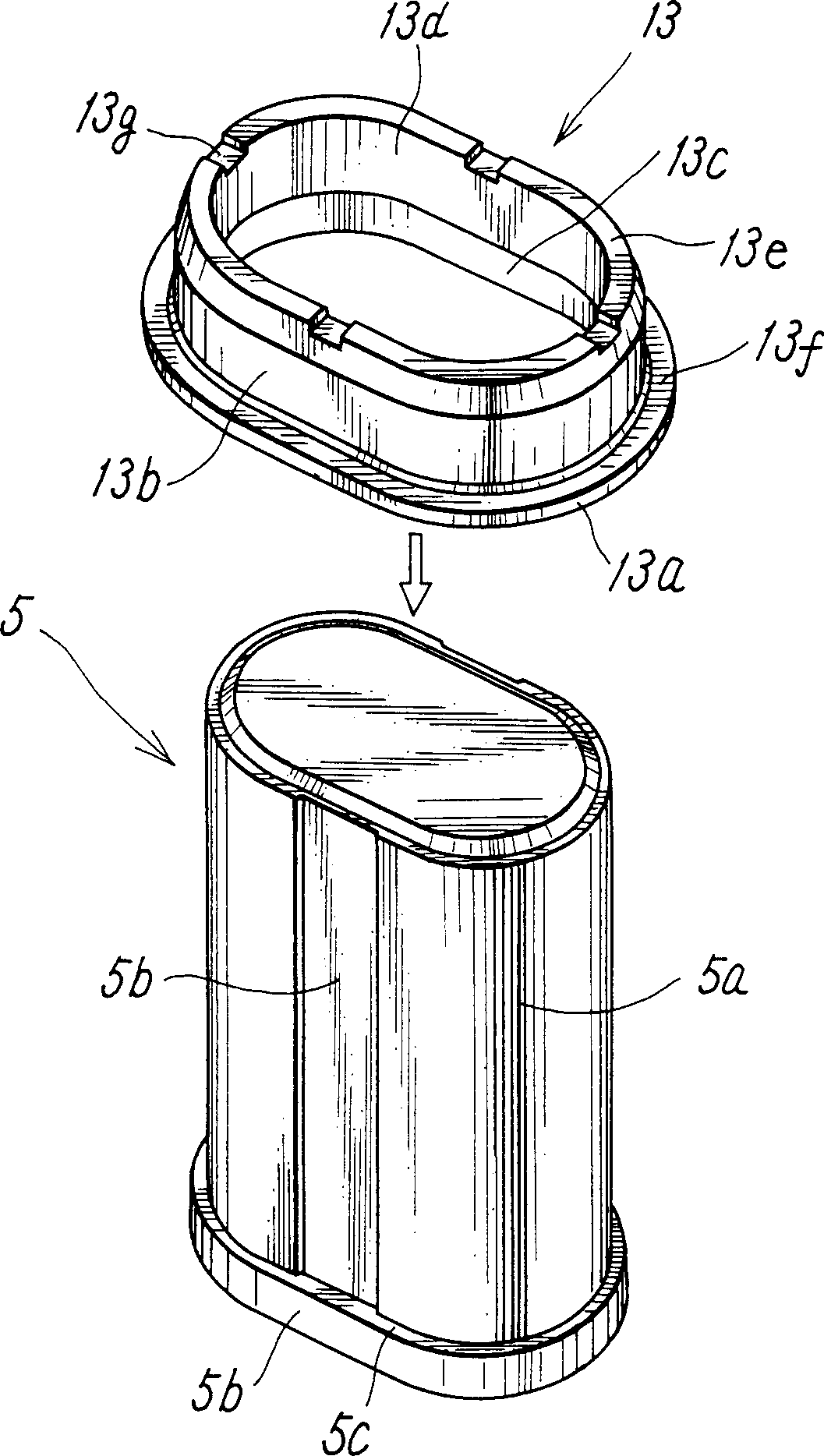

[0022] Inside the above-mentioned magnetic case 4, a non-magnetic bobbin 8 having an oblong center hole 8a in the center and a coil 7 wound around the outer periphery is provided, and is connected in a state of being in contact with the end surface of the bobbin 8. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com