Rear portion of vehicle and assembly method thereof

A structure and vehicle technology, applied to vehicle components, upper structure, upper structure sub-assembly, etc., can solve the problems of reduced workability of roof molding, car body assembly, easy displacement of hinge cover, etc., and achieve the degree of freedom of setting Improvement, appearance improvement, and the effect of suppressing the occurrence of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

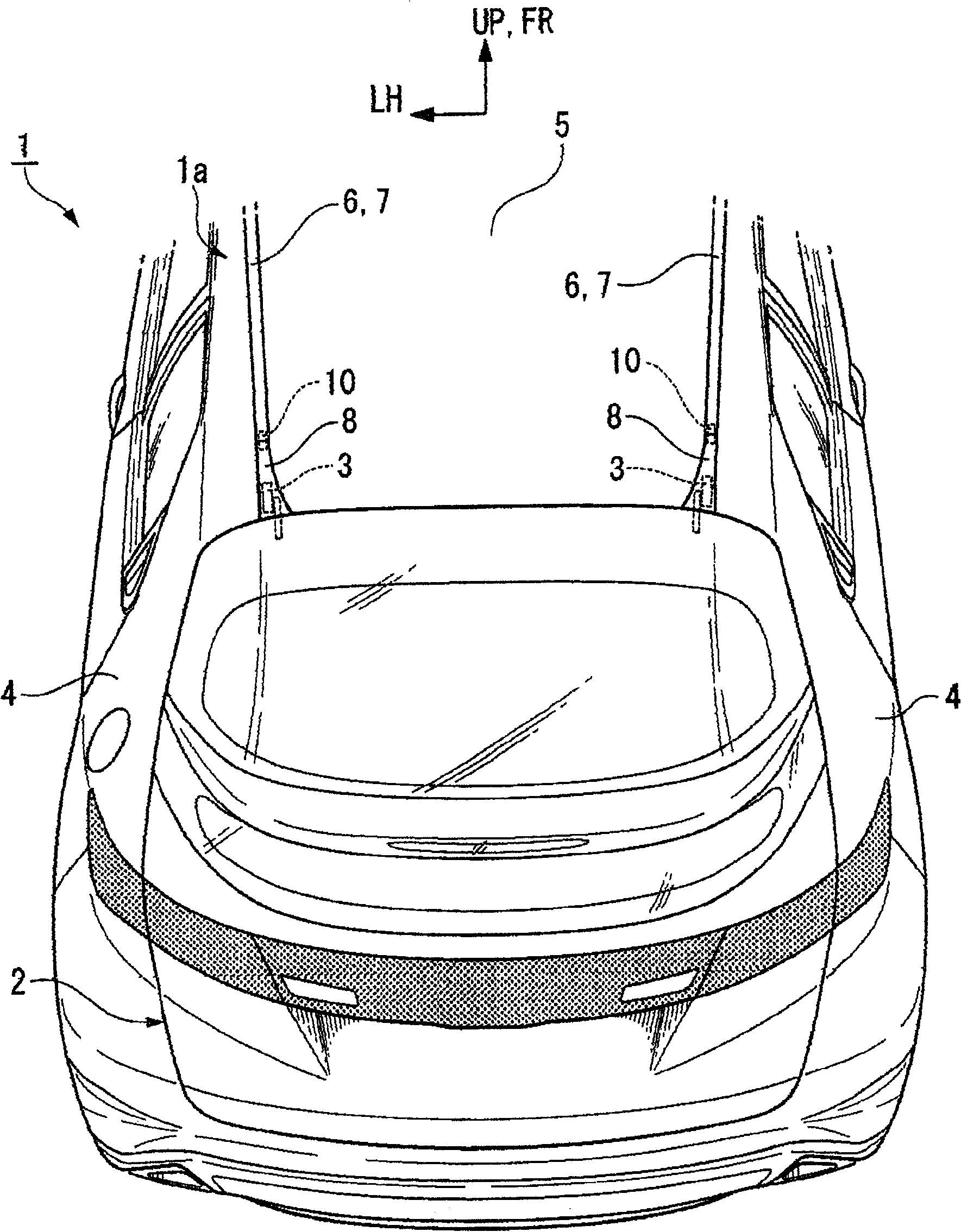

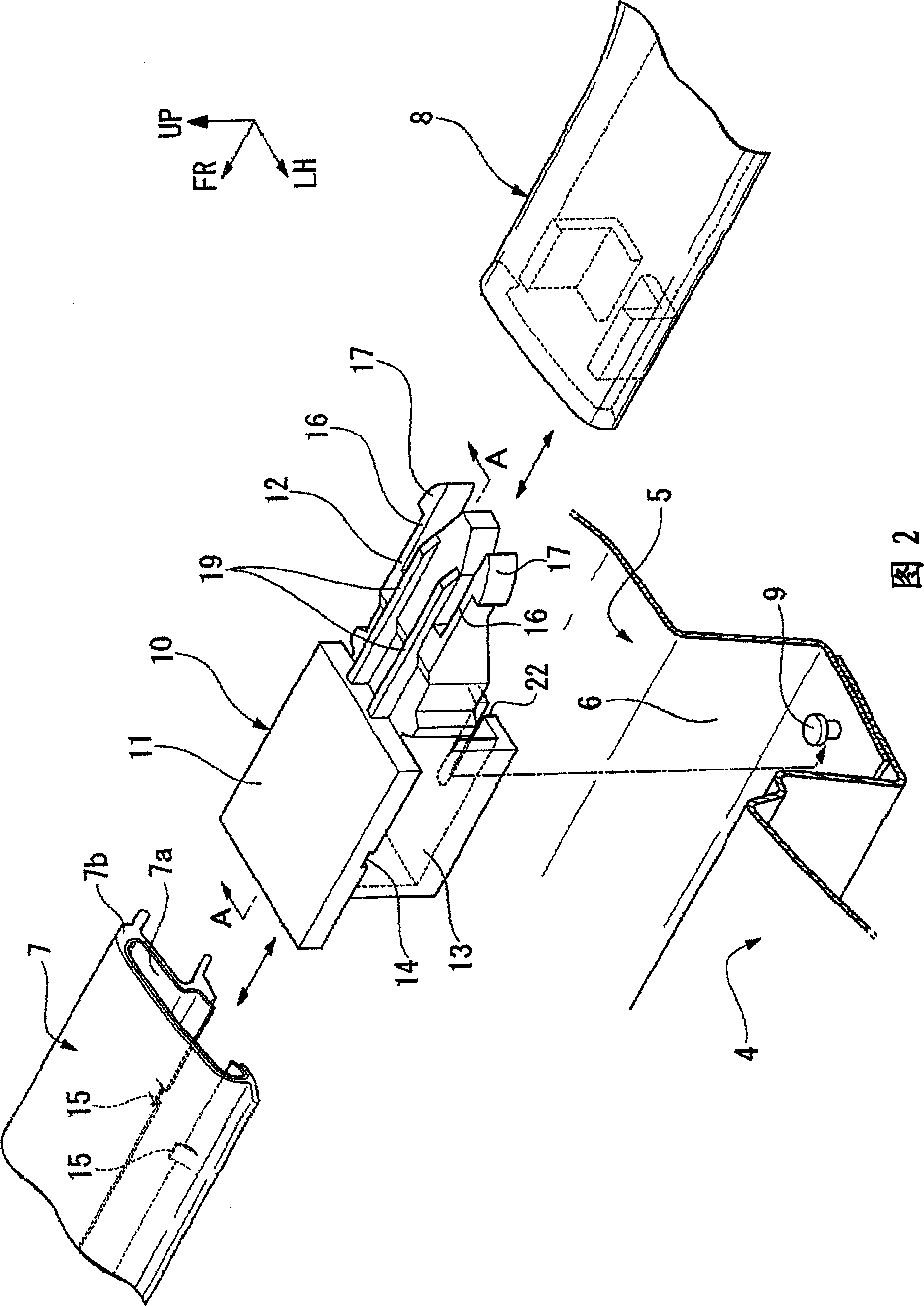

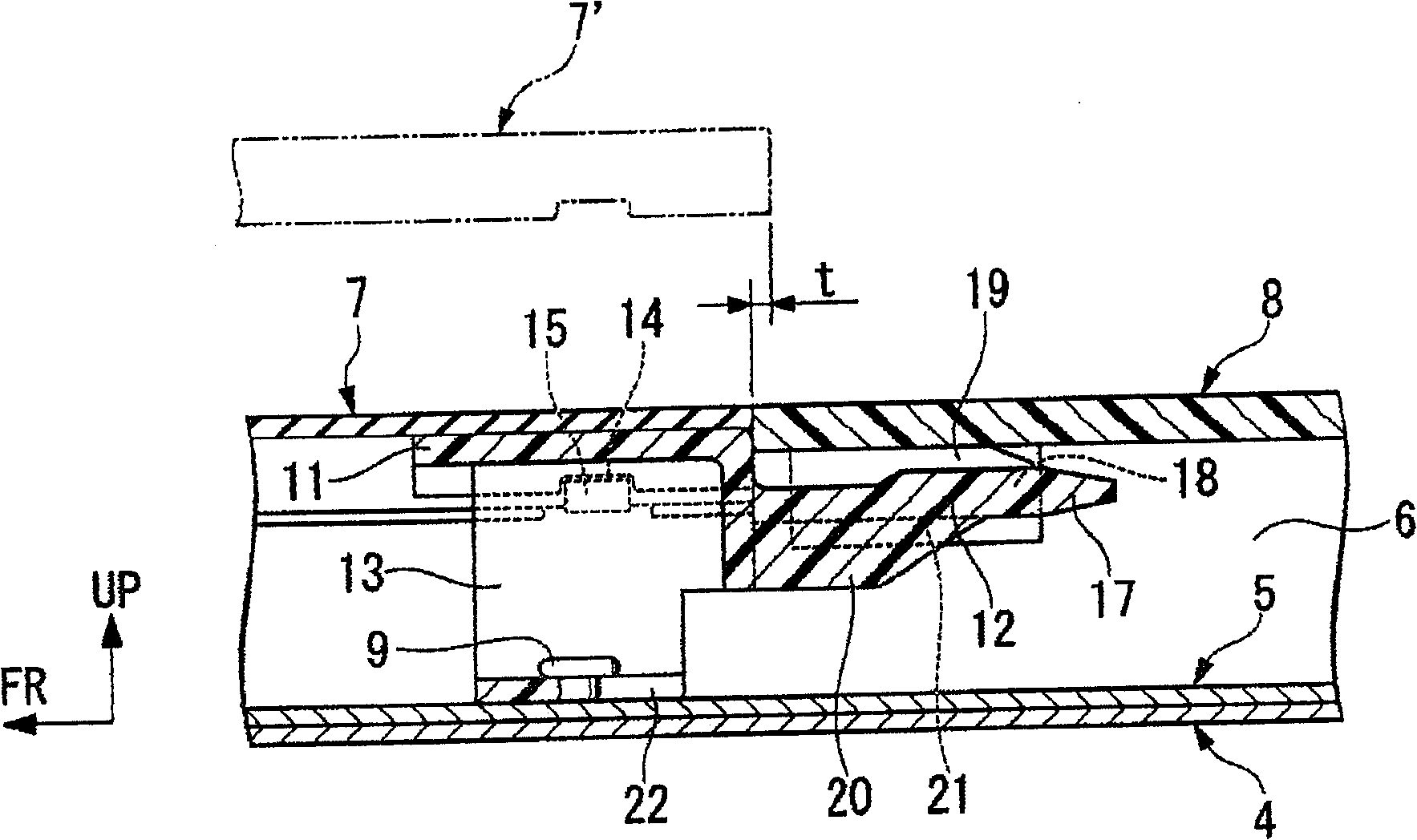

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, directions such as front, rear, left, and right in the following description are the same as directions of the vehicle unless otherwise specified. In addition, in the drawings, arrow FR indicates the front of the vehicle, arrow LH indicates the left side of the vehicle, and arrow UP indicates the upper side of the vehicle.

[0039] figure 1 The illustrated vehicle 1 has a monocoque body 1 a formed by integrally joining panel members and body frame members, and a rear opening at a rear end thereof is opened and closed by a tailgate 2 . The tailgate 2 is opened and closed so that the lower edge can swing up and down about a left-right hinge axis along the upper edge. The upper end of tailgate 2 is connected on the upper edge of the above-mentioned rear opening by a pair of left and right tailgate hinges (hinge structure) 3, which can freely rotate relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com